Lightweight broadband electromagnetic shielding coating and preparation method thereof

An electromagnetic shielding coating and electromagnetic shielding technology, applied in conductive coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor dispersion uniformity of absorbents or conductive powders, limit the development of electromagnetic shielding coatings, and reduce the practicability of materials. Achieve the effects of improving mechanical and physical properties, improving electromagnetic shielding efficiency, and reducing surface density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

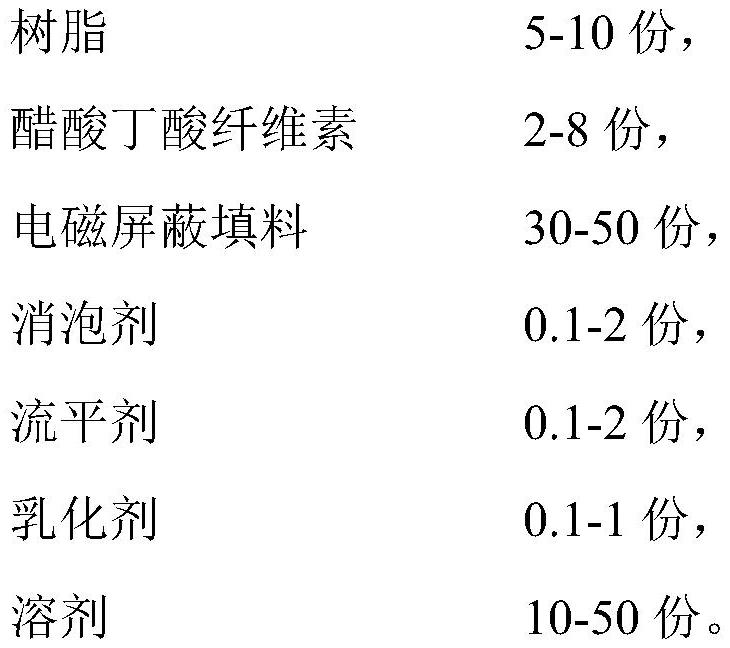

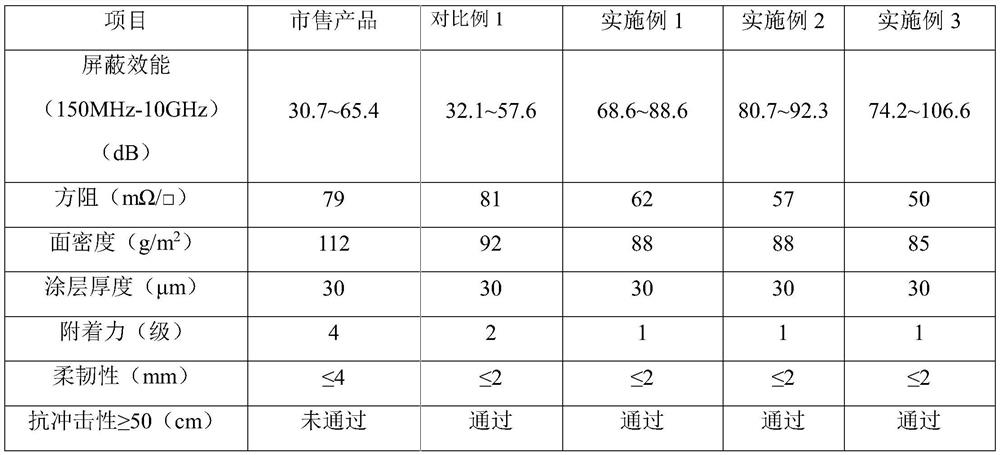

[0029] A light broadband electromagnetic shielding coating, comprising the following materials: 10 parts of polyurethane modified epoxy resin, 2 parts of cellulose acetate butyrate, 30 parts of electromagnetic shielding filler (2.73 parts of PS microspheres, 13.64 parts of silver powder, silver-coated copper powder 13.64 parts), DREWPLUS L-1311 (defoamer) 0.2 parts, dimethylsiloxane (leveling agent) 0.3 parts, YJ-16-3 (emulsifier) 1 part, ethyl acetate / PMA mixed solvent (volume ratio 1:1) 56.5 parts.

[0030] The preparation process is as follows: (1) Add polyurethane modified epoxy resin, DREWPLUS L-1311, dimethyl siloxane and ethyl acetate / PMA mixed solvent into the mixing kettle, and stir for 30 minutes at a stirring speed of 500 rpm , mix evenly to obtain mixture a; (2) then slowly add PS microspheres, silver powder, silver-coated copper powder and YJ-16-3 to mixture a in sequence, then adjust the speed to 500 rpm and stir for 20 minutes to obtain a uniform (3) Filter t...

Embodiment 2

[0032] A light broadband electromagnetic shielding coating, comprising the following materials: 10 parts of polyurethane modified epoxy resin, 2 parts of cellulose acetate butyrate, 50 parts of electromagnetic shielding filler (wherein 4.55 parts of PS microspheres, 22.73 parts of silver powder, silver-coated copper powder 22.73 parts), DREWPLUS L-1311 (defoamer) 0.2 parts, dimethylsiloxane (leveling agent) 0.3 parts, YJ-16-3 (emulsifier) 0.1 parts, ethyl acetate / PMA mixed solvent (volume fraction 1:1) 37.4 parts.

[0033] The preparation process is as follows: (1) Add polyurethane modified epoxy resin, DREWPLUS L-1311, dimethyl siloxane and ethyl acetate / PMA mixed solvent into the mixing kettle, and stir for 30 minutes at a stirring speed of 500 rpm , mix evenly to obtain the first mixture; (2) then slowly add PS microspheres, silver powder, silver-coated copper powder and YJ-16-3 to the first mixture, then adjust the rotating speed to 600 rpm, and stir for 25 minutes, Obt...

Embodiment 3

[0035] A light-weight broadband electromagnetic shielding coating, comprising the following materials: 5 parts of polyurethane modified epoxy resin, 2 parts of cellulose acetate butyrate, 48.4 parts of electromagnetic shielding filler (wherein 4.4 parts of PS microspheres, 22 parts of silver powder, silver-coated copper powder 22 parts), DREWPLUSL-1311 (defoamer) 0.2 parts, dimethylsiloxane (leveling agent) 0.3 parts, YJ-18-MS (emulsifier) 0.5 parts, ethyl acetate / PMA mixed solvent ( Volume fraction 1:1) 43.6 parts.

[0036] The preparation process is as follows: (1) Add polyurethane modified epoxy resin, DREWPLUS L-1311, dimethyl siloxane and ethyl acetate / PMA mixed solvent into the mixing kettle, and stir for 30 minutes at a stirring speed of 500 rpm , mix well to obtain the second mixture; (2) then slowly add PS microspheres, silver powder, silver-coated copper powder and YJ-18-MS to the first mixture, then adjust the rotating speed to 600 rpm, and stir for 25 minutes, O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com