Nano-silver modified titanium oxide nanotube array, preparation method and application thereof

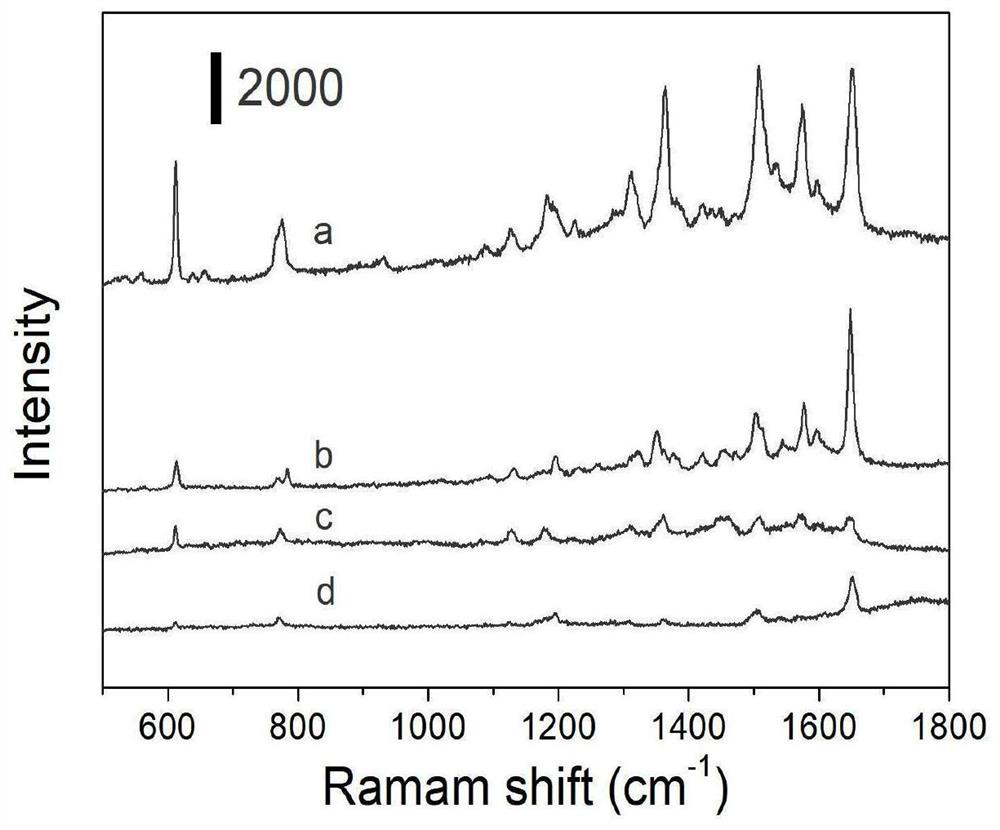

A technology of titanium oxide nanotubes and nano-silver, which is applied in the field of nano-materials, can solve the problems of affecting photocatalytic performance and SERS performance, reducing photocatalytic performance and SERS performance, and difficult to modify silver nanoparticles, so as to achieve easy promotion and use, and low cost. Low, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

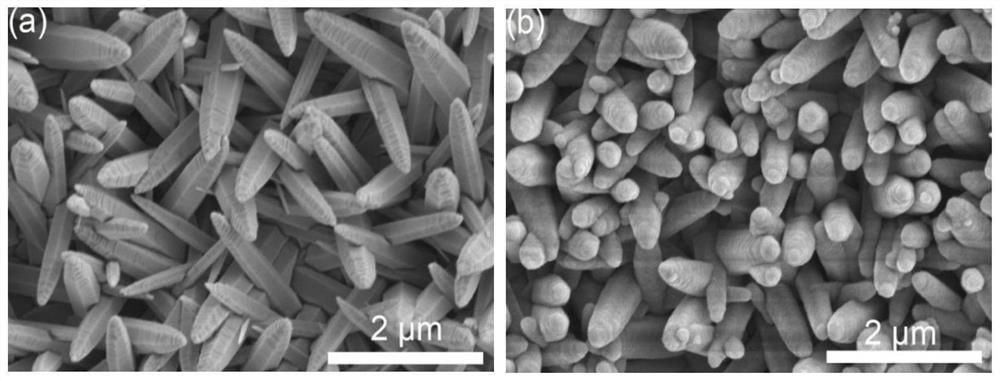

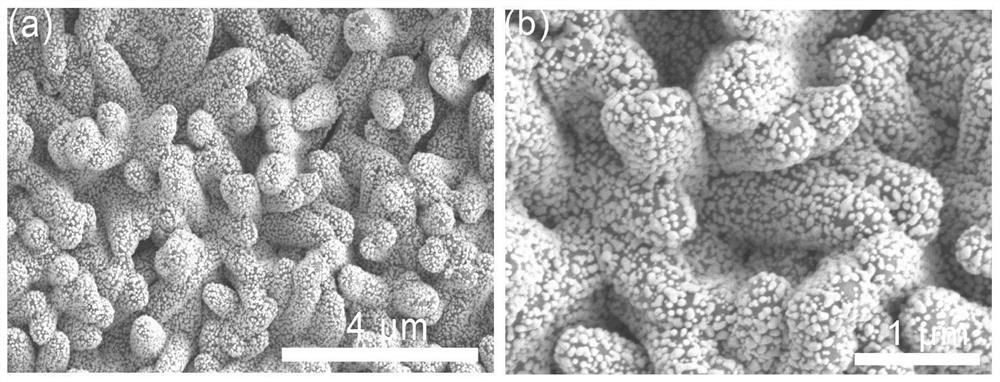

[0035] The silicon wafer substrate is selected as the conductive substrate, and the specific steps of preparation are as follows:

[0036] 01. Use plasma to bombard the conductive surface of the conductive substrate in an oxygen atmosphere for 240 seconds to increase the hydrophilicity of the surface. After the bombardment, clean the surface of the conductive substrate once with deionized water and dry it in an oven at 60°C Dry;

[0037] 02. Preparation of zinc oxide nanorod arrays: Add 100ml of water into 0.008mol zinc nitrate hexahydrate, after fully dissolving, add 10wt% ammonia water drop by drop to make it clear, and place the conductive The substrate was vertically placed in the zinc ammonia solution, and zinc oxide nanorods were grown on the surface of the conductive substrate for 60 minutes. After the reaction, the surface of the conductive substrate on which the ZnO nanorod arrays were grown was washed once with deionized water, and then dried at room temperature.

...

Embodiment 2

[0041] The indium tin oxide glass substrate is selected as the conductive bottom, and the specific steps of preparation are as follows:

[0042] 01. Use plasma to bombard the conductive surface of the conductive substrate for 300s in an oxygen atmosphere to increase the hydrophilicity of the surface. After the bombardment, clean the surface of the conductive substrate twice with deionized water and bake in an oven at 60°C Dry;

[0043] 02. Preparation of zinc oxide nanorod arrays: Add 100ml of water into 0.010mol of zinc nitrate hexahydrate. After fully dissolving, add 10wt% ammonia water drop by drop to make it clear. The substrate was vertically placed in the zinc ammonia solution, and zinc oxide nanorods were grown on the surface of the conductive substrate for 75 minutes. After the reaction, the surface of the conductive substrate on which the ZnO nanorod arrays were grown was washed twice with deionized water, and then dried at room temperature.

[0044] 03. Preparation...

Embodiment 3

[0047] The indium tin oxide glass substrate is selected as the conductive substrate, and the specific steps of preparation are as follows:

[0048] 01. Use plasma to bombard the conductive surface of the conductive substrate for 360s in an oxygen atmosphere to increase the hydrophilicity of the surface. After the bombardment, clean the conductive surface with deionized water for 3 times, and bake in an oven at 60°C Dry;

[0049] 02. Preparation of zinc oxide nanorod arrays: Add 100ml of water into 0.012mol of zinc nitrate hexahydrate. After fully dissolving, add 10wt% ammonia water drop by drop to make it clear. The substrate was vertically placed in the zinc ammonia solution, and zinc oxide nanorods were grown on the surface of the conductive substrate for 90 minutes. After the reaction, the surface of the conductive substrate on which the ZnO nanorod arrays were grown was washed with deionized water for 3 times, and then dried at room temperature.

[0050] 03. Preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com