Chlorinated vinyl chloride-based resin

A chlorinated polyvinyl chloride and resin technology, applied in the field of chlorinated polyvinyl chloride series resin, can solve the problems of mold surface pollution, high chlorination, a large amount of hydrogen chloride gas, etc., and achieve the effect of excellent continuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0154] In a glass-lined reaction vessel with an inner volume of 300 L, 130 kg of ion-exchanged water and 50 kg of polyvinyl chloride resin with an average degree of polymerization of 1000 were poured into the reaction vessel, and stirred to disperse the polyvinyl chloride resin in water to form a water suspension state. The temperature of the aqueous suspension was raised to 100°C. Next, after reducing the pressure in the reaction vessel to remove oxygen (oxygen amount 100ppm), it was stirred so that the volume of the vortex generated at the gas-liquid interface by stirring became 8.2L, and the chlorine partial pressure became 0.40MPa. Chlorine (oxygen content 50ppm) is introduced in the way, and thermal chlorination is started.

[0155] Then, the chlorination temperature was kept at 100° C., the chlorine partial pressure was kept at 0.40 MPa, and after the amount of added chlorination reached 4.0% by mass, it became 15 ppm / Hr in terms of hydrogen peroxide relative to the poly...

Embodiment 2~8、 comparative example 1~6

[0158] The average degree of polymerization of the raw material PVC, the reaction temperature, the vortex volume during stirring, the average chlorine consumption rate and the addition chlorination amount are set as Table 1 and Table 2, except that, operate in the same way as in Example 1 to obtain Chlorinated polyvinyl chloride resin.

[0159] (evaluate)

[0160] The following evaluations were performed on the chlorinated polyvinyl chloride-based resins obtained in Examples and Comparative Examples. The results are shown in Table 1 and Table 2.

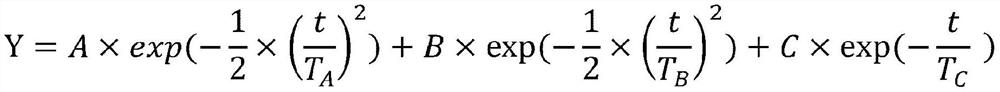

[0161] (1) Pulse NMR measurement

[0162] The obtained powdery chlorinated polyvinyl chloride resin was introduced into a glass sample tube with a diameter of 10 mm (manufactured by BRUKER, model 1824511, diameter 10 mm, length 180 mm, plate bottom). The sample tube was set in a pulsed NMR apparatus ("the minispec mq20" manufactured by BRUKER Corporation), and the temperature was raised stepwise to 30°C (hold for 10 minutes), 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com