Micro plate-type pulsating heat tube radiator capable of enhancing condensation

A technology of pulsating heat pipes and microplates, applied in indirect heat exchangers, cooling/ventilation/heating transformation, lighting and heating equipment, etc., can solve the problems of insufficient pulsation, small heat transfer area, and low sealing performance, and achieve pulsation Strong, increase heat transfer area, enhance the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

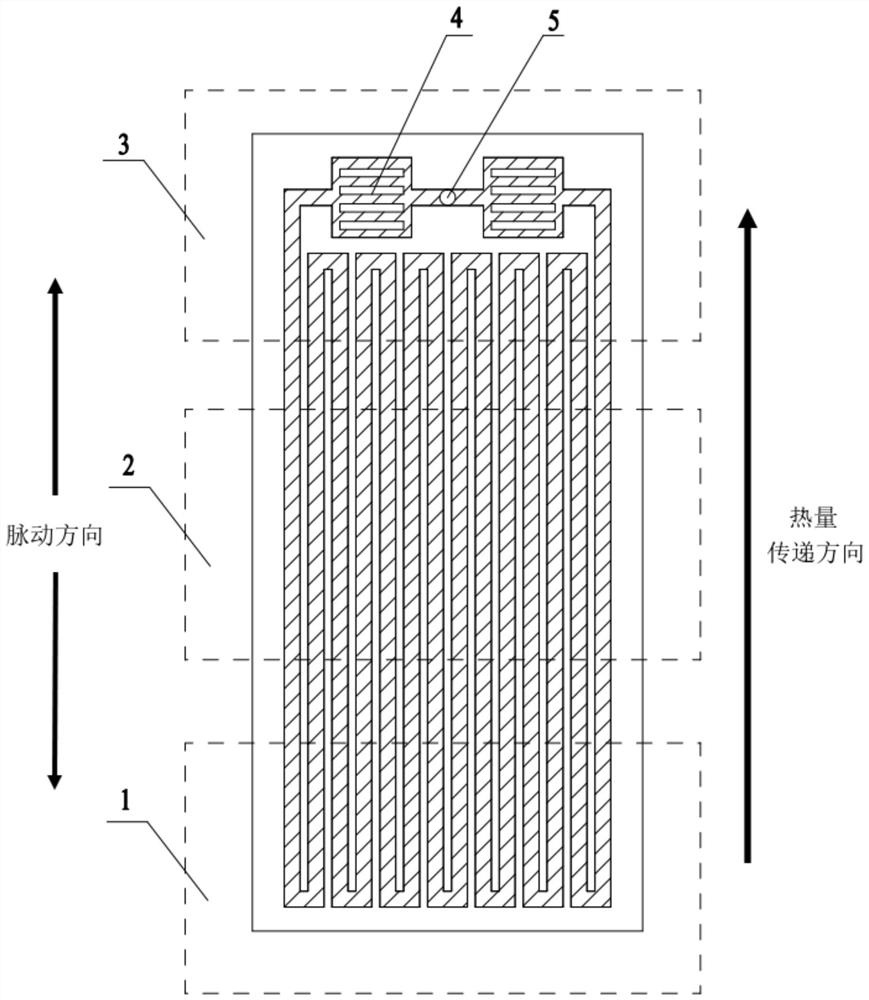

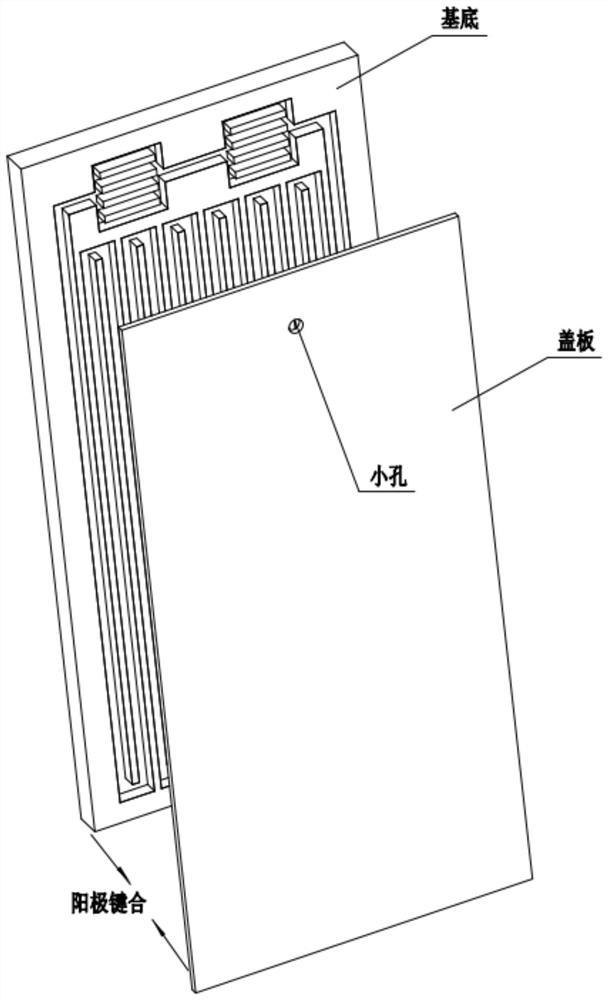

[0030] Such as figure 1 with figure 2 Shown: A micro-plate pulsating heat pipe radiator that can enhance heat transfer in the condensation section, which includes a silicon-based or copper-based plate, etched microchannels on the silicon-based or copper plate, and a glass or copper cover plate. The lower part of the micro-plate pulsating heat pipe is the evaporation section, the middle is the adiabatic section, and the upper part is the condensation section. The condensation section is divided into several bifurcated structures, which can increase the contact area between the fluid and the bottom plate and enhance heat transfer. There is a liquid filling port between the bifurcated structures. There are several bifurcated structures distributed in the condensation section, the micro channel is processed by MEMS etching, and the glass cover plate is sealed with the silicon base plate by anodic bonding. The cross-sectional shape of the micro channel can be square, rectangul...

Embodiment 2

[0032] Such as figure 1 , figure 2 with image 3 As shown, a micro-plate pulsating heat pipe that enhances condensation in the example of the present invention is mainly formed by bonding a silicon-based or copper substrate plate etched with micro-channels and glass or copper, including a condensation section 1, an adiabatic section 2, and an evaporation section 3 , bifurcation structure 4 and filling port 5. Vacuumizing and working medium injection are realized through the filling port 5 . In this example, the plate type pulsating heat pipe is filled with 50% volume fraction of pure water.

[0033] figure 1 The overall size of the micro-plate pulsating heat pipe is 49mm×100mm, the micro-channel aspect ratio is 1:1, both are 2mm, the interval between adjacent channels is 1mm, and there are 14 channels in the longitudinal direction. There are two bifurcated structures in the condensation section, such as image 3 with Figure 4 As shown, the area is 10mm×10mm, there a...

Embodiment 3

[0036] Such as figure 1 , figure 2 , image 3 As shown, the same as in Example 1, the difference is that the depth of the microchannel in the evaporation section and the heat insulation section is 3mm, the width is 2mm, and the aspect ratio is 1.5:1, and the depth of the bifurcated microchannel is 3mm, and the width is 1.2mm. The aspect ratio is 2.5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com