Preparation method of modified inorganic filler, modified inorganic filler and heat-conducting gel

An inorganic filler and modification technology, which is applied in the preparation of modified inorganic fillers, modified inorganic fillers and thermally conductive gels, can solve the problem of inability to carry out large-scale automatic pad operation, complex production process of over-thin gaskets, and volatile To achieve excellent lipophilic and hydrophobic properties, stable and healthy working temperature environment, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

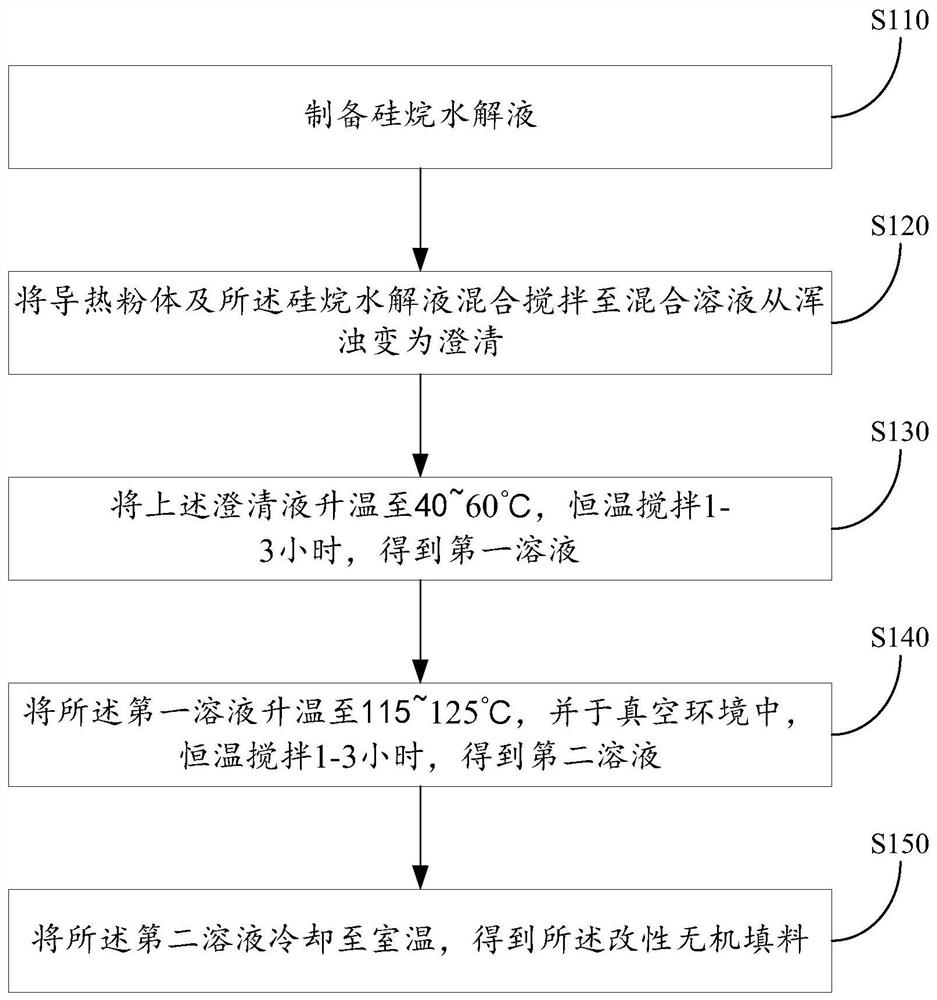

[0031] see figure 1 , a flow chart of the steps for the preparation method of the modified inorganic filler provided in the embodiment of the present invention, including the following steps:

[0032] Step S110: preparing a silane hydrolyzate.

[0033] In some of these embodiments, in the step of preparing the silane hydrolyzate, the following steps are specifically included:

[0034] The silane coupling agent, deionized pure water, and alcohol solvent are mixed and stirred for hydrolysis according to the mass fraction of (0.3-0.5%): (0.3-0.5%): (0.5-4.0%) to obtain a silane hydrolyzate.

[0035] In some of these embodiments, the silane coupling agent is selected from octyltrimethoxysilane, decyltrimethoxysilane, dodecyltrimethoxysilane, hexadecyltrimethoxysilane, octadecyltrimethoxysilane, at least one of alkyltrimethoxysilanes.

[0036] In some of these embodiments, the alcoholic solvent is anhydrous methanol or ethanol solvent.

[0037] Step S120: Mix and stir the therm...

Embodiment 1

[0048] (1) Preparation of silane coupling agent hydrolyzate required for powder modification:

[0049] Mix octyltrimethoxysilane coupling agent with deionized water and anhydrous methanol at a mass ratio of 1:1:3 at room temperature at a speed of 200 rpm for about 90 minutes, until the mixed solution changes from turbid to Change to clarified and ready to use.

[0050](2) Preparation of modified filler powder:

[0051] Add a certain amount of high-purity spherical aluminum powder to the planetary machine for stirring, and drop the prepared coupling agent hydrolyzate within 5 minutes. The amount used is that the mass of the coupling agent itself accounts for 0.5% of the mass of the high-purity spherical aluminum powder about. Heat up the temperature in the planetary machine to 50°C, and continue stirring for 1 hour after the temperature is stable; then raise the temperature to 120°C, turn on the vacuum after the temperature is stable, and continue stirring for 1 hour; finally...

Embodiment 2

[0053] (1) Preparation of silane coupling agent hydrolyzate required for powder modification:

[0054] Mix decanyltrimethoxysilane with deionized water and anhydrous methanol at a mass ratio of 1:1:3 at room temperature at a speed of 200 rpm for about 60 minutes, until the mixed solution changes from turbid to clear Ready to use.

[0055] (2) Preparation of modified filler powder:

[0056] Add a certain amount of high-purity spherical alumina to the planetary machine for stirring, and drop the prepared coupling agent hydrolyzate within 5 minutes. The amount used is that the mass of the coupling agent itself accounts for 0.5% of the mass of high-purity spherical alumina about. Heat up the temperature in the planetary machine to 50°C, and continue stirring for 1 hour after the temperature is stable; then raise the temperature to 120°C, turn on the vacuum after the temperature is stable, and continue stirring for 1 hour; finally, cool to room temperature, take out the pot and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com