Rare earth complex/graphene oxide fluorescent material as well as preparation method and application thereof

A technology of rare earth complexes and fluorescent materials, which is applied in the field of fluorescent materials, can solve the problems of affecting the use of materials, easy phase separation, poor compatibility, etc., and achieves small steric hindrance, good conjugation and coplanarity, and increased The effect of the number of molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

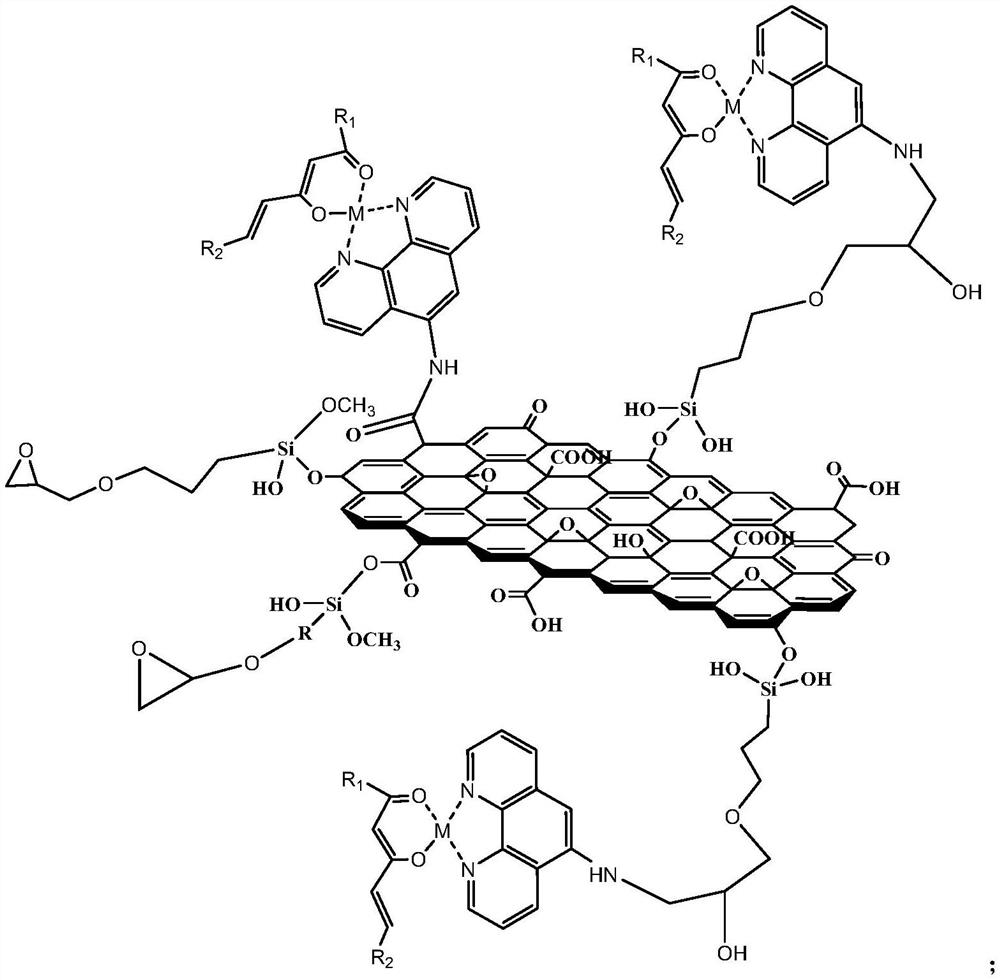

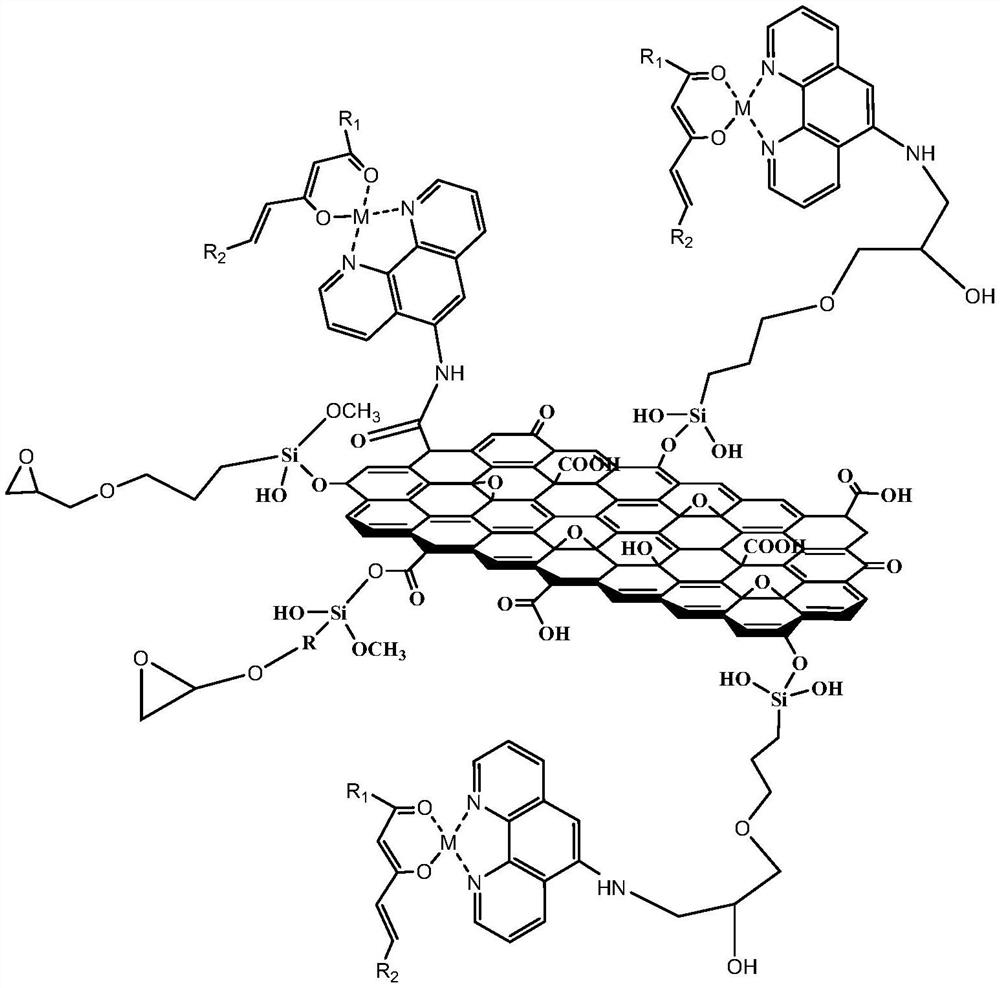

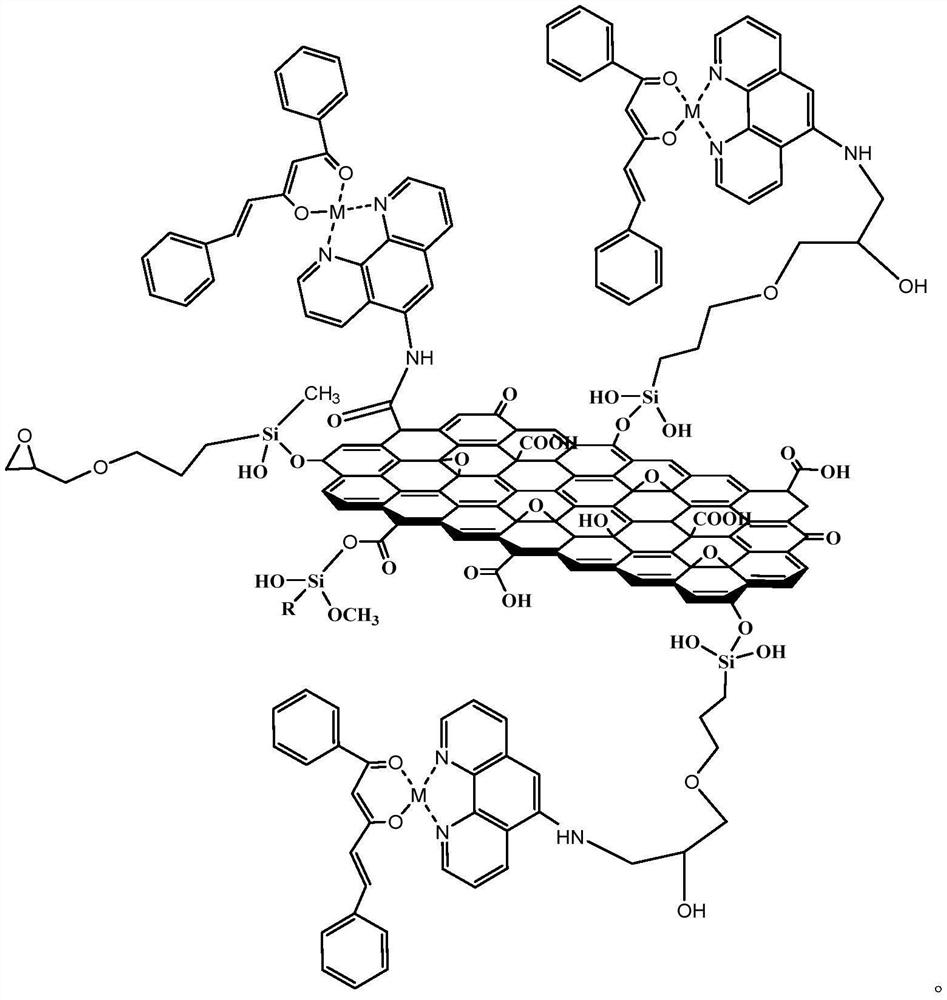

Image

Examples

Embodiment 1

[0041] (1) Preparation of europium complexes

[0042] 5g of sodium ethoxide, 80mL of tetrahydrofuran, 11mL of acetophenone and 15g of cinnamic acid were refluxed for 20 hours under the protection of nitrogen. After the reaction, the organic matter was extracted with ether, and then the ether was evaporated to obtain a viscous light yellow oily liquid. The long conjugated ligands were separated by silica gel column. Add 0.0050mol of long-conjugated ligand and 0.015mol of europium nitrate to 200mL of DMF for heating and stirring to dissolve, then dropwise add 120mL of 5-amino-1,10-phenanthroline solution, and heat to reflux for 0.5 h, after the reaction is finished, the product is separated and purified to obtain the europium complex.

[0043] The yield is 80%, and the melting point is 278-280°C.

[0044] (2) Preparation of silane coupling agent modified graphene oxide

[0045] After 1 g of graphene oxide was ultrasonically treated at 700 W for 15 min, it was dispersed in 50 g ...

Embodiment 2

[0050] (1) Preparation of europium complexes

[0051] 5g of sodium ethoxide, 80mL of tetrahydrofuran, 11mL of acetophenone and 15g of cinnamic acid were refluxed for 20 hours under the protection of nitrogen. After the reaction, the organic matter was extracted with ether, and then the ether was evaporated to obtain a viscous light yellow oily liquid. The long conjugated ligands were separated by silica gel column. Add 0.0200mol of long-conjugated ligand and 0.0050mol of europium nitrate to 200mL of tetrahydrofuran and 200mL of ethanol, heat and stir to dissolve, then add dropwise 30mL of 5-amino-1,10-phenanthroline solution, and heat after the dropwise addition Reflux reaction for 2 hours, after the reaction, separate and purify the product to obtain the europium complex.

[0052] The yield is 80%, and the melting point is 278-280°C.

[0053] (2) Preparation of silane coupling agent modified graphene oxide

[0054] After 1 g of graphene oxide was ultrasonically treated at ...

Embodiment 3

[0059] (1) Preparation of europium complexes

[0060] 5g of sodium ethoxide, 80mL of tetrahydrofuran, 11mL of acetophenone and 15g of cinnamic acid were refluxed for 20 hours under the protection of nitrogen. After the reaction, the organic matter was extracted with ether, and then the ether was evaporated to obtain a viscous light yellow oily liquid. The long conjugated ligands were separated by silica gel column. Add 0.0100mol of long-conjugated ligand and 0.0100mol of europium nitrate to 200mL of ethanol and 100mL of propanol, heat and stir to dissolve, then add 100mL of 5-amino-1,10-phenanthroline solution dropwise, and carry out Heating to reflux for 0.8h, after the reaction, separate and purify the product to obtain the europium complex.

[0061] The yield is 80%, and the melting point is 278-280°C.

[0062] (2) Preparation of silane coupling agent modified graphene oxide

[0063] After 1g of graphene oxide was ultrasonically treated at 700W for 25min, it was disperse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com