Preparation and calibration method of metalized germanium telluride under non-static pressure condition

A germanium telluride and metallization technology, which is applied in the direction of metal selenide/telluride, binary selenium/telluride compound, instruments, etc., can solve the problems of low pressure, sample short circuit, cost increase, etc., and achieve high optical transmittance , good insulation and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The preparation and calibration method of metallized germanium telluride under non-static pressure conditions of a typical phase change material of the present invention: it includes:

[0050] 1. High pressure preparation:

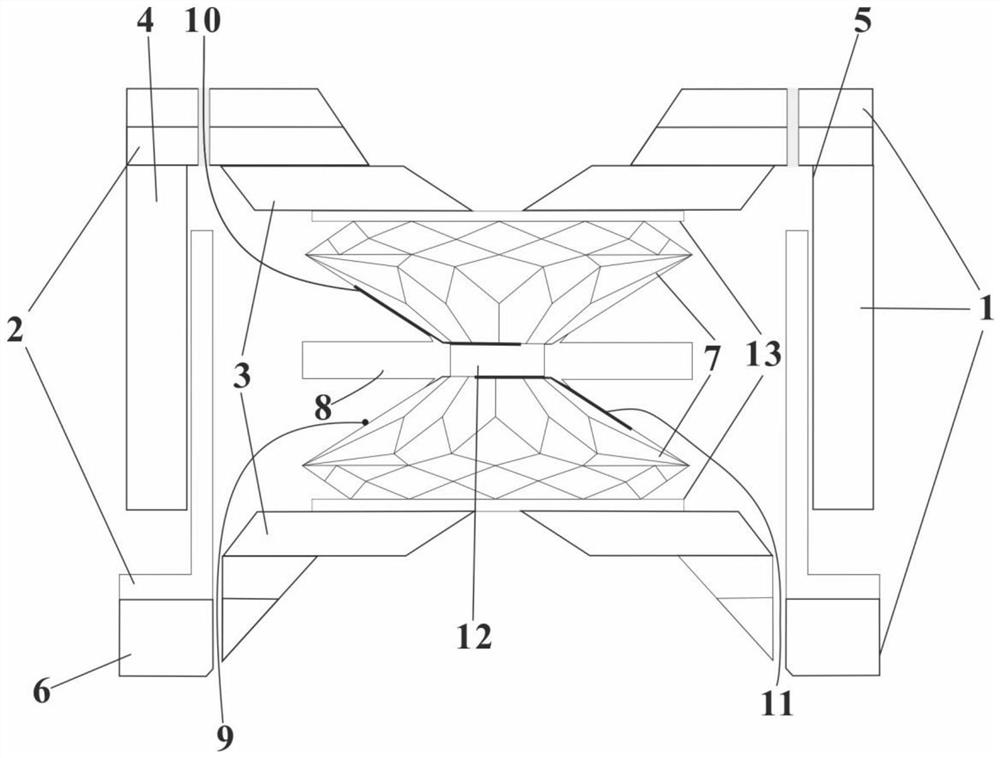

[0051] (1) In order to meet the requirements of the present invention, the present invention adopts a self-improved four-column press to carry out experiments, and the improved four-column diamond pressure chamber high temperature and high pressure experimental equipment is shown in figure 1 , the specific improvement plan is to open four symmetrical round holes (hole diameter is 1.0mm) on the alloy steel and beryllium copper of the upper and lower support blocks of the original press, so as to facilitate the extraction of electrode leads and thermocouple leads during the experiment. And magnetron sputtering aluminum oxide thin film insulation powder on its surface, so that the measurement circuit has better insulation during the experiment. At the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com