Method for producing l-lactic acid by using distilled grains

A technology of liquor and waste residues, which is applied in the field of advanced processing and fermentation of agricultural and sideline products to prepare L-lactic acid, can solve the problems of low efficiency of enzymatic hydrolysis of liquor and high cost of reuse of liquor waste residues, so as to improve selection adaptability, increase energy consumption, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

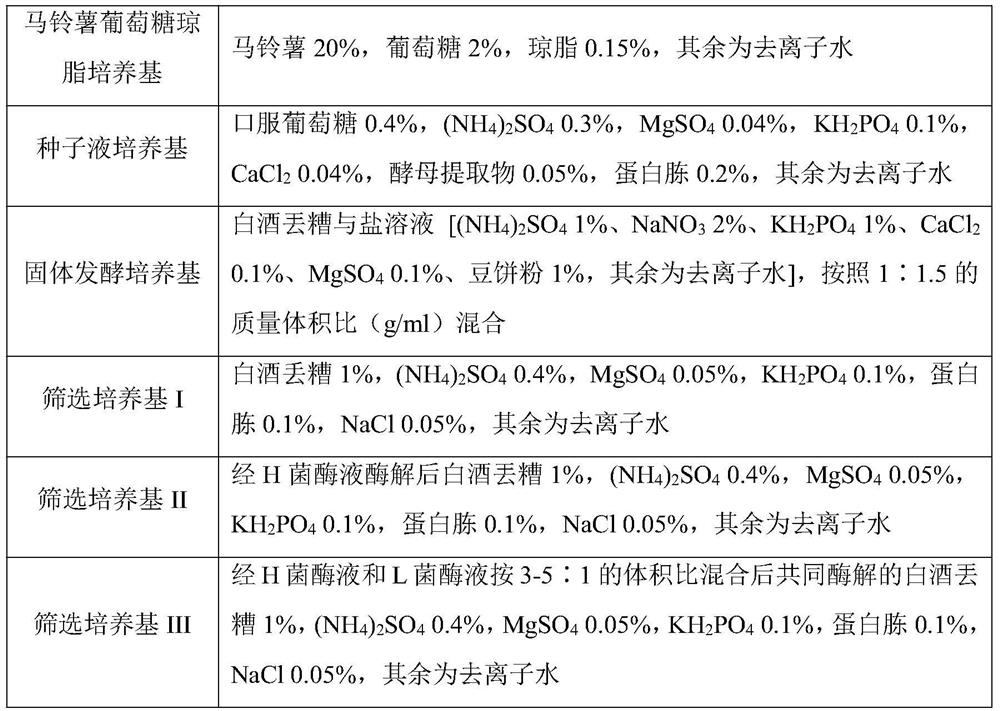

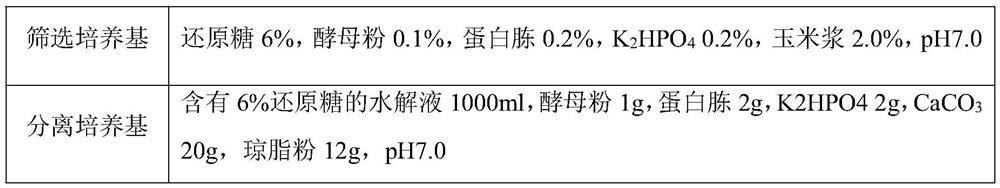

[0049] The preparation method of the above-mentioned mixed bacteria enzyme liquid, comprises the following steps:

[0050] a. Take samples from pit mud, discarded grains, and the surrounding soil of the winery, screen and enrich the screening medium with liquor discarded grains as the carbon source, and obtain bacterial samples after separation and purification; after the bacterial samples are activated, use The solid fermentation medium is fermented and cultivated, and the inoculum of the activated bacteria sample is 9-11% of the solid fermentation medium, then it is leached, suction filtered, and centrifuged to obtain bacterial enzyme liquid A, which is used for liquor The enzymatic hydrolysis of the discarded grains is screened to obtain H bacteria, and the H bacteria enzyme liquid is obtained by fermentation, and the enzyme activity of the H bacteria enzyme liquid is 5.0-5.8IU / ml;

[0051] b. Take samples from pit mud, discarded grains, and the surrounding soil of the wine...

Embodiment 1

[0088] A. Mix the discarded grains of liquor with tap water according to a solid-to-liquid ratio of 1:3 g / ml, soak for 4 hours, wet pulverize the infiltrated discarded grains to 200 mesh, and filter to obtain the crushed discarded grains;

[0089] B. PEG-8000 is mixed with mixed bacterial enzyme solution (H bacterial enzyme solution: L bacterial enzyme solution: M bacterial enzyme solution is 16: 3: 1) at a ratio of 0.004: 1 g / ml to obtain a mixed solution;

[0090] C. Mix the pulverized and discarded grains obtained in step A and the mixed solution obtained in step B according to the ratio of 1:10g / ml, at 50°C, under the condition of 140rpm, constant temperature vibration for 72h enzymolysis, suction filtration to obtain the initial sugar solution, at 50°C The initial sugar solution was evaporated under reduced pressure to a reducing sugar concentration of 60 g / L to obtain a concentrated sugar solution;

[0091] D. Adjust the pH of the concentrated sugar solution to 6.5 with ...

Embodiment 2

[0094] A. Mix the discarded grains of liquor with tap water according to a solid-to-liquid ratio of 1:3 g / ml, soak for 4 hours, wet the infiltrated grains of grains to 250 mesh, and filter to obtain crushed grains of grains;

[0095] B. PEG-8000 is mixed with mixed bacterial enzyme solution (H bacterial enzyme solution: L bacterial enzyme solution: M bacterial enzyme solution is 15: 4: 1) at a ratio of 0.005: 1 g / ml to obtain a mixed solution;

[0096] C. The pulverized and discarded grains obtained in step A are mixed with the mixed solution obtained in step B according to the ratio of 1:10g / ml, at 50°C, under the condition of 140rpm, constant temperature vibration for 72h enzymolysis, suction filtration to obtain primary sugar liquid, at 52°C The initial sugar solution was evaporated under reduced pressure to a reducing sugar concentration of 65 g / L to obtain a concentrated sugar solution;

[0097] D. Adjust the pH of the concentrated sugar solution to 6.5 with CaO, then add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com