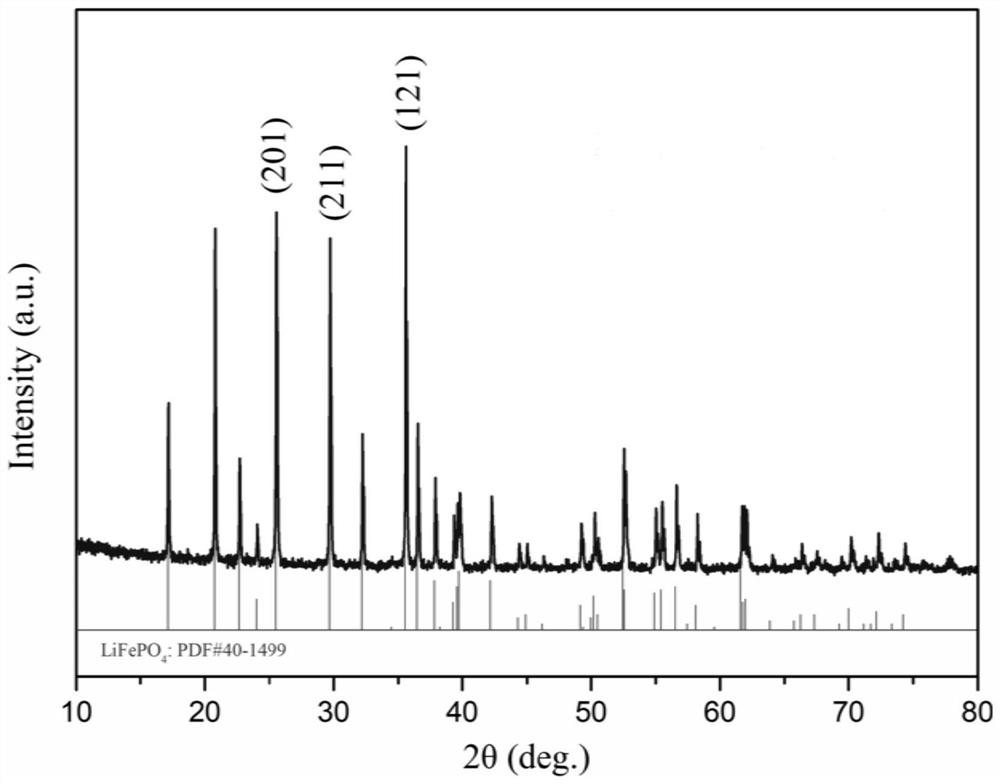

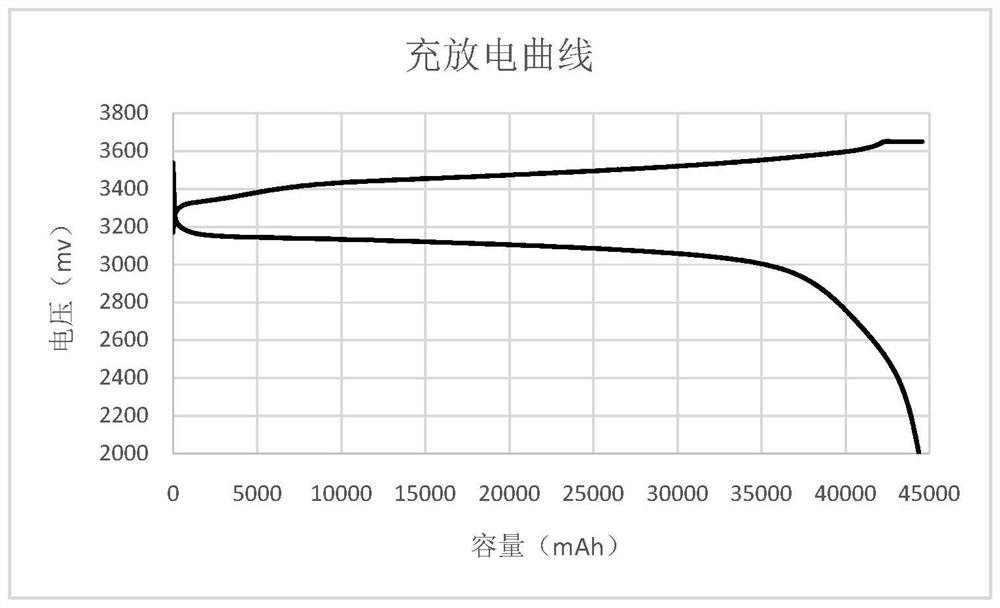

Nanometer lithium iron phosphate with high capacity, high compaction density and high iron-phosphorus ratio, and preparation method of nanometer lithium iron phosphate

A lithium iron phosphate, high-pressure compaction technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, to achieve the effect of facilitating insertion and extraction, uniform and fine particles, and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] According to a typical implementation of the embodiment of the present invention, a method for preparing nano-lithium iron phosphate with high capacity, high compacted density and high iron-phosphorus ratio is provided, such as Figure 4 As shown, the method includes:

[0037] Step S1, mixing the phosphorus salt solution and the iron salt solution to perform an oxidation reaction to obtain an oxidation slurry;

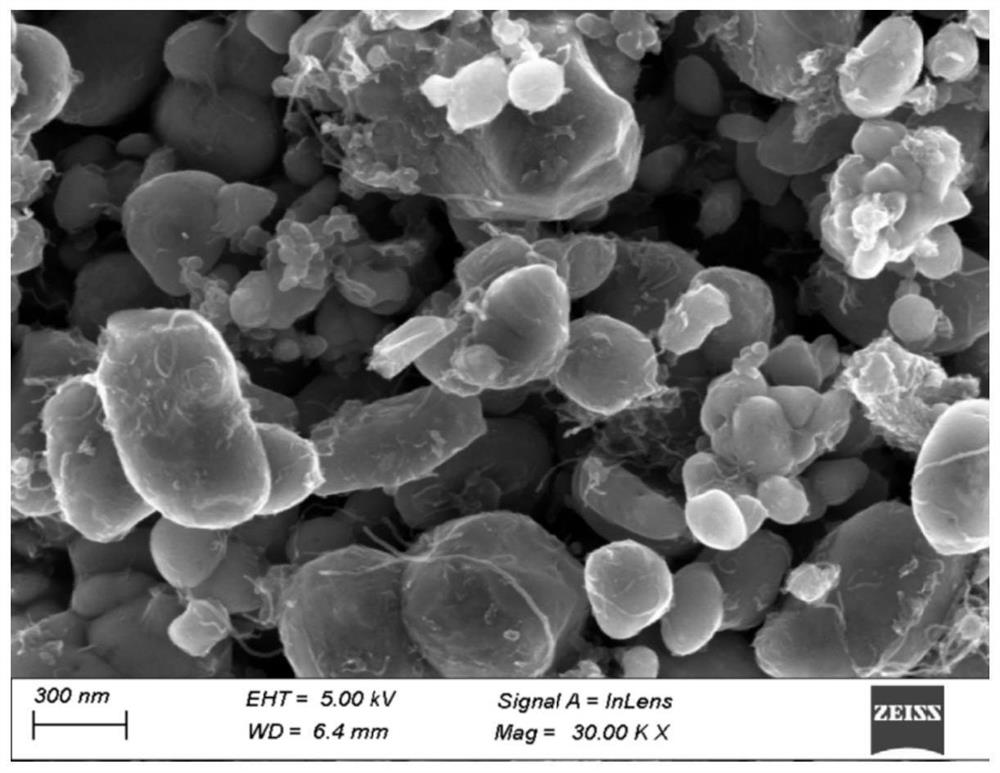

[0038] Step S2, performing the first grinding on the oxidized slurry to obtain oxidized slurry with fine particle size, and the oxidized slurry with fine particle size satisfies: D99≤1μm, D50≤300nm;

[0039] Step S3, after first washing the fine particle size slurry, adding pure water and phosphoric acid to carry out conversion reaction to obtain converted slurry;

[0040] Step S4, adjusting the pH of the converted slurry to 6-8, and then performing the second grinding to obtain the converted slurry with fine particle size, and the converted slurry with fine part...

Embodiment approach

[0058] The preparation method of described iron salt solution is: FeSO 4 or FeSO 4 7H 2 O is dissolved in pure water, and filtered to obtain the iron salt solution, in which FeSO 4 The concentration is 0.5~2mol / L;

[0059] The preparation method of the phosphorus salt solution is as follows: dissolving MAP or DAP in pure water, adjusting the pH to 6-8 with ammonia water or phosphoric acid, adding hydrogen peroxide and stirring evenly to obtain a phosphorus salt solution, and the P content in the phosphorus salt solution is 1~4mol / L, the substance concentration of hydrogen peroxide in the phosphorus salt solution is 0.55~0.65 times of P content;

[0060] In other embodiments, other methods may also be used to obtain the phosphorus salt solution and the iron salt solution.

[0061] As an optional implementation manner, in the step S3,

[0062] The first washing includes: filtering the fine particle size slurry and washing with pure water, and the end point of the washing i...

Embodiment 1

[0080] An embodiment of the present invention provides a method for preparing nano-lithium iron phosphate with high capacity, high compaction density and high iron-phosphorus ratio, the method comprising:

[0081]1. Preparation of anhydrous iron phosphate

[0082] Step S1, adding the phosphorus salt solution dropwise to the iron salt solution, the ratio of the amount of phosphorus to iron is (1-1.05):1, the stirring speed is 200rpm, and the reaction time is 0.5-3h to generate amorphous iron phosphate, and obtain Oxidized slurry; where,

[0083] Iron source preparation method is: FeSO 4 or FeSO 4 ·7H 2 O is dissolved in pure water, and filtered to obtain the iron salt solution, in which FeSO 4 The concentration is 0.5~2mol / L;

[0084] The preparation method of the phosphorus source is: dissolving MAP or DAP in pure water, adjusting the pH to 6-8 with ammonia water or phosphoric acid, adding hydrogen peroxide and stirring evenly to obtain a phosphorus salt solution, the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com