High-softness, high-toughness and cracking-resistant sheath material and preparation method thereof

A technology of sheath material and high toughness, applied in the field of high toughness and crack-resistant sheath material and its preparation, can solve the problems of sheath cracking and other problems, and achieve the effect of strong flexibility and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

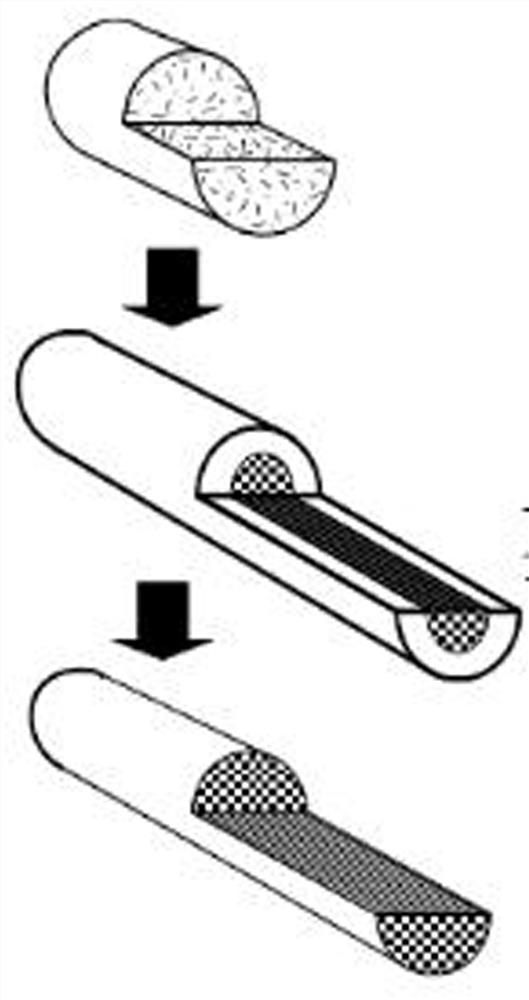

[0045] A wire cable resistant to cracking with high toughness sheathing material and preparation method, comprising the steps of:

[0046] The first step: the spiral crimp fiber

[0047] The elastic fiber of polyolefin entire tank heated by the heating cylinder to 115 deg.] C, and then through the fiber coil crimper, spiral crimped fibers were prepared, to prepare a helix angle of the spiral crimped fibers is 66 degrees, a pitch of 1 m;

[0048] Step Two: helical crimped fiber crosslinked

[0049] The first step in processing a helical crimped fiber good irradiation crosslinking, electron accelerator energy level by 3.0 MeV electron accelerator, the irradiation dose of 15 million electron de;

[0050] The third step: the helical crimped fiber stretched styling

[0051] The second step after spiral crimped fibers crosslinked by pre-heating the tank to 160. deg.] C, and then uniform stretching, straightening the spiral crimped fibers, then cooled rapidly to room temperature by cooli...

Embodiment 2

[0056] In the same embodiment, the difference is:

[0057] In the fourth step: The composition of the polyolefin melt is: 30 kg linear low density polyethylene, 30 kg of three-membered ethylene rubber, 3kg silicone rubber, 15kg magnesium hydroxide, 0.8kg antioxidant 1010 #, 0.8kg antioxidant 168 #, 2kg Polyethylene Wax, 0.5 kg of methylphenyl silicone oil, 3kg white oil, 2kg masterbatch.

Embodiment 3

[0059] In the same embodiment, the difference is:

[0060] In the fourth step: The composition of the polyolefin melt is: 25 kg linear low-density polyethylene, 25 kg of three yuan ethylene ethylene rubber, 2.5kg silicone rubber, 13kg magnesium hydroxide, 0.65 kg antioxidant 1010 #, 0.65 kg antioxidant 168 #, 1.5kg Polyethylene wax, 0.4 kg of methylphenylsilicone oil, 2.5kg of white oil, 1.5kg of masterbatch.

[0061] Example 1-3 Preparation of Sheath Material Performance Test Comparison (taken from finished cable care cover) as shown in Table 1.

[0062] Table 1 Example 1-3 Preparation Sheet Material Performance

[0063]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com