Symmetrical tetraphenyl phenyl vinyl silicone oil and preparation method thereof

A technology of phenylvinyl silicon and polyvinyl silicone oil, which is applied in the field of synthesizing symmetrical tetraphenyl phenyl vinyl and its preparation, can solve the problems of increasing system viscosity, unevenness, affecting process performance, etc., and achieve improvement The effect of bond strength and strong thermal deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

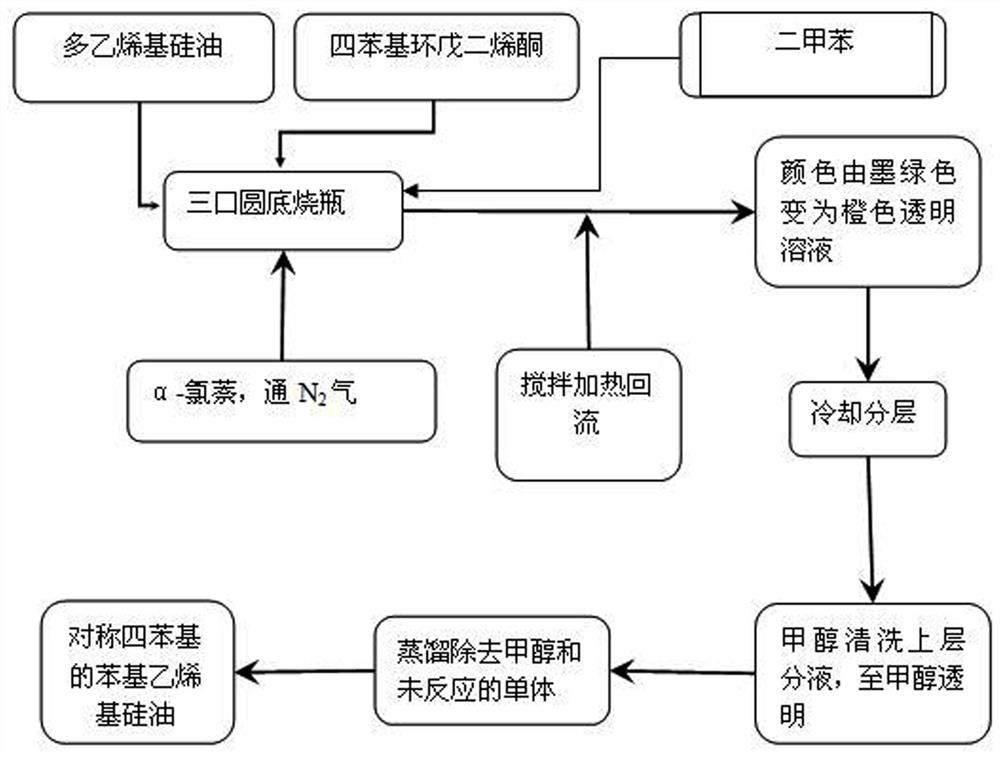

Method used

Image

Examples

Embodiment 1

[0029] Put 5 parts of tetraphenylcyclopentadienone powder and 50 parts of xylene into a 200ml three-necked flask with a condensation reflux device, magnetic stirring and ventilation device, and keep the temperature at 50°C until the tetraphenylcyclopentadienone is completely After dissolving, heat up to 75°C, slowly add 20 parts of polyvinyl silicone oil (containing 0.04 mol / L of vinyl group) into the system, stir for 5min after the dropwise addition, and slowly drop 1 part of α-chloronaphthalene in 20min Add it to the three-necked flask, introduce nitrogen (speed 1m / s), heat up to 155°C to continue the reaction, when the color of the reaction system turns dark green into an orange transparent solution, heat up to 220°C and continue the reaction for 15 hours, stop the reaction, slowly Cool the product to 20°C, place the product in a separatory funnel and stand for layers, collect the upper layer product, wash the collected upper layer product with methanol until transparent, an...

Embodiment 2

[0031] Put 5 parts of tetraphenylcyclopentadienone powder and 60 parts of xylene into a 200ml three-necked flask with a condensation reflux device, magnetic stirring and ventilation device, and keep it at a constant temperature of 50 ° C until the tetraphenylcyclopentadienone is completely After dissolving, the temperature was raised to 85°C, and 25 parts of polyvinyl silicone oil (containing 0.04 mol / L of vinyl group) was slowly added to the system. Add it to the three-necked flask, introduce nitrogen (speed 1.5m / s), heat up to 165°C to continue the reaction, when the color of the reaction system turns dark green into an orange transparent solution, heat it up to 220°C and continue the reaction for 15 hours, stop the reaction, The product was slowly cooled to 20°C, the product was placed in a separatory funnel and then left to stand for stratification, the upper layer product was collected, the collected upper layer product was washed with methanol until transparent, and metha...

Embodiment 3

[0033] Put 10 parts of tetraphenylcyclopentadienone powder and 80 parts of xylene into a 200ml three-necked flask with a condensation reflux device, magnetic stirring and ventilation device, and keep it at a constant temperature of 50 ° C until the tetraphenylcyclopentadienone is completely After dissolving, heat up to 75°C, slowly add 20 parts of polyvinyl silicone oil (containing 0.054 mol / L of vinyl group) into the system, stir for 5min after the dropwise addition, and slowly drop 2 parts of α-chloronaphthalene in 30min Add it to the three-necked flask, introduce nitrogen (speed 1.5m / s), heat up to 155°C to continue the reaction, when the color of the reaction system turns dark green into an orange transparent solution, heat up to 230°C and continue the reaction for 10 hours, stop the reaction, The product was slowly cooled to room temperature, the product was placed in a separatory funnel and then left to stand for stratification, the upper layer product was collected, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com