Preparation and application of oil-water amphiphilic titanium-based Ag/TiO2@PANI photocatalyst

A photocatalyst and amphiphilic technology, applied in the field of photocatalysis, can solve the problems of low adsorption of organic waste gas and low photocatalytic efficiency, and achieve the effects of improving the utilization rate of solar energy, simple production method and increasing lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

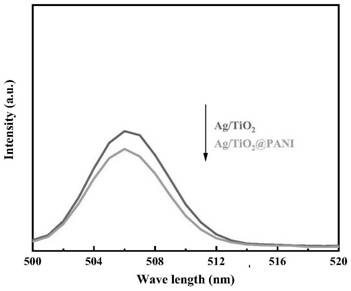

[0025] Embodiment 1 Preparation of oil-water amphiphilic titanium-based photocatalyst

[0026] At room temperature, weigh 20mmolAgNO 3 (3.4g) was dissolved in 200mL water, and 1mol (79.9g) of TiO with a particle size of 25nm was added 2 (Model: P25), and then stirred by a magnetic stirrer at 600rpm for 30min to obtain a white suspension, then pour the white suspension into a high-pressure reaction kettle, put it into an oven, and conduct hydrothermal crystallization at 160°C for 24h, the obtained reaction Suction filtration, the filter cake was washed with deionized water and absolute ethanol, then placed in a vacuum oven, and dried in vacuum at 80°C for 12h to obtain Ag / TiO 2 Photocatalyst; weigh 0.1g ammonium persulfate and 20g Ag / TiO 2 Mix evenly by mechanical stirring, then add 100uL aniline (the density is 1.02g / cm under standard conditions, about 102mg) and stir rapidly. After 30min of reaction, grind to obtain powder (to facilitate subsequent tests and disperse in the...

Embodiment 2

[0031] Example 2 Photocatalytic degradation of toluene 1 by oil-water amphiphilic titanium-based photocatalyst

[0032] Add 200ml of pure water into the photocatalytic reactor, then put in a 4W 365nm ultraviolet lamp, seal the device, start stirring, and feed 500ppm of toluene-air mixture while turning on the ultraviolet lamp, and connect the reaction tail gas to the gas chromatograph. Determine the initial toluene concentration in the tail gas. Add 0.1 g Ag / TiO to the photocatalytic reactor 2 @PANI and 200ml of pure water, then put in a 4W UV lamp, seal the device, start stirring, and feed 500ppm of toluene-air mixture while turning on the UV lamp, connect the reaction tail gas to a gas chromatograph, and measure the toluene in the tail gas concentration.

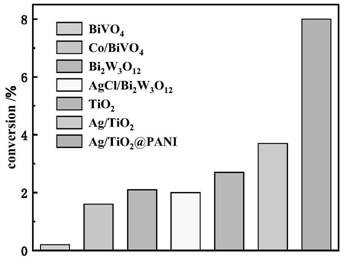

[0033] The experimental results show that at room temperature, the space velocity is 100000ml h -1 g -1 , catalyst feed 0.1g, water 80mL, 4W365nm ultraviolet light source, and under the conditions of 500ppm toluene, th...

Embodiment 3

[0034] Example 3 Photocatalytic degradation of toluene 2 by oil-water amphiphilic titanium-based photocatalyst

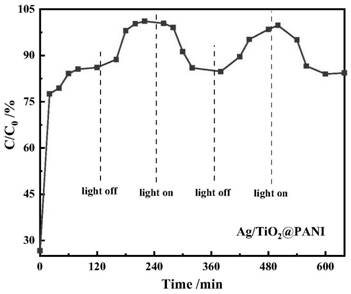

[0035] Add 370ml of pure water into the photocatalytic reactor, then put in a 100W high-pressure mercury lamp, seal the device, start stirring, and feed 1000ppm of toluene-air mixture while turning on the high-pressure mercury lamp, and connect the reaction tail gas to the gas chromatograph , to determine the initial toluene concentration in the tail gas. Add 0.1 g Ag / TiO to the photocatalytic reactor 2 @PANI and 370ml of pure water, then put in a 100W high-pressure mercury lamp, seal the device, start stirring, and feed 1000ppm of toluene-air mixture while turning on the high-pressure mercury lamp. The reaction tail gas was connected to a gas chromatograph to measure the concentration of toluene in the tail gas.

[0036] The experimental results show that at room temperature, the space velocity is 100000ml h -1 g -1 , under the conditions of feeding 0.1g of cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com