Chromium oxide/carbon fluoride/high conductive material composite material for lithium primary battery

A chromium oxide, high conductivity technology, used in battery electrodes, active material electrodes, non-aqueous electrolyte batteries, etc., can solve problems such as chromium oxide sensitivity, uneven coating of composite materials, and limited improvement in material conductivity. , to achieve the effect of improving conductivity, improving discharge specific capacity and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

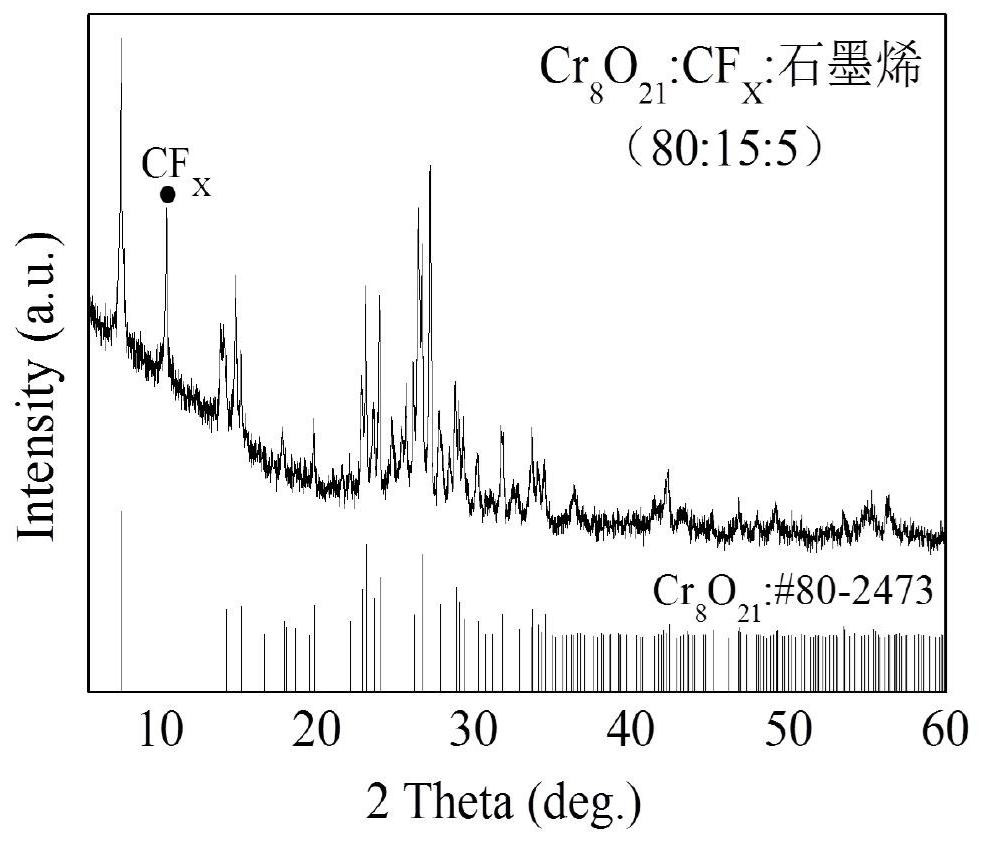

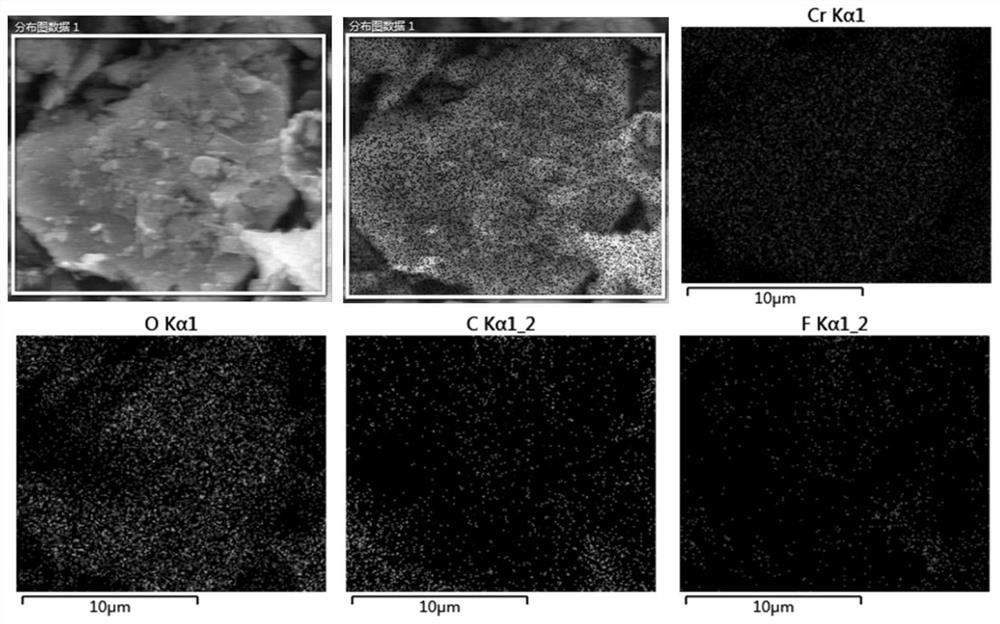

[0039] A kind of Cr for lithium primary battery 8 O 21 The preparation method of carbon fluoride / graphene composite material, comprising the following steps:

[0040] ① Preparation of doping material: after mixing carbon fluoride, graphene and water, ultrasonically dispersing for 30 minutes, and then drying until the water is completely removed, that is, a uniformly mixed doping material is obtained;

[0041] ②According to CrO 3 : The mass ratio of carbon fluoride:graphene=80:15:5, the chromium trioxide and the doping material are ball-milled for 6h under the condition of rotating speed 300r / min, so that the material is uniformly dispersed;

[0042] ③Place the product obtained in step ② in a tube furnace, sinter it with oxygen at 270°C for 48h, take it out and grind it into powder, pass through a 200-mesh sieve, and obtain Cr 8 O 21 / carbon fluoride / graphene composite material; the oxygen flow rate is 25ml / min;

[0043] ④ The composite material, SuperP, CNTS, and PVDF ...

Embodiment 2

[0046] A kind of Cr for lithium primary battery 8 O 21 The preparation method of carbon fluoride / graphene composite material, comprising the following steps:

[0047] ① Preparation of doping material: after mixing carbon fluoride, graphene and water, ultrasonically dispersing for 30 minutes, and then drying until the water is completely removed, that is, a uniformly mixed doping material is obtained;

[0048] ②According to CrO 3 : The mass ratio of carbon fluoride: graphene = 85:10:5, the chromium trioxide and the doping material are ball-milled for 6h under the condition of rotating speed 300r / min, so that the material is uniformly dispersed;

[0049] ③Place the product obtained in step ② in a tube furnace, sinter it with oxygen at 270°C for 48h, take it out and grind it into powder, pass through a 200-mesh sieve, and obtain Cr 8 O 21 / Fluorocarbon / graphene composite material; the oxygen flow rate is 25ml / min.

Embodiment 3

[0051] A kind of Cr for lithium primary battery 8 O 21 The preparation method of carbon fluoride / graphene composite material, comprising the following steps:

[0052] ① Preparation of doping material: after mixing carbon fluoride, graphene and water, ultrasonically dispersing for 30 minutes, and then drying until the water is completely removed, that is, a uniformly mixed doping material is obtained;

[0053] ②According to CrO 3 : The mass ratio of carbon fluoride:graphene=75:20:5, the chromium trioxide and the doping material are ball-milled for 6h under the condition of rotating speed 300r / min, so that the material is uniformly dispersed;

[0054] ③Place the product obtained in step ② in a tube furnace, sinter it with oxygen at 270°C for 48h, take it out and grind it into powder, pass through a 200-mesh sieve, and obtain Cr 8 O 21 / Fluorocarbon / graphene composite material; the oxygen flow rate is 25ml / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com