Laser diode

A laser diode and tube cap technology, applied in the laser field, can solve the problems of affecting the quality of the spot, large beam loss, and small divergence angle, etc., and achieve the effects of high conversion efficiency, high collimation, and small radius of curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

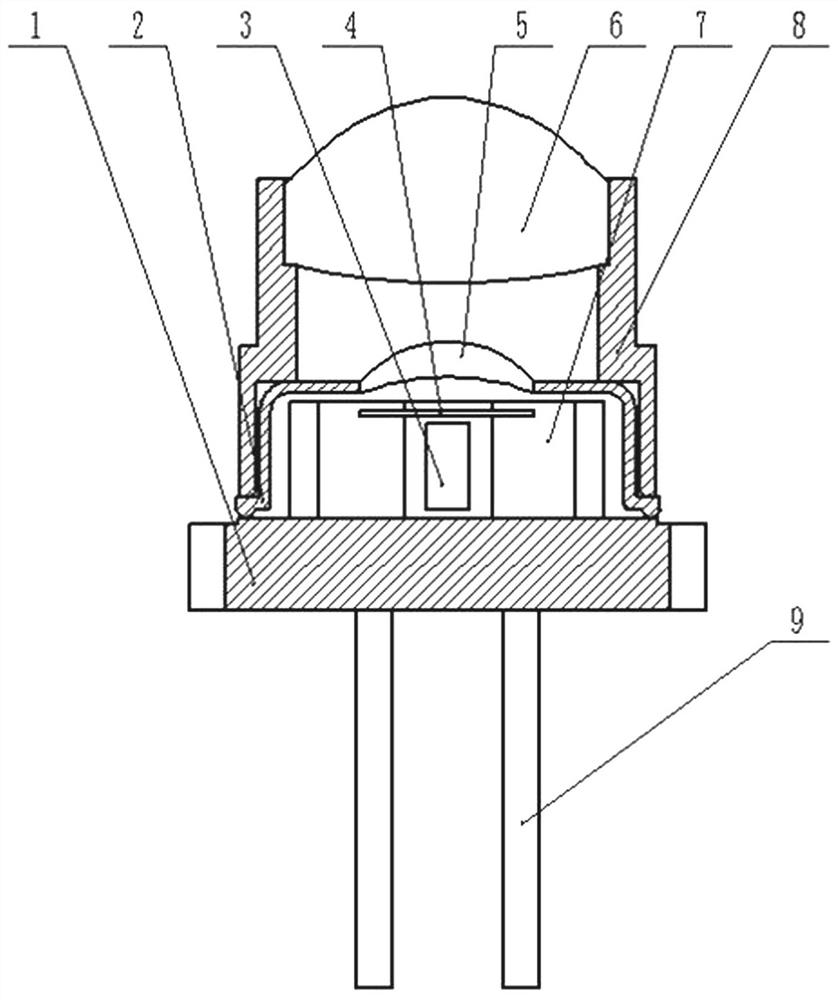

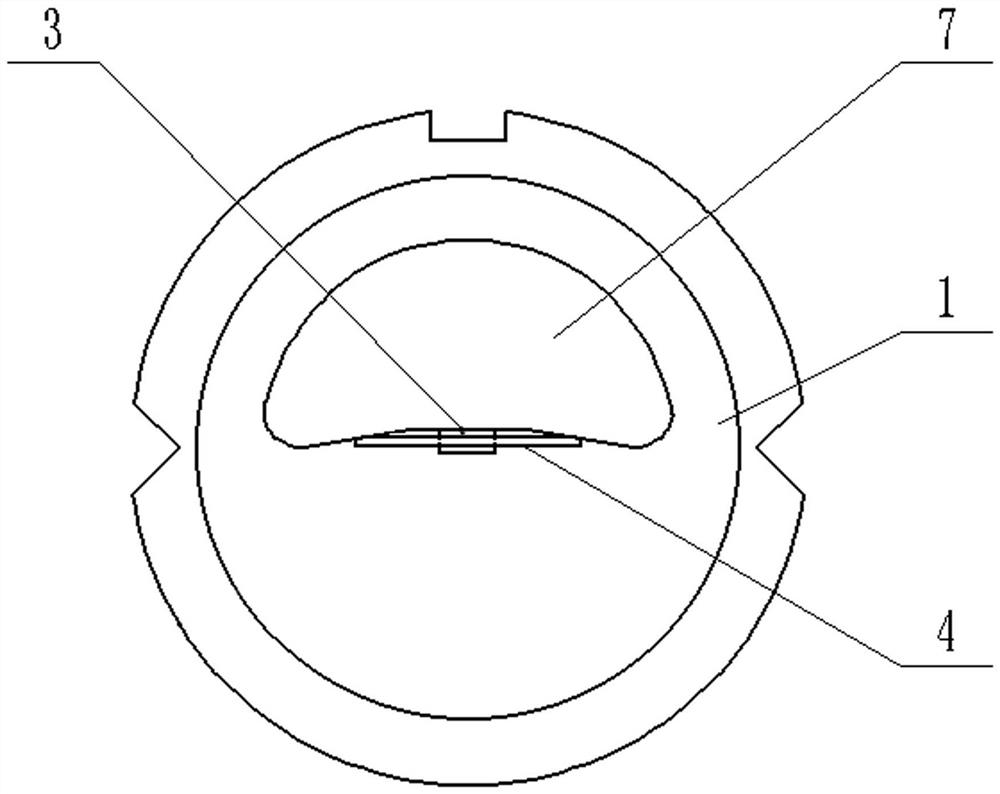

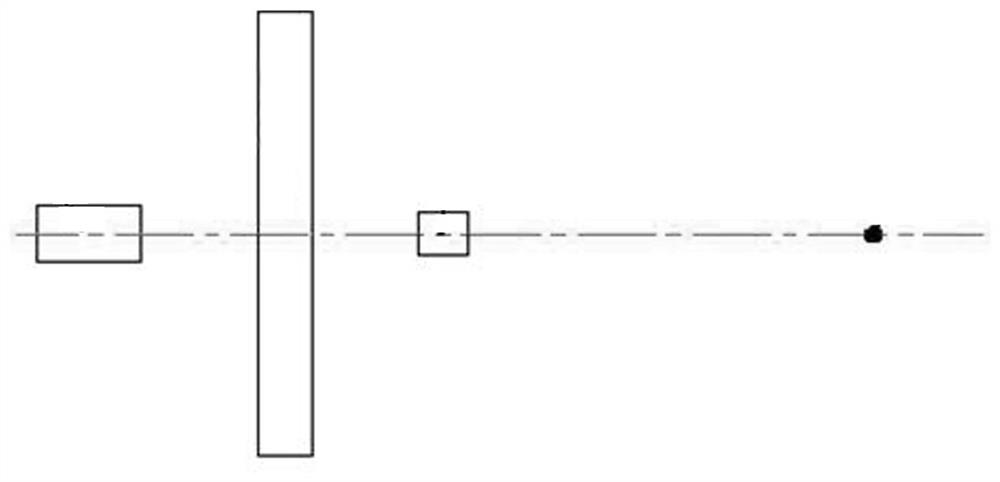

[0011] Such as figure 1 with figure 2 A laser diode, comprising a tube base 1, a tube cap 2, a chip 3 and a radiator 7 for dissipating heat to the chip 3, the tube cap 2 is provided with a hole, and a light-transmitting mirror is fixedly installed in the hole, and also includes a tube fixedly installed on the Inside the tube cap 2 (it is well known to those skilled in the art that if it is fixedly installed in the tube cap 2, the two ends of the bare fiber 4 can be directly or indirectly fixed to the heat sink 7 to achieve fixed installation) and located between the chip 3 and the light-transmitting mirror Bare fiber 4 (the optical fiber has a core, cladding, and coating layer from the inside to the outside in sequence. Those skilled in the art know that the bare fiber 4 is an optical fiber with the coating removed), the axial direction of the bare fiber 4 and the light emission of the chip 3 The direction is vertical, and the light-transmitting mirror is a meniscus-shaped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com