Obeticholic acid pharmaceutical composition as well as preparation method and application thereof

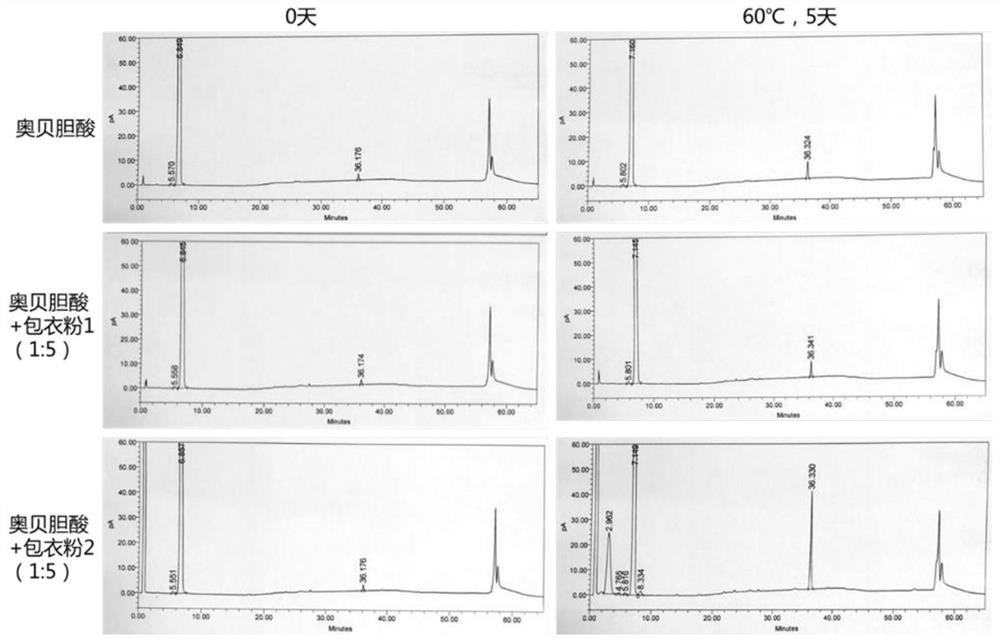

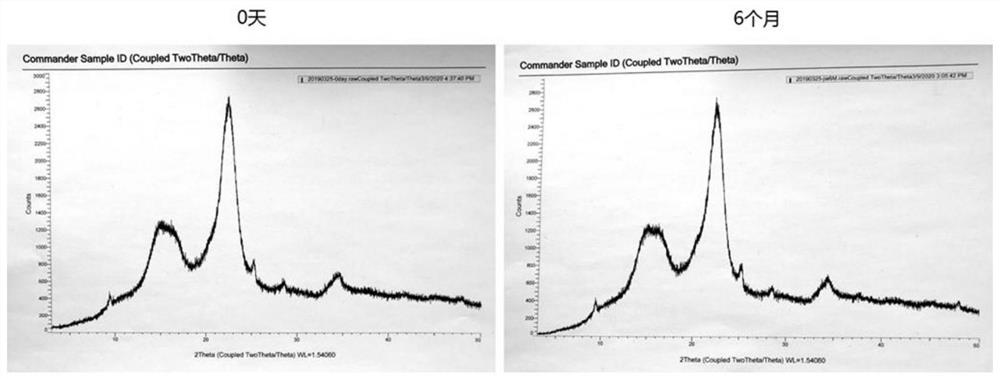

A technology of obeticholic acid and its composition, which is applied in the field of obeticholic acid pharmaceutical composition and its preparation, can solve the problems of unfavorable large-scale industrial production, unstable preparation process, and low production efficiency, and achieve optimal dissolution rate and Uniformity of quality, shortened production cycle, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

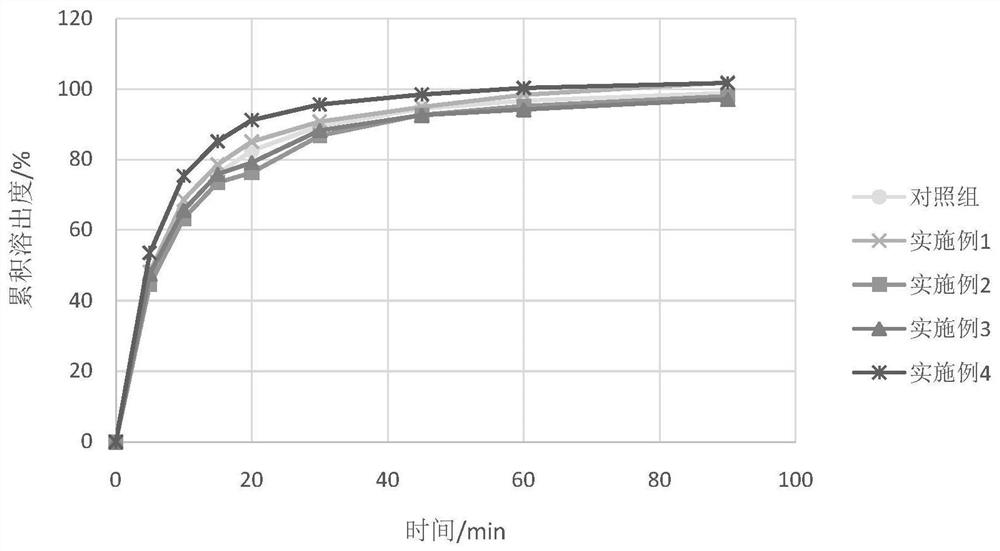

Embodiment 1

[0108] Embodiment 1 Preparation of obeticholic acid pharmaceutical composition of the present invention

[0109] The preparation method of obeticholic acid pharmaceutical composition comprises the following steps:

[0110] (1) sending the obeticholic acid crude drug into an ultra-high-speed jet mill for micronization, with a pressure of 0.3Mpa;

[0111] (2) Put obeticholic acid micronized granules, microcrystalline cellulose in granules, and sodium carboxymethyl starch in granules into a ziplock bag and mix for 5 minutes, pass through a vertical granulator equipped with a 1.0mm screen, and then transfer to After mixing in a ziplock bag for 8 minutes, add intragranular magnesium stearate, and mix for 5 minutes to prepare a premix;

[0112] Put the prepared premix into the dry granulator, set the feeding speed: 20rpm, the roller pressure: 25bar, the roller speed: 8rpm, the shear speed: 100rpm, the granulation speed: 100rpm, the screen aperture: 1.0 mm, run with the above par...

Embodiment 2

[0115] Embodiment 2 Preparation of obeticholic acid pharmaceutical composition of the present invention

[0116] The preparation method of obeticholic acid pharmaceutical composition comprises the following steps:

[0117] (1) Send the obeticholic acid crude drug into a jet mill for micronization, with a pressure of 0.5Mpa;

[0118] (2) Put obeticholic acid micronized granules, intragranular microcrystalline cellulose, and intragranular sodium carboxymethyl starch into a 5L mixing hopper, mix at 30rpm for 25min, and pass through a vertical granulator equipped with a 1.2mm screen. , then transferred to the mixing hopper and mixed at the same speed for 10 minutes, then added intragranular magnesium stearate, and mixed for 8 minutes to obtain a premix;

[0119] Put the prepared premix into the dry granulator, set the feeding speed: 20rpm, the roller pressure: 40bar, the roller speed: 8rpm, the shear speed: 100rpm, the granulation speed: 100rpm, the screen aperture: 1.5 mm, ru...

Embodiment 3

[0122] Embodiment 3 Preparation of obeticholic acid pharmaceutical composition of the present invention

[0123] The preparation method of obeticholic acid pharmaceutical composition comprises the following steps:

[0124] (1) Send the obeticholic acid crude drug into a jet mill for micronization, with a pressure of 0.6Mpa;

[0125] (2) Put obeticholic acid micronized granules, microcrystalline cellulose in granules, and sodium carboxymethyl starch in granules into a 50L mixing hopper for mixing, mix at a speed of 25rpm for 60min, and then pass through a vertical mixer equipped with a 1.5mm sieve. The granulator and the granulator are also equipped with rounded granulation knives, set the speed at 300rpm, and then transfer the undersieve to a 50L mixing hopper, and mix at a speed of 45rpm; after 30min, add magnesium stearate in the granule and mix for 20min. Get the premix;

[0126] Put the prepared premix into the dry granulator, set the feeding speed: 60rpm, the roller p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com