Method for measuring content of aluminum in silicon-calcium alloy

A silicon-calcium alloy and aluminum content technology, applied in the field of element detection, can solve the problems of measurement interference, complex processing methods, and large amount of chemical reagents, so as to reduce instrument detection interference, improve efficiency and accuracy, and reduce types and dosages. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In the present invention, the preparation method of the flux preferably includes: grinding and mixing carbonate and boric acid.

[0048] In the present invention, the amount of the flux is preferably 0.4-0.6 g, more preferably 0.5 g, which can be determined according to the difficulty of sample digestion.

[0049] In the present invention, the mass ratio of the sample to be tested and the flux is preferably (0.1~0.2):(0.4~0.6), more preferably (0.12~0.18):(0.45~0.55), most preferably (0.14~ 0.16): 0.5.

[0050] The amount of flux used in the invention is small, which significantly reduces the interference caused by the mixed reagent matrix effect on the detection accuracy.

[0051]In the present invention, the melting is preferably high-temperature alkali fusion; the melting temperature is preferably 900-100°C, more preferably 920-980°C, more preferably 940-960°C, most preferably 950°C; The melting time is preferably 15-25 minutes, more preferably 18-22 minutes, most ...

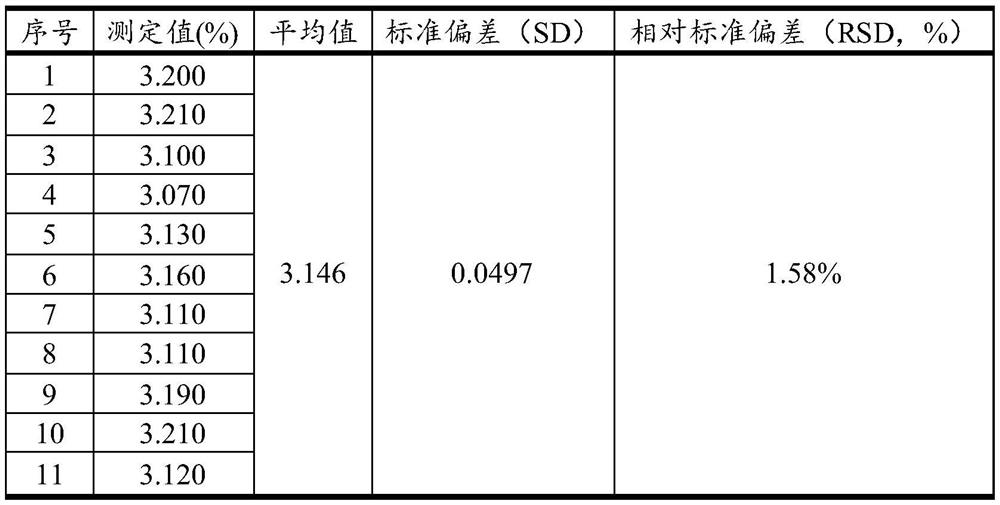

Embodiment 1

[0071] Weigh 0.10g silicon-calcium alloy sample to be tested, add 2ml hydrofluoric acid dropwise, after the reaction stops, heat it on the electric heating plate until it evaporates to dryness, add 0.4g anhydrous potassium carbonate and boric acid to grind and mix in a mass ratio of 1:1 Melt in a muffle furnace at 880°C for 20 minutes, add 12 ml of 1:1 hydrochloric acid solution (the volume ratio of hydrochloric acid and water is 1:1), and add an appropriate amount of ultrapure water during the dissolution process. Dilute it into a 100ml volumetric flask with ultrapure water, and finally measure the aluminum content with an inductively coupled plasma atomic emission spectrometer.

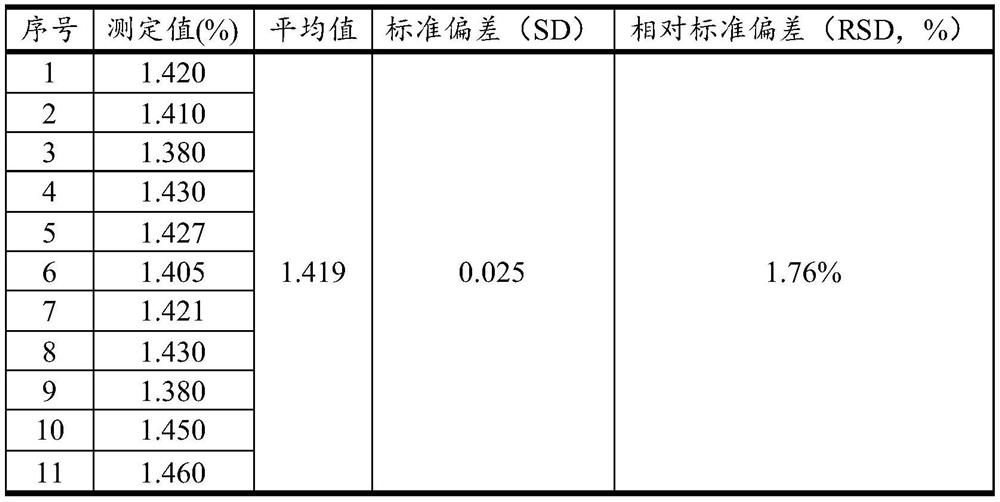

Embodiment 2

[0073] Weigh 0.15g of calcium-silicon alloy sample to be tested, add 2.5ml of hydrofluoric acid dropwise, after the reaction stops, heat it on the electric heating plate until it evaporates to dryness, add 0.45g of anhydrous potassium carbonate and boric acid to grind at a mass ratio of 1:1 Melt the mixed flux at 860°C for 22 minutes in a muffle furnace, add 15 ml of 1:1 hydrochloric acid solution (the volume ratio of hydrochloric acid and water is 1:1), add an appropriate amount of ultrapure water during the dissolution process, and completely dissolve Afterwards, the volume was fixed in a 100ml volumetric flask with ultrapure water, and finally the aluminum content was measured by an inductively coupled plasma atomic emission spectrometer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com