Preparation method and application of BiOCl nano photocatalyst with high visible light catalytic activity

A catalytic activity, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low visible light catalytic activity, complex preparation process, and high safety hazards, and achieve good light. The effect of catalytic degradation efficiency, simple preparation process and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of a BiOCl nano photocatalyst with high visible light catalytic activity, comprising the steps of:

[0033] S1. Dissolve a certain amount of polyethylene glycol in deionized water, then add water-soluble bismuth salt or its hydrate, and stir thoroughly;

[0034] S2, adding a certain amount of water-soluble chloride salt into the above solution, fully stirring at room temperature;

[0035] S3, separating the generated precipitate, washing and drying to obtain BiOCl nano photocatalyst powder.

[0036] Preferably, in S1, the molecular weight of polyethylene glycol is 200-10000.

[0037] Preferably, in S1, the water-soluble bismuth salt is bismuth nitrate pentahydrate Bi(NO 3 ) 3 "5H 2 O or bismuth chloride.

[0038] Preferably, the stirring in S1 is stirring at room temperature for 30-60 min.

[0039] Preferably, in S1, the molar ratio of polyethylene glycol to bismuth nitrate pentahydrate is 0.01-4:1, specifically, when the molecular weight of pol...

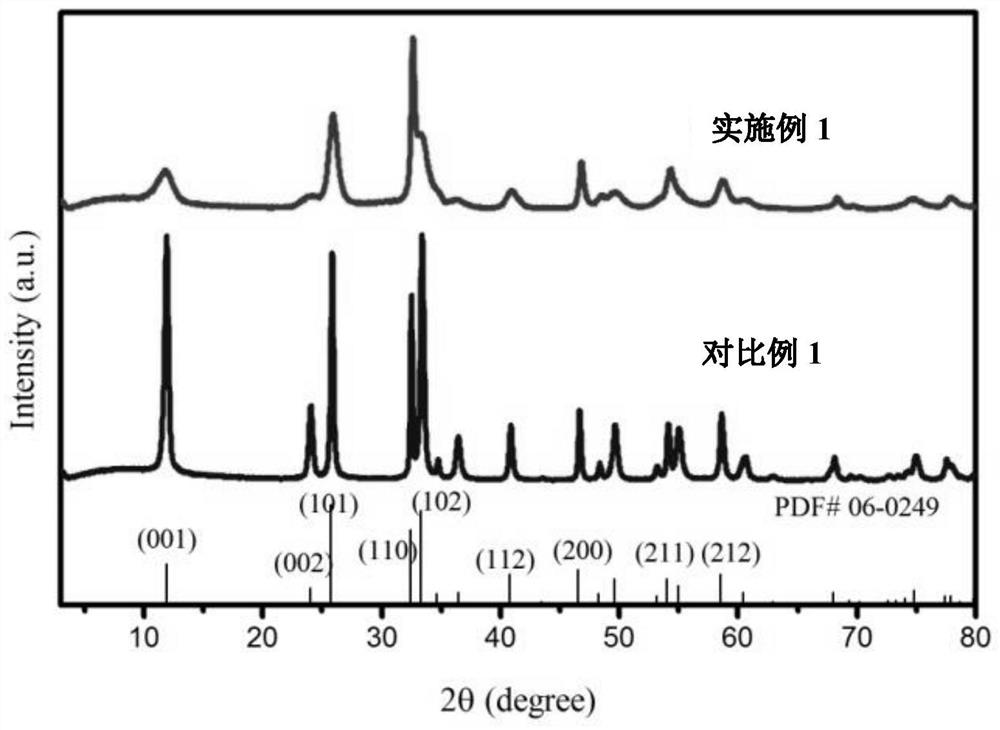

Embodiment 1

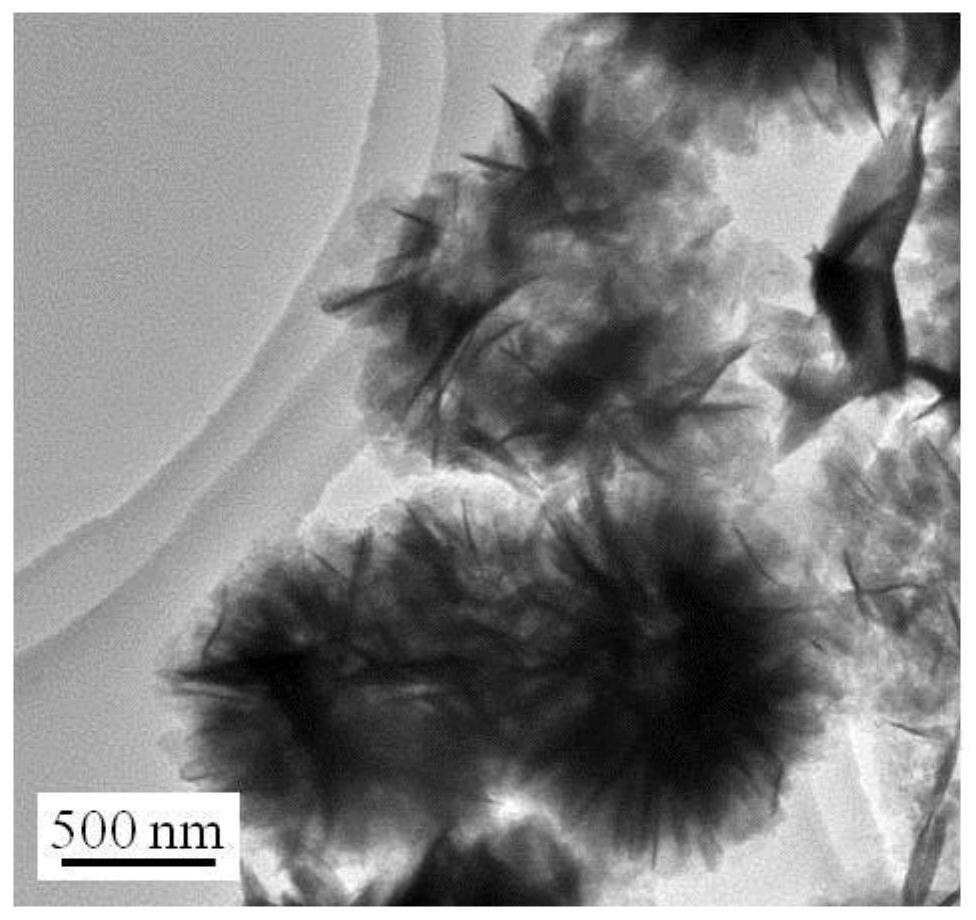

[0056] Dissolve 1 mmol of polyethylene glycol 2000 in 40 mL of deionized water, then add 2 mmol of bismuth nitrate pentahydrate, stir at room temperature for 30 min, add 2 mmol of potassium chloride, and stir for 40 min. The precipitate was separated by centrifugation, washed with deionized water until neutral, and dried in a vacuum oven at 40°C for 12 hours to obtain BiOCl powder.

[0057] The research on the photocatalytic performance of the sample prepared in Example 1 shows that after dark adsorption for 60 min, the adsorption degradation rate is 54%, and then irradiated with an LED lamp (32W), the degradation rate is 98% in 10 min, and 100% in 15 min.

Embodiment 2

[0067] Dissolve 0.1 mmol of polyethylene glycol 2000 in 40 mL of deionized water, then add 1 mmol of bismuth nitrate pentahydrate, stir at room temperature for 30 min, add 1 mmol of potassium chloride, and stir for 40 min. The precipitate was separated by centrifugation, washed with deionized water until neutral, and dried in a vacuum oven at 40°C for 12 hours to obtain BiOCl powder.

[0068] The research on the photocatalytic performance of the sample prepared in Example 2 shows that after dark adsorption for 60min, the adsorption degradation rate is 40%, and then irradiated with an LED lamp (32W), the degradation rate is 74% in 10min, 81% in 15min, and 81% in 20min. The rate is 92%.

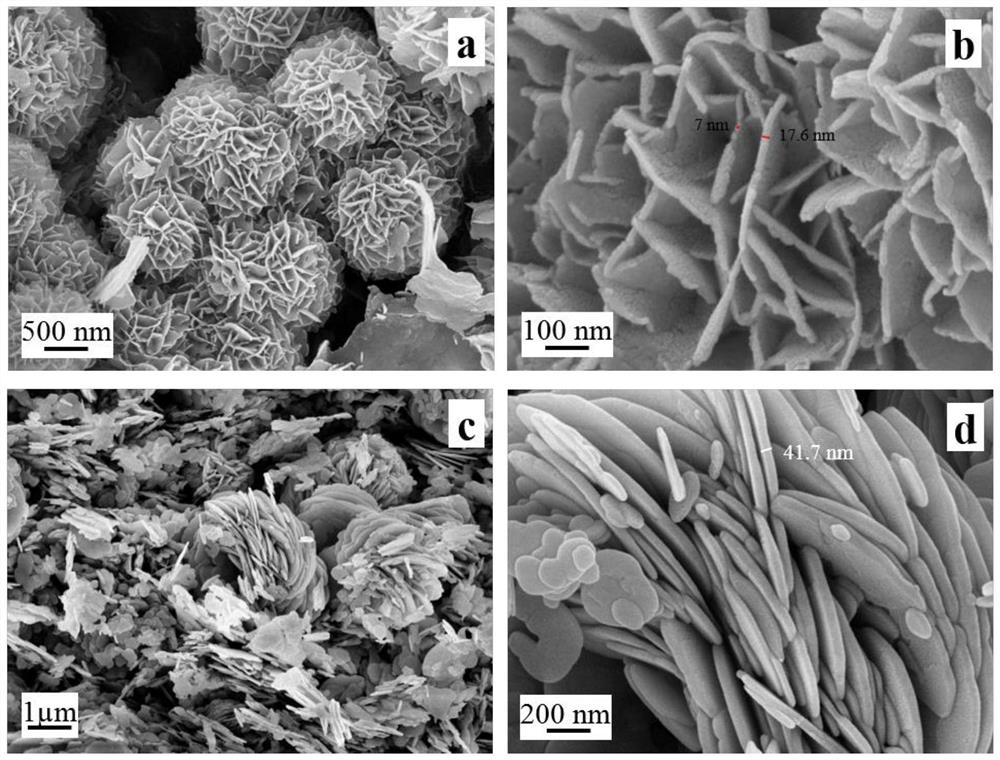

[0069] Adopt the scanning electron microscope to carry out the microscopic morphology characterization of embodiment 2 sample, as Figure 4 as shown in a. It can be seen that the BiOCl sample prepared in Example 2 mainly presents the morphology of nanosheets, the dispersion of nanosheets is g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com