Assembly type inorganic keel, assembly type partition and installation method thereof

An installation method and assembled technology, applied to walls, buildings, building components, etc., can solve the problems of cost, high transportation cost, and easy cracks, etc., and achieve shrinkage probability reduction, simple material components, and simple manufacturing methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

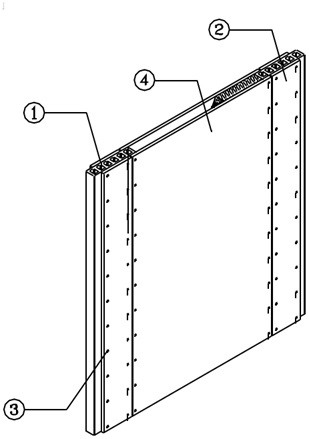

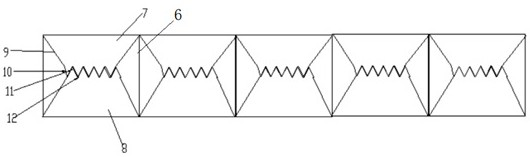

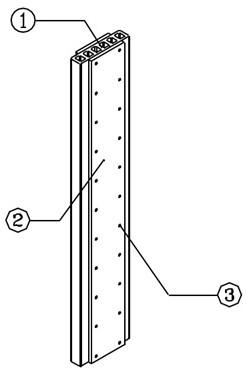

[0198] In order to achieve the above object, the technical solution adopted by the present invention is: an assembled inorganic keel, such as figure 1 and figure 2 As shown, it includes a layer of square tubular inorganic keel vertical plate 1, two inorganic keel reinforced cover plates 2 are clamped on both sides of the square tubular inorganic keel vertical plate 1 in the thickness direction, square tubular inorganic material vertical plate 1 and two inorganic keel The reinforced cover plate 2 is superimposed on the center line and assembled and fixed by the connector 3. The square tubular inorganic keel vertical plate 1 is a hollow tube with horizontal and vertical support components inside. The horizontal and vertical support components are multiple parallel and spaced apart. support board. Both ends of the square tubular inorganic keel vertical plate 1 in the width direction are longer than the inorganic keel reinforced cover plate 2 and extend to the inside of the asse...

Embodiment 2

[0220] Embodiment 2: An assembled partition (planar type), which is assembled by using the assembled inorganic keel of the application. The installation method of the spliced partition of the assembled inorganic keel includes the following steps: (1), draw the partition positioning line; (2), determine the positioning line of the inorganic keel vertical plate 1; (3), install the square tubular inorganic keel vertical plate 1 ; (4), fix the square tubular inorganic keel vertical plate 1 with corner codes or wedges, and cement; (5), take the position of the center line of the square tubular inorganic keel vertical plate 1 as the standard, install the inorganic keel reinforced cover plate 2 to form a double (6) Between two adjacent inorganic keels and on the staggered platform of the combined inorganic keel, one side partition panel of the assembled partition is installed sequentially 4, sound-absorbing cotton or thermal insulation cotton (or leave it blank) and partition panel...

Embodiment 3

[0222] Example 3: Assembled "I"-shaped inorganic keel assembly partition; the assembled inorganic keel includes two inorganic keel reinforced cover plates and one inorganic keel vertical plate. An inorganic keel vertical plate is vertically arranged at the center line between two adjacent inorganic keel reinforced cover plates, and is connected into one body through connectors to form an "I"-shaped assembled inorganic keel. The two sides of the inorganic keel reinforced cover plate are compounded with fiber reinforced material, and the two sides of the inorganic keel vertical plate are compounded with fiber reinforced material.

[0223] The installation procedure is as follows: (1), draw the partition positioning line; (2), determine the positioning line of the assembled inorganic keel, (3) draw the center line of the inorganic keel reinforced cover plate 2; (4) put two adjacent inorganic keels in parallel An inorganic keel vertical plate 1 between the reinforced cover plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com