Method and device for loading high-speed flyer based on electrical explosion and laser coupling

An electric explosion and laser technology, applied in lasers, laser components, circuits, etc., can solve the problems of limited speed and limited energy of flyers, increase the speed of flyers, increase temperature and pressure, and increase the emission speed of flyers extreme effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

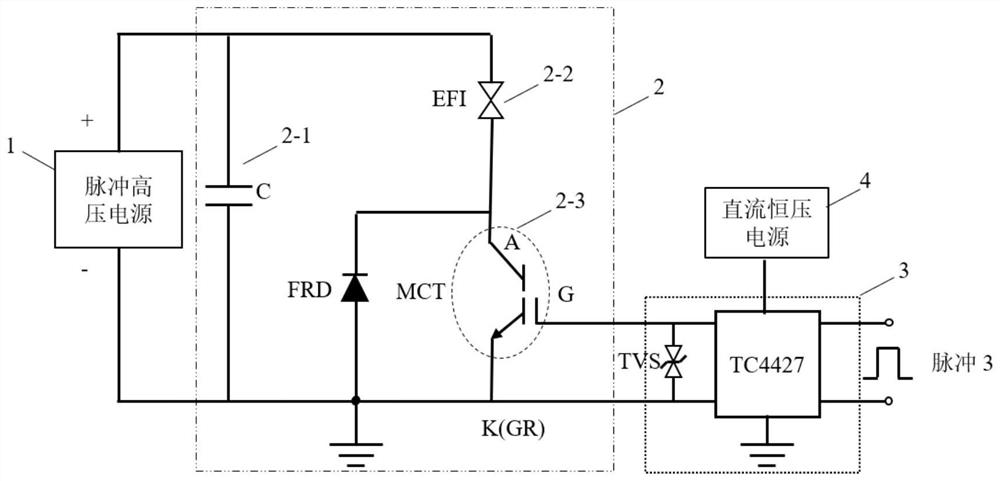

[0042] In this embodiment, a device for loading high-speed flyers based on electric explosion and laser coupling is designed. The flyer loading device includes a pulsed high-voltage power supply 1 , a capacitor discharge unit 2 , an MCT switch drive module 3 , a DC constant voltage power supply 4 , a solid-state pulsed laser 5 , an optical element 6 , and a digital delay generator 7 . The pulse high-voltage power supply 1 is used in this device to supply power to the capacitor discharge unit; the constant voltage DC source is used to supply power to the drive module of the MCT switch; the solid-state pulse laser is used to send laser beams with nanosecond pulse width; the digital delay generator is used to It is used to control the closure of the MCT switch and the laser to emit laser light.

[0043] The preparation steps of the device based on electric explosion and laser coupling loading high-speed flyer are as follows:

[0044] In the first step, the MEMS process is used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com