Preparation method of end plate of battery module for new energy vehicle, battery module and end plate

A technology for battery modules and new energy vehicles, applied in battery pack components, circuits, motor vehicles, etc., can solve problems such as cracking, explosive holes, and inability to meet cell expansion force conditions, and overcome low mechanical properties. , the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

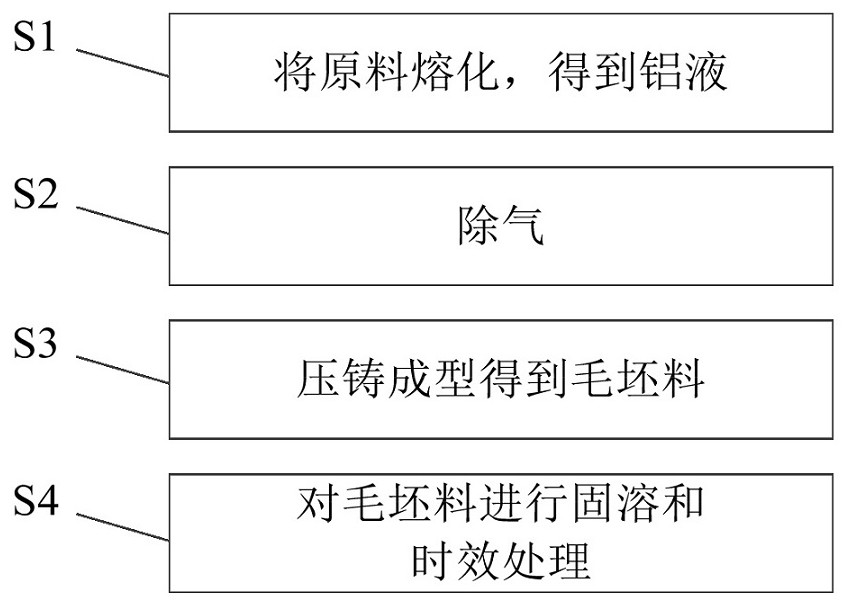

[0036] In order to solve the above technical problems, the present invention provides a method for preparing an end plate of a battery module for a new energy vehicle, comprising:

[0037] S1: melting the raw materials to obtain liquid aluminum;

[0038] S2: Degassing;

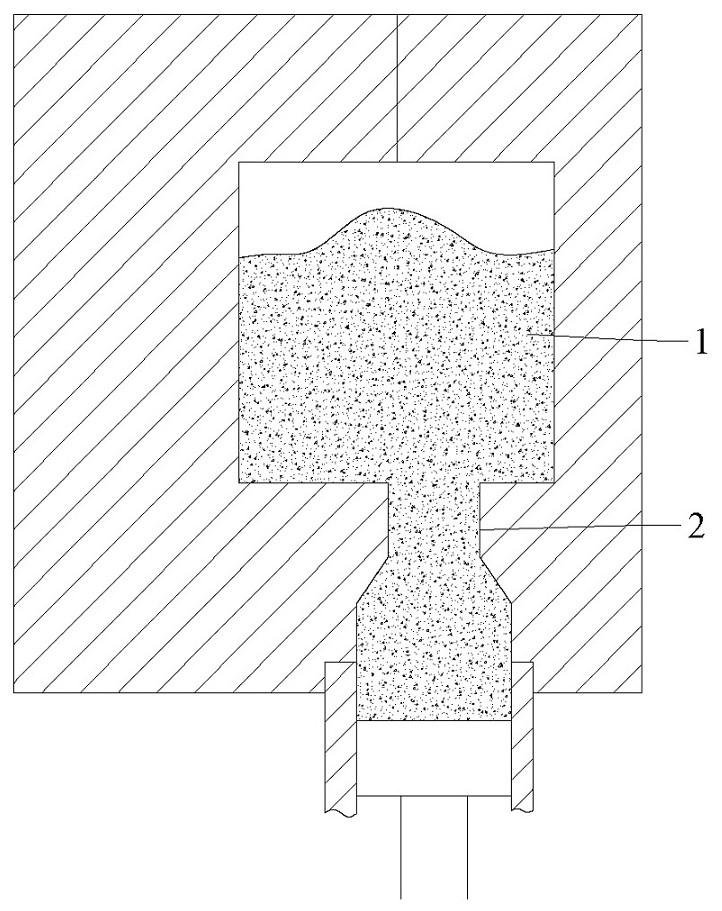

[0039] S3: Die-casting to obtain blanks;

[0040] S4: Solid solution and aging treatment are performed on the blank.

[0041] In step S1, optionally, the raw materials may include aluminum ingots and returned materials; the weight percentage of the returned materials in the raw materials is ≤30%.

[0042] Wherein, the aluminum ingot can be a cast aluminum alloy with the grade A356.2 in the American ASTM B179:2006 standard, and the main components and the weight percentages of each component are: Si: 6.5-7.0%; Fe: ≤0.10%; Cu : ≤0.08%; Mn: ≤0.05%; Mg: 0.30~0.45%; Ti: 0.07~0.20%; Zn≤0.05%; Al is the balance. A356.2 brand aluminum alloy is used, its Fe: ≤0.10%, and the proportion of other elements in the alloy...

Embodiment 1

[0056] Put the aluminum ingots and returned materials into the smelting furnace at a ratio of 8:2, melt them, and the melting temperature is 740°C, and wait for the molten aluminum to reach the water discharge temperature of 750°C; before discharging the water, detect the chemical composition of the molten aluminum in the melting furnace, and pass through the molten aluminum Enter inert gas for rotary degassing so that the density index of the aluminum liquid is ≤0.05%; the temperature of the die-casting aluminum alloy liquid is 700°C, and the alloy liquid is formed into parts through a special mold and an ultra-low-speed process; the completed die-casting blank is subjected to solid solution and aging For treatment, the solid solution temperature is 530°C, heat preservation for 4 hours, quenching treatment in 60S, and the aging treatment temperature is controlled at 160°C, heat preservation for 4 hours.

[0057] Examples 2-5 and Comparative Examples 1-3 were prepared according...

Embodiment 6

[0065] The die casting prepared in Example 1 (raw material A356.2) was laser welded to the side plate of the extruded profile, and the performance of the weld was tested: the porosity was 0.8%, and the average welding strength was 23KN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com