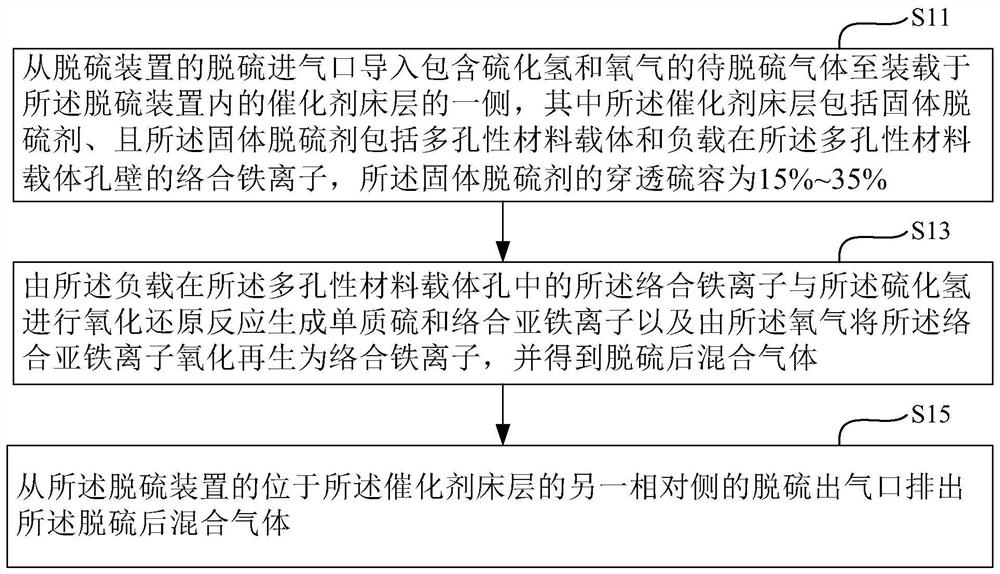

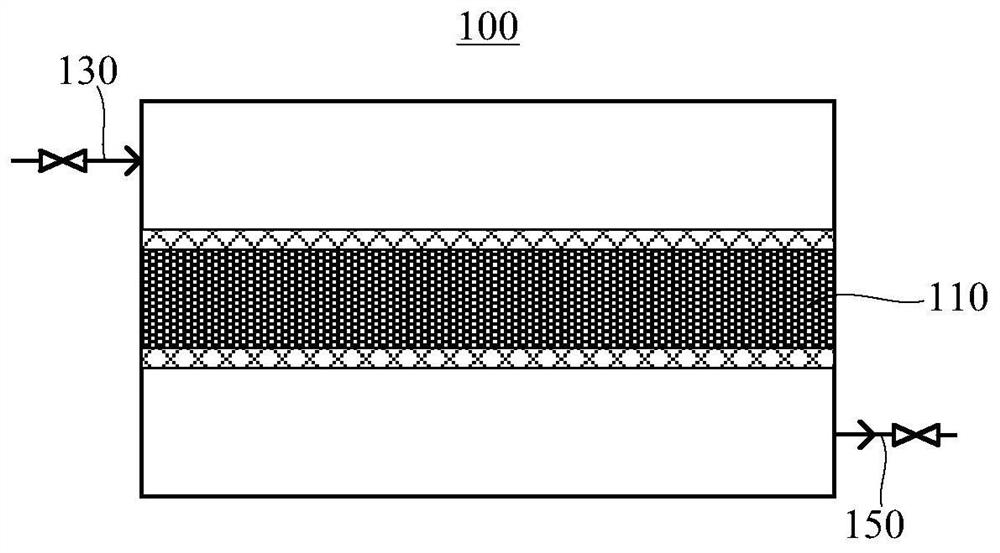

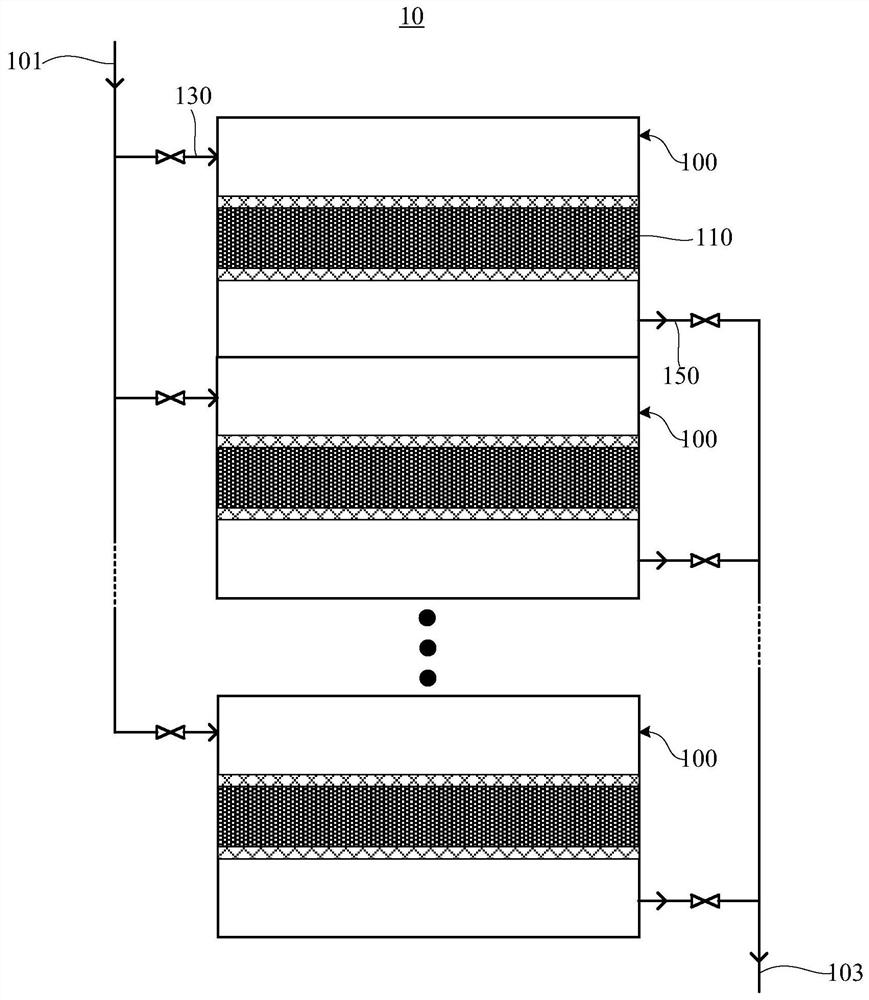

Desulfurization method, device and system

A technology of desulfurization device and desulfurizer, which is applied in the field of desulfurization system, can solve the problems of polluted environment and low desulfurization efficiency, and achieve the effects of wide application, convenient treatment and avoiding difficult wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Taking activated carbon as an example of a porous material carrier, the preparation method of the solid desulfurizer according to the embodiment of the present invention includes the following steps:

[0048] (a) take by weighing the iron source that contains sulfate radical, stabilizer and organic complexing agent and dissolve in water to obtain lysate, stir lysate and constantly add pH adjusting agent in lysate during stirring, to make complexed iron solution ;

[0049] (b) Activated carbon and complexed iron solution are placed in a sugar coating machine or a double-cone rotary macerating machine to roll, so that the complexed iron solution is absorbed by activated carbon to obtain loaded activated carbon; and

[0050] (c) Take out the loaded activated carbon and put it into a sealed bag and dry the loaded activated carbon to obtain a solid desulfurizing agent.

[0051]Wherein, the activated carbon and the complex iron solution are placed in a sugar coating machine ...

example 1

[0055] First, prepare 1000L (liter) complex iron ion concentration of 0.03mol / L (mole per liter) complex iron solution, specifically: weigh 6.7Kg (kg) of sorbitol, 24Kg of disodium EDTA and ferrous sulfate Dissolve 10Kg in 1000L deionized water to form a solution, stir the solution for 12 hours, make the internal raw materials fully contact and oxidize ferrous ions, add sodium carbonate to the solution continuously during the stirring period to adjust the pH value of the solution, and make the complex iron solution The final pH value of the solution was 9.2, and a deep red solution was obtained, namely complex iron solution.

[0056] Then, take by weighing 100Kg and the gac of 60% water absorption rate, it is poured into sugar-coating machine, and to gac spraying or the complex iron solution (0.03mol / L) that soaks 60Kg above-mentioned preparations, control sugar-coating machine to turn and roll 10 ~ After 30 minutes, all the complex iron solution is completely absorbed by the ...

example 2

[0058] First, prepare 1000L of complexed iron solution with a complexed iron ion concentration of 0.03mol / L, specifically: weigh 6.7Kg of sorbitol, 24Kg of disodium EDTA and 15.1Kg of ferrous ammonium sulfate in 1000L of deionized water, stir Dissolve the solution for 12 hours to fully contact the internal raw materials and oxidize ferrous ions. During the stirring period, add sodium carbonate to the solution to adjust the pH value of the solution, so that the final pH value of the complex iron solution is 9.2, and the deep red solution is obtained. Complex iron solution.

[0059] Then, take by weighing 100Kg and the gac of 60% water absorption rate, it is poured into sugar-coating machine, and to gac spraying or the complex iron solution (0.03mol / L) that soaks 60Kg above-mentioned preparations, control sugar-coating machine to turn and roll 10 ~ After 30 minutes, all the complex iron solution is completely absorbed by the activated carbon to obtain loaded activated carbon, ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com