Anticorrosive paint under thermal insulation layer, application of anticorrosive paint, coating process and anticorrosive coating

A coating process and coating technology, used in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of expanding the temperature range of coating coating and coating use temperature range, eliminating economic losses, reducing variety requirements, The effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

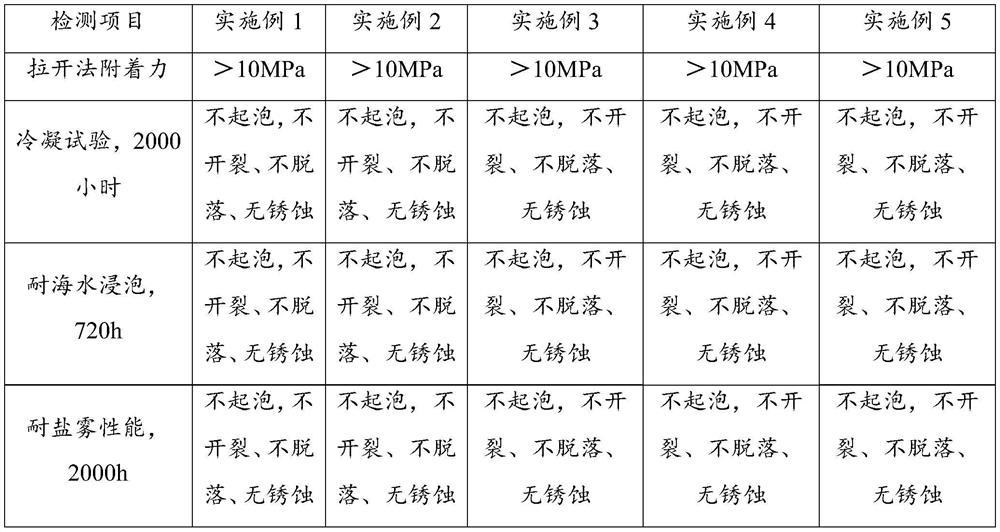

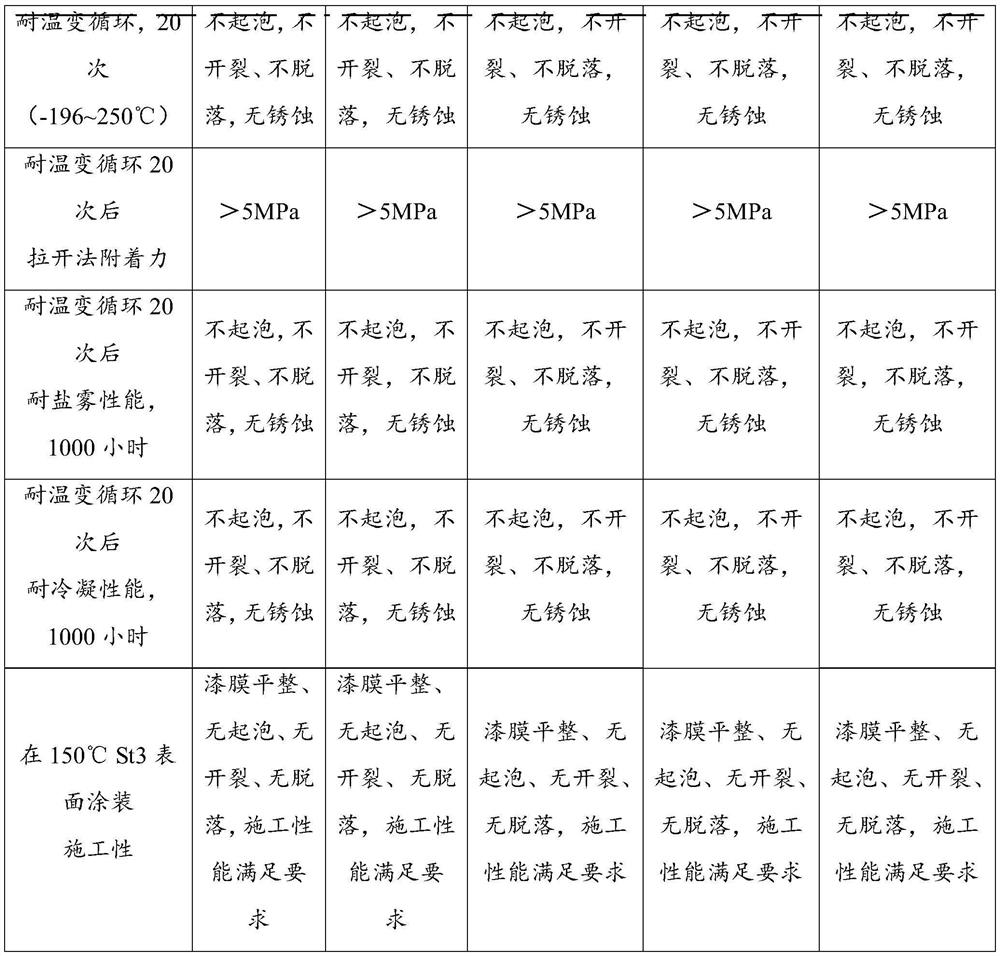

Examples

Embodiment 1

[0027] (1) Preparation of component A: 16 parts of phenol ketone epoxy resin, 4 parts of modified epoxy resin, 8 parts of bisphenol A novolac epoxy resin, 0.2 part of wetting and dispersing agent, 0.8 part of defoamer, thixotropic agent 0.5 parts, 20 parts of alumina, 30 parts of silicon carbide, 6 parts of non-leafing aluminum powder slurry, 2 parts of epoxy graphene slurry, 1 part of amino resin, mixed solvent (xylene: No. 1000 solvent: DBE: butanol =3:3:2:3.5) 11.5 parts.

[0028] (2) Preparation of component B: 76 parts of modified m-xylylenediamine, 21 parts of ketone solvent (isophorone: methyl isobutyl ketone = 4:10), 3 parts of KH-792 aminosilane adhesion .

[0029] (3) Mix component A and component B at a mass ratio of 6:1.

Embodiment 2

[0031] (1) Preparation of component A: 12 parts of phenol ketone epoxy resin, 5 parts of modified epoxy resin, 6 parts of bisphenol A novolac epoxy resin, 0.3 parts of wetting and dispersing agent, 0.6 parts of defoaming agent, thixotropic agent 0.6 parts, 16 parts of alumina, 28 parts of silicon carbide, 2 parts of non-leafing aluminum powder slurry, 12 parts of flake iron oxide, 1.5 parts of epoxy graphene slurry, 1.5 parts of amino resin, mixed solvent (xylene: 1000 No. solvent: DBE:butanol=4.5:3:3:4) 14.5 parts.

[0032] (2) Preparation of component B: 73 parts of styrene-modified m-xylylenediamine, 23.5 parts of ketone solvent (isophorone: methyl isobutyl ketone = 5:8), KH-792 aminosilane adhesion 3.5 servings.

[0033] (3) Mix components A and B with a mass ratio of 7:1.

Embodiment 3

[0035] (1) Preparation of component A: 10 parts of phenol ketone epoxy resin, 6 parts of modified epoxy resin, 4 parts of bisphenol A novolac epoxy resin, 0.4 part of wetting and dispersing agent, 0.4 part of defoaming agent, thixotropic agent 0.7 parts, 14 parts of aluminum oxide, 32 parts of silicon carbide, 14 parts of flake iron oxide, 1 part of epoxy graphene slurry, 2 parts of amino resin, mixed solvent (xylene: No. 1000 solvent: DBE: butanol=4.5 :3:3:5) 15.5 servings.

[0036] (2) Preparation of component B: 72 parts of styrene-modified m-xylylenediamine, 24 parts of ketone solvent (isophorone: methyl isobutyl ketone = 4:8), KH-792 aminosilane adhesion 4 parts.

[0037] (3) Mix component A and component B at a mass ratio of 8:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com