Fabrication process of semi-solid copper alloy multi-channel valve body by radial forging strain induction method

A strain-induced, copper alloy technology, used in valve devices, metal processing equipment, etc., can solve the problems of inability to produce large-scale semi-solid billets in large quantities, severe mechanical stirrers, and large plastic deformation forces. Stable, low cost, low deformation resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

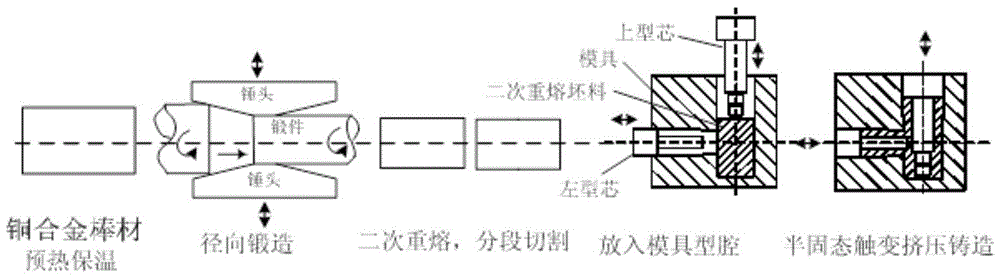

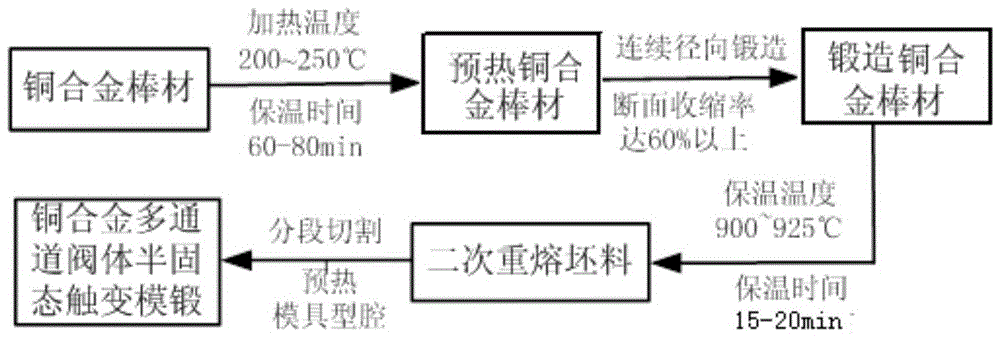

[0017] refer to figure 1 with figure 2 , taking a Φ150mm copper alloy rod as an example, the process of preparing a semi-solid copper alloy multi-channel valve body by radial forging strain induction method includes the following steps:

[0018] 1) Preheat the copper alloy rod, heat the Φ150mm copper alloy rod to 200-250°C with the furnace, and keep it warm for 60-80 minutes to ensure that the entire billet is heated through;

[0019] 2) Carry out radial forging on the copper alloy rod, take out the preheated copper alloy rod through the manipulator and feed it in the axial direction by clamping and rotating. The four hammerheads of the radial forging machine are symmetrically distributed around the billet, Carry out high-frequency reciprocating forging to make the billet elongate and thinner under the condition of multi-head spiral extension deformation, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com