Aerated concrete production information digital control method

A technology of aerated concrete and production information, applied in the direction of electrical program control, program control, comprehensive factory control, etc., can solve the problems of lack of automatic error correction mechanism, blind spots in quality control, reinforcement errors, etc., to achieve product life Effectiveness of cycle management, reduced risk of equipment downtime, reduced chance of intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

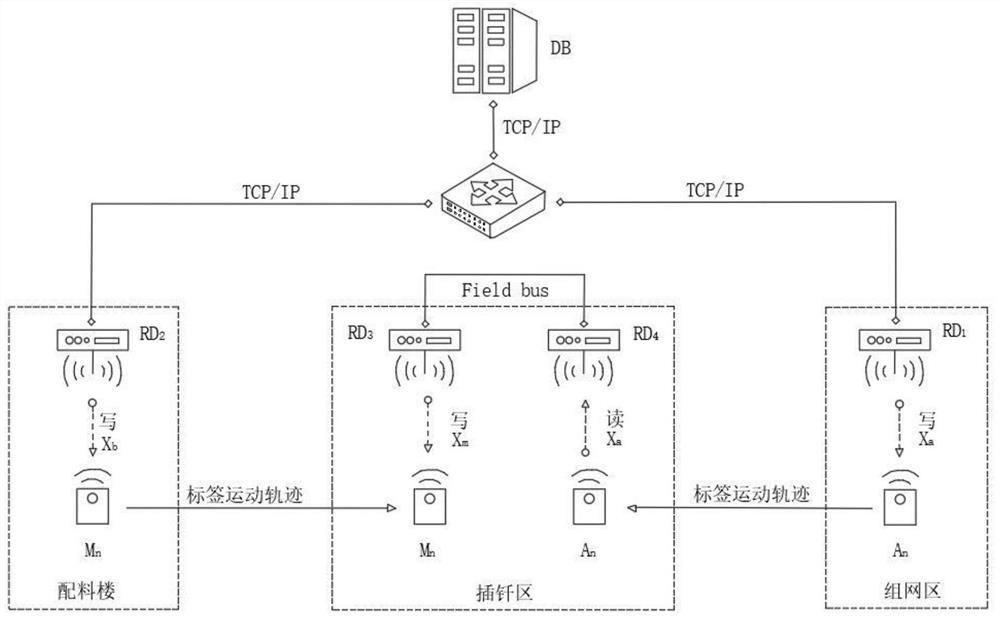

[0047] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0048] The present invention specifically uses information identification technology, including but not limited to: radio frequency technology, visual recognition technology, etc., database management technology, and cooperates with intelligent algorithms to complete the writing of production information and the reading and classification of product information. The number of mold cars 5 in the sky, the number of saddle seats 1, and the number of side plates 501 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com