A hernia patch fixing nail and its preparation method

A technology for fixing nails and patches, applied in medical science, prostheses, etc., can solve the problems of non-absorbable patch sutures, long recovery time, large surgical incisions, etc., and achieve good mechanical strength, dimensional stability, and heat resistance Strong deformation ability, solve the effect of warping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

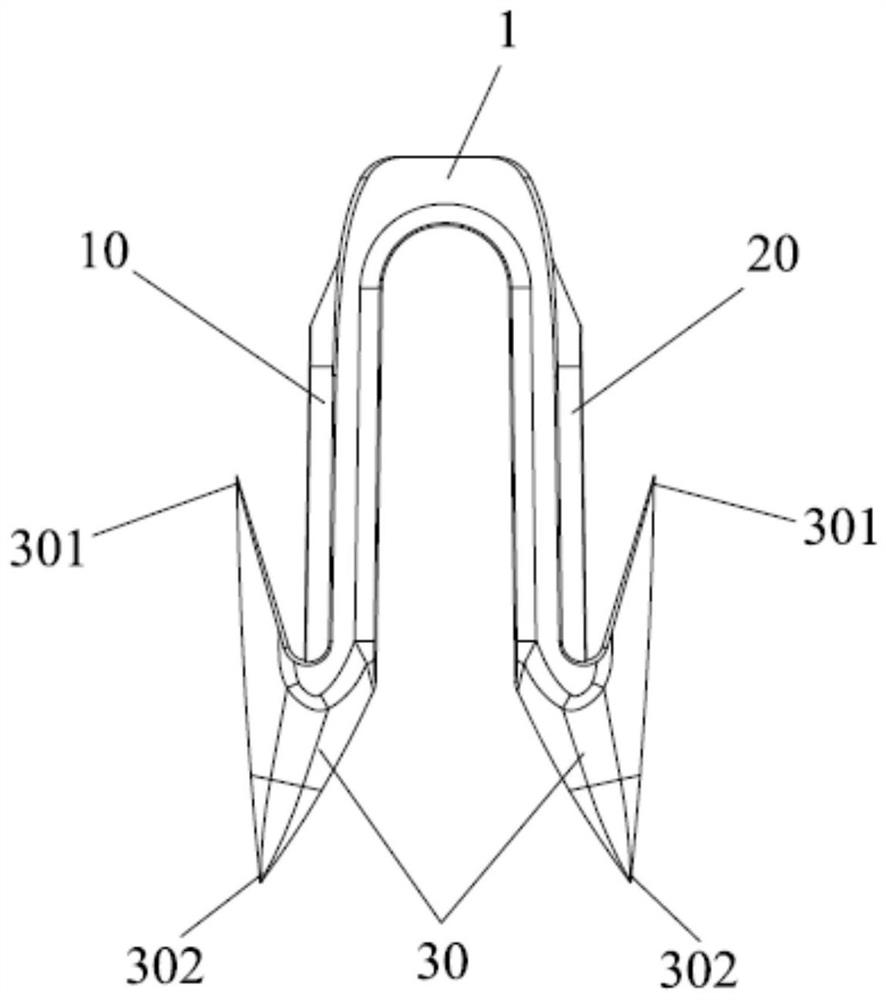

[0052] A kind of hernia patch fixation nail of the present embodiment, such as figure 1 As shown, the fixation nail 1 is integrally molded by absorbable biomaterials. The fixation nail 1 includes two fixation arms (10, 20) that are centrally symmetrical, and one end of each fixation arm (10, 20) extends outward. A hooked portion 30 that can embed and hook the skin at the repaired place is provided. The hooked portion 30 includes a front spine 301 located at the front end and a rear spine 302 located at the rear end respectively. The front spine 301 and the rear spine 302 are both sharp, so as to Reduce the resistance that the fixing nail 1 enters into the inside of the human body tissue. The hook portion 30 gradually extends outward from the front spine 301 to the rear spine 302, so that the fixation nail 1 cannot be withdrawn after entering the human tissue. In use, the hook portion 30 is inserted into human tissue from the front spine 301 .

[0053] The shape, size and thi...

Embodiment 2

[0055] A hernia patch fixing nail of this embodiment, the structure of the fixing nail is exactly the same as that of Example 1, wherein the absorbable biomaterial is a blend formed by a multiphase polymer composition, the preparation of the fixing nail Methods as below:

[0056] Step a, prepare general molecular weight rich lactide and low molecular weight rich lactide respectively according to the following steps:

[0057] a1) Polymerization reaction: adding molar percentage is 80% lactide and 20% glycolide in the stirred reactor, then adding dodecanol initiator and molar concentration is 0.33% stannous octoate solution as catalyst , carry out the reaction under inert conditions, first heat up to 120°C at a heating rate of 175°C / h, keep for a period of time until the monomer is completely melted, and then continue heating at a heating rate of 55°C / h until the melt reaches 175°C, keep for 3h;

[0058] Wherein: calculated by weight percentage, the amount of initiator used wh...

Embodiment 3

[0080]A hernia patch fixing nail of this embodiment, the structure of the fixing nail is exactly the same as that of Example 1, wherein the absorbable biomaterial is a blend formed by a multiphase polymer composition, the preparation of the fixing nail Methods as below:

[0081] Step a, prepare general molecular weight rich lactide and low molecular weight rich lactide respectively according to the following steps:

[0082] a1) Polymerization reaction: adding molar percentage is 85% lactide and 15% glycolide in stirred reactor, then adding dodecanol initiator and molar concentration is 0.30% stannous octoate solution, in Carry out the reaction under inert conditions, first heat up to 130°C at a heating rate of 185°C / h, keep for a period of time until the monomer is completely melted, then continue heating at a heating rate of 65°C / h until the melt reaches 185°C, and keep for 2 hours ; Wherein: calculated by weight percentage, the amount of initiator used when preparing genera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com