Etching liquid for semiconductor substrate

An etchant and semiconductor technology, applied in the field of etchant for semiconductor substrates for solar cells, etch force recovery agent, and semiconductor substrates for solar cells, to achieve the effects of reducing waste water treatment load, low light reflectivity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~23 and comparative example 1~10

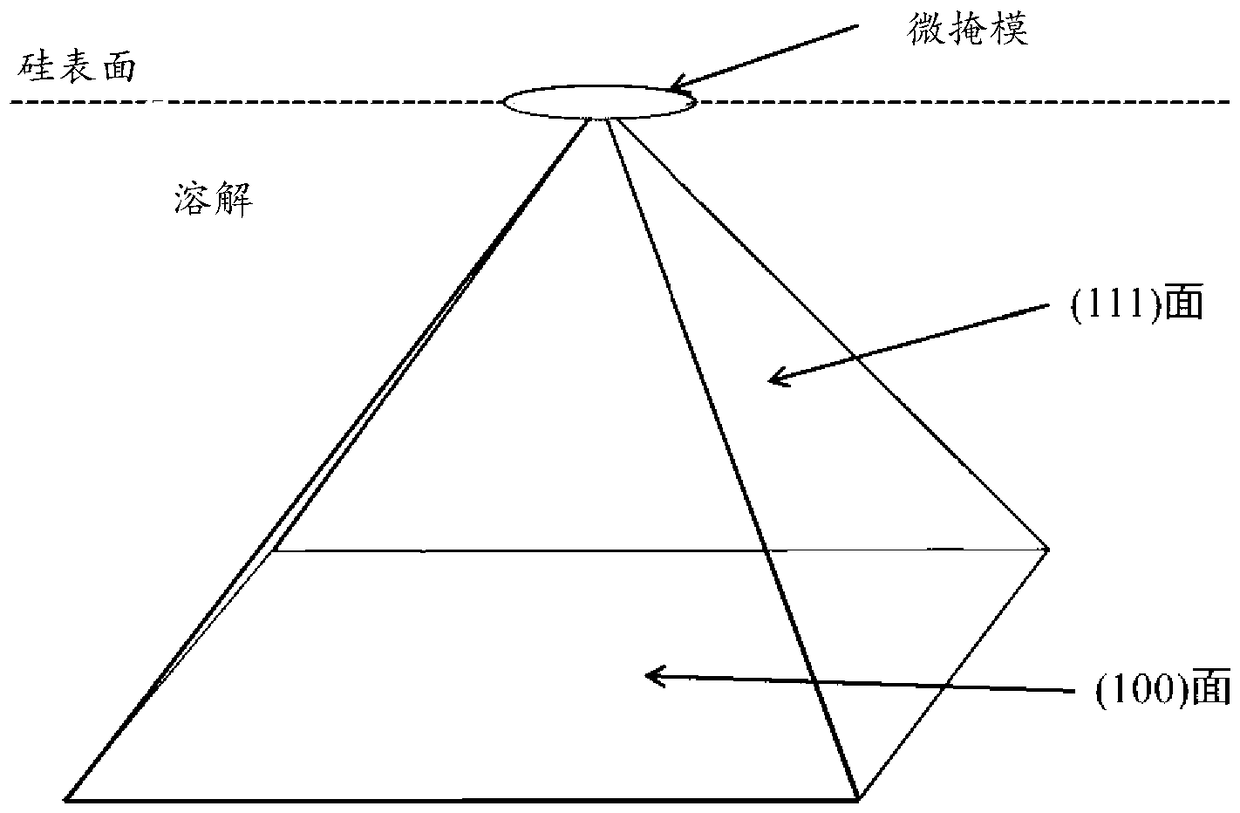

[0152] An n-type monocrystalline silicon substrate (a square with a side length of 125 mm and a thickness of 160 mm) with a crystal orientation (100) plane on the surface mu m substrate) in the conditions shown in Table 1A, that is, at 50 to 90° C., immersed in an etching solution prepared according to the blend composition shown in Table 1A for 1 to 40 minutes. The etched substrate surface was observed visually, with a laser microscope and a scanning electron microscope, and the results are shown in Table 1B. The chelating agent used (Additive 2) was DTPA (diethylenetriaminepentaacetic acid). In addition, the operation of a specific etching process is as described in the following [etching process]. The pH value of the etching solution in these examples and comparative examples is in the range of 12 to 14 at 25°C.

[0153] In addition, sodium sulfite (Example 2, Example 20, and Comparative Example 5) or sodium ascorbate (Example 10) was contained in the etching solution at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com