A rust removal device for steel bars for construction

A technology for construction and steel bars, which is applied in the direction of grinding drive device, abrasive surface adjustment device, grinding/polishing safety device, etc. It can solve the problems of high labor intensity, easy omission, and influence on construction quality and progress, so as to improve grinding Effect, effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

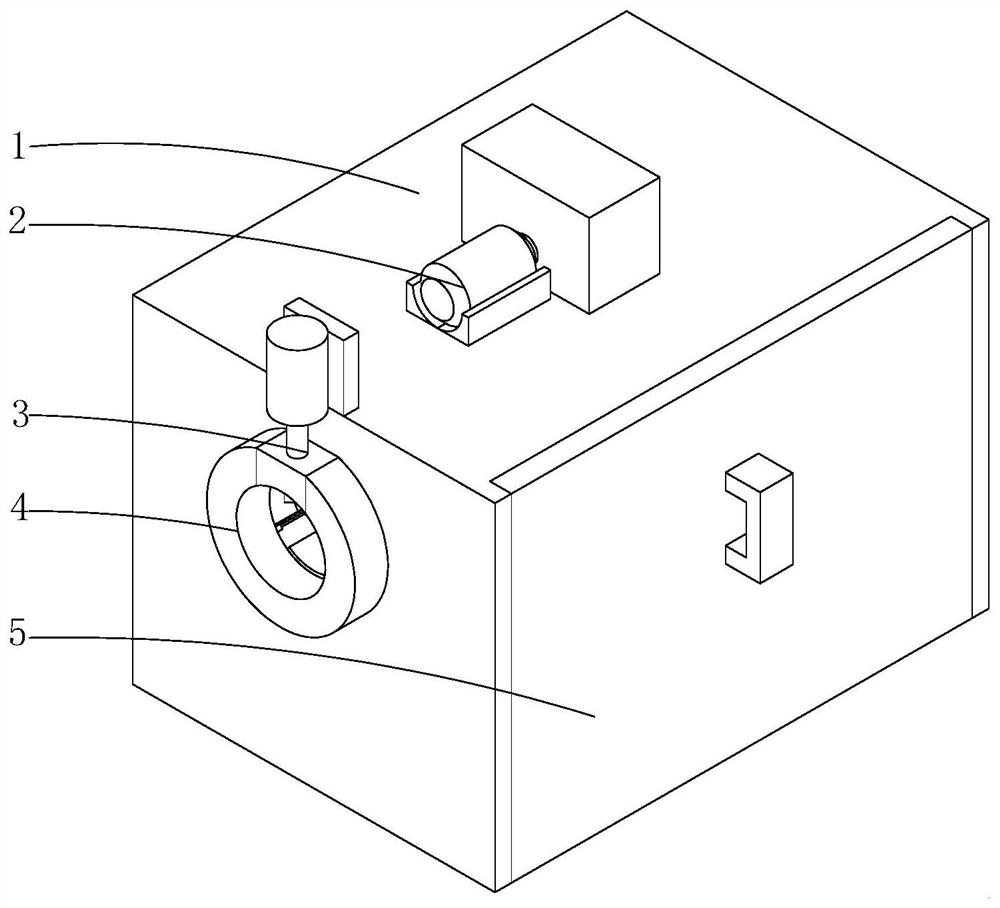

[0028] see Figure 1-9 , the present invention provides a technical solution: a rust removal device for steel bars for construction, comprising a device main body 1, a motor 2 is fixed on the top of the device main body 1, the output shaft of the motor 2 extends to the inside of the device main body 1, and the output of the motor 2 A pinion 6 is fixed on the top of the shaft, a fixing ring 4 is fixed on the left side of the device main body 1, a hydraulic driving device 3 for fixing the steel bars is arranged on the top of the fixing ring 4, and the front surface of the device main body 1 penetrates and slides for collecting. A collection b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com