Method for cooperatively treating low-concentration organic wastewater through adsorption and in-situ light regeneration

A technology for organic wastewater and collaborative treatment, which is applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, light water/sewage treatment, etc., can solve the problems of inability to exert fast kinetics of adsorption, and has good prospects for industrial application, but is not easy Effects of shedding and effective reuse of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

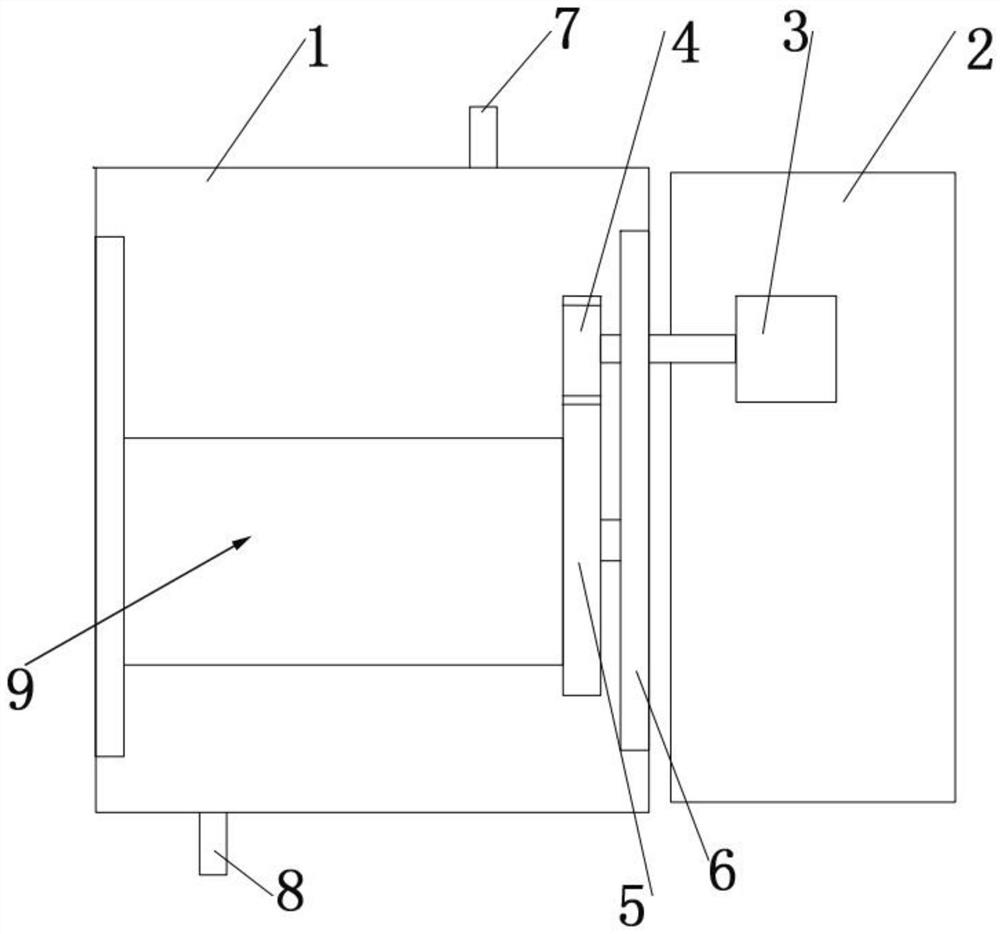

Image

Examples

Embodiment 1

[0045] The synthesis of two-dimensional sheet-like carbon nanosheets, the steps are as follows: 1.0 mmol pyridine-2,6-dicarbaldehyde, 2.0 mmol 1,4-diamidoxime benzene and 4.0 mmol cesium carbonate were mixed thoroughly, and 10.0 mL dimethyl sulfoxide and 0.5 mL of deionized water, stirred for 2 h to form a homogeneous solution, then transferred to a 20 mL reaction kettle, heated to 100 °C, and kept for 12 h. Subsequently, it was separated by centrifugation, washed with dilute HCl (concentration of dilute HCl solution was 5%), acetone and tetrahydrofuran for further separation and purification, and dried in a vacuum oven at 60 °C for 24 h to obtain two-dimensional sheet-like COFs. Finally, transfer the powder to a tube furnace, raise the temperature to 800 °C at 5 °C / min in an argon atmosphere and keep it for 2 h to obtain two-dimensional sheet-like carbon nanosheets (characterized by BET, the two-dimensional sheet-like carbon nanosheets The specific surface area of carbon na...

Embodiment 2

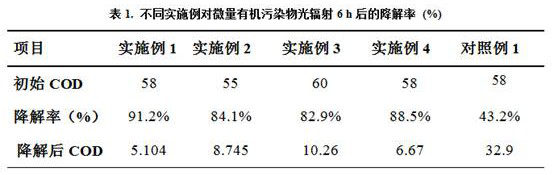

[0056] The experimental process was repeated in Example 1, the only difference being that "in Example 1, 10 L of ethylene glycol aqueous solution (with a COD concentration of 58) at a concentration of 45 mg / L was replaced with 10 L of ethylene glycol with a concentration of 25 mg / L Benzophenone solution (COD concentration is 55)", all the other conditions are the same as in Example 1. After 6 hours of wastewater treatment, the solution in the circulating pool was sampled, and the concentration of benzophenone in the solution was detected by high performance liquid chromatography. The experimental results are summarized in Table 1.

Embodiment 3

[0058] The experimental process was repeated in Example 1, the only difference being that "in Example 1, 10 L of ethylene glycol aqueous solution (with a COD concentration of 58) at a concentration of 45 mg / L was replaced with 10 L of ethylene glycol with a concentration of 25 mg / L Benzaldehyde solution (COD concentration is 60)", all the other conditions are the same as in Example 1. After 6 hours of wastewater treatment, the solution in the circulating pool was sampled, and the concentration of benzaldehyde in the solution was detected by high performance liquid chromatography. The experimental results are summarized in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com