Modified liquid metal composite material capable of being directly formed and preparation method thereof

A technology of liquid metal and composite materials, applied in the direction of replication/marking methods, heat exchange materials, chemical instruments and methods, etc., can solve the problem of the mismatch of interfacial tension between liquid metal and polymer matrix, the difficulty of direct forming of liquid metal, and the hindrance of liquid state Metal application and other problems, to achieve the effect of fluidity, good plasticity and low tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

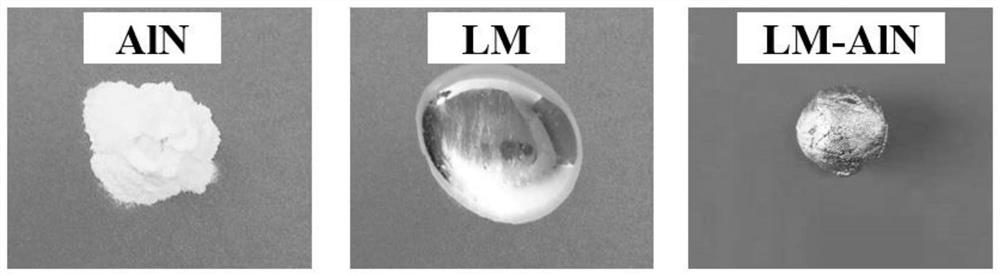

[0033] Embodiment 1: putty state liquid metal-aluminum nitride (0.4972m 2 / g) Preparation of (LM-AlN) liquid metal matrix composites and its application in thermally conductive materials:

[0034]Add 15g of aluminum nitride and 24g of gallium indium tin liquid metal into a mortar, grind for 20 minutes and mix well to obtain a putty-like mixture. In order to disperse the aluminum nitride more uniformly in the liquid metal matrix, the mixture is then transferred to a mixer, and mixed to obtain a putty-like LM-AlN liquid metal matrix composite. The thermal conductivity of the obtained composite is 52.16 W / m K.

Embodiment 2

[0035] Embodiment 2: putty state liquid metal-alumina (0.7726m 2 / g)(LM-Al 2 o 3 ) Preparation of liquid metal matrix composites and their application in thermally conductive materials:

[0036] Add 14g of alumina and 20g of gallium indium tin liquid metal into a mortar, grind for 20 minutes and mix well to obtain a putty-like mixture. In order to disperse aluminum oxide more uniformly in the liquid metal matrix, transfer the mixture to a mixer and mix to obtain putty-like LM-Al 2 o 3 Liquid metal matrix composites. The thermal conductivity of the obtained composite is 17.74 W / m K.

Embodiment 3

[0037] Embodiment 3: putty state liquid metal-silicon nitride (1.7717m 2 / g)(LM-Si 3 N 4 ) Preparation of liquid metal matrix composites and their application in thermally conductive materials:

[0038] Add 12g of silicon nitride and 20g of gallium indium liquid metal into a mortar, grind for 20 minutes and mix well to obtain a putty-like mixture. In order to disperse the aluminum nitride in the liquid metal matrix more uniformly, the mixture is then transferred to a mixer, and mixed to obtain a putty-like LM-TiN liquid metal matrix composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com