Capillary crystalline waterproof coating and waterproof coiled material composite waterproof system and construction method thereof

A technology of penetrating crystalline waterproofing and waterproofing membranes, which is applied in infrastructure engineering, building insulation materials, building materials, etc., can solve problems such as the inability to truly prevent water channeling, and achieve the elimination of side wall waterproofing, slipping, slipping, The effect of high compressive strength and firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

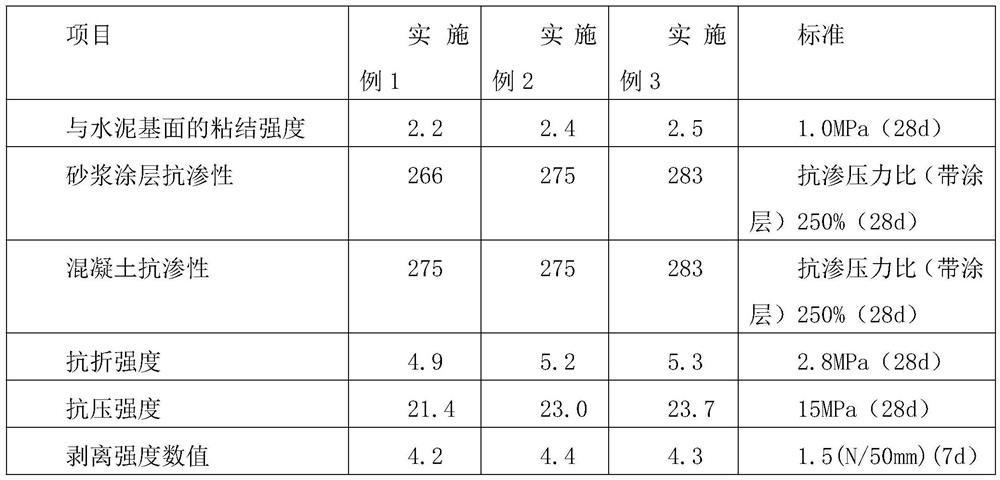

Examples

Embodiment 1

[0041] A construction method for a composite waterproof system of penetrating crystalline waterproof paint and waterproof coiled material, comprising the following steps:

[0042] Step a. clean up the base surface;

[0043] Step b. preparing a penetrating crystalline waterproof coating;

[0044] Step c. Stretch the thread on the base surface and determine the position where the waterproof membrane is laid;

[0045] Step d. Trial laying waterproof membrane;

[0046] Step e. Scratch coating the penetrating crystalline waterproof coating;

[0047] Step f. Composite paving and pasting the waterproof membrane on the waterproof coating;

[0048] Step g. hot-air welding at the overlapping edge of the coils;

[0049] Step h. Closing processing.

[0050] The polymer waterproof membrane in this embodiment is a thermoplastic polyolefin waterproof membrane. It can also be a high-density polyethylene self-adhesive film waterproof membrane.

[0051] In the step c, when elasticizing t...

Embodiment 2

[0066] A construction method for a composite waterproof system of penetrating crystalline waterproof paint and waterproof coiled material, comprising the following steps:

[0067] Step a. clean up the base surface;

[0068] Step b. preparing a penetrating crystalline waterproof coating;

[0069] Step c. Stretch the thread on the base surface and determine the position where the waterproof membrane is laid;

[0070] Step d. Trial laying waterproof membrane;

[0071] Step e. Scratch coating the penetrating crystalline waterproof coating;

[0072] Step f. Composite paving and pasting the waterproof membrane on the waterproof coating;

[0073] Step g. hot-air welding at the overlapping edge of the coils;

[0074] Step h. Closing processing.

[0075] The polymer waterproof membrane in this embodiment is a thermoplastic polyolefin waterproof membrane. It can also be a high-density polyethylene self-adhesive film waterproof membrane.

[0076] In the step c, when elasticizing t...

Embodiment 3

[0091] A construction method for a composite waterproof system of penetrating crystalline waterproof paint and waterproof coiled material, comprising the following steps:

[0092] Step a. clean up the base surface;

[0093] Step b. preparing a penetrating crystalline waterproof coating;

[0094] Step c. Stretch the thread on the base surface and determine the position where the waterproof membrane is laid;

[0095] Step d. Trial laying waterproof membrane;

[0096] Step e. Scratch coating the penetrating crystalline waterproof coating;

[0097] Step f. Composite paving and pasting the waterproof membrane on the waterproof coating;

[0098] Step g. hot-air welding at the overlapping edge of the coils;

[0099] Step h. Closing processing.

[0100] The polymer waterproof membrane in this embodiment is a thermoplastic polyolefin waterproof membrane. It can also be a high-density polyethylene self-adhesive film waterproof membrane.

[0101] In the step c, when elasticizing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com