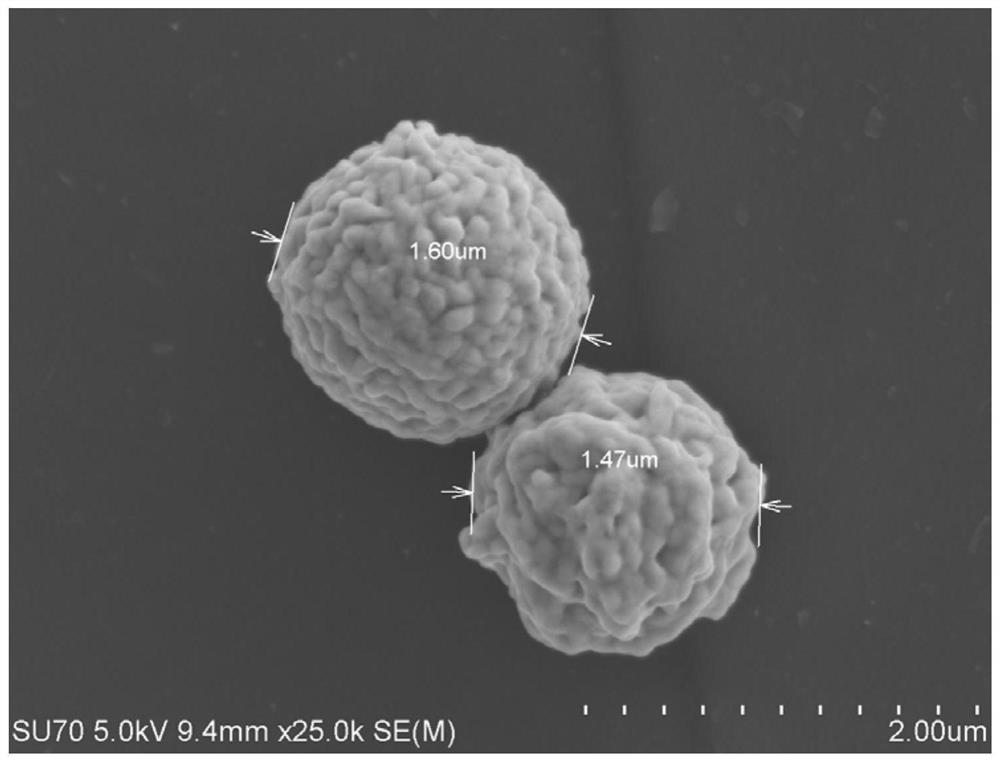

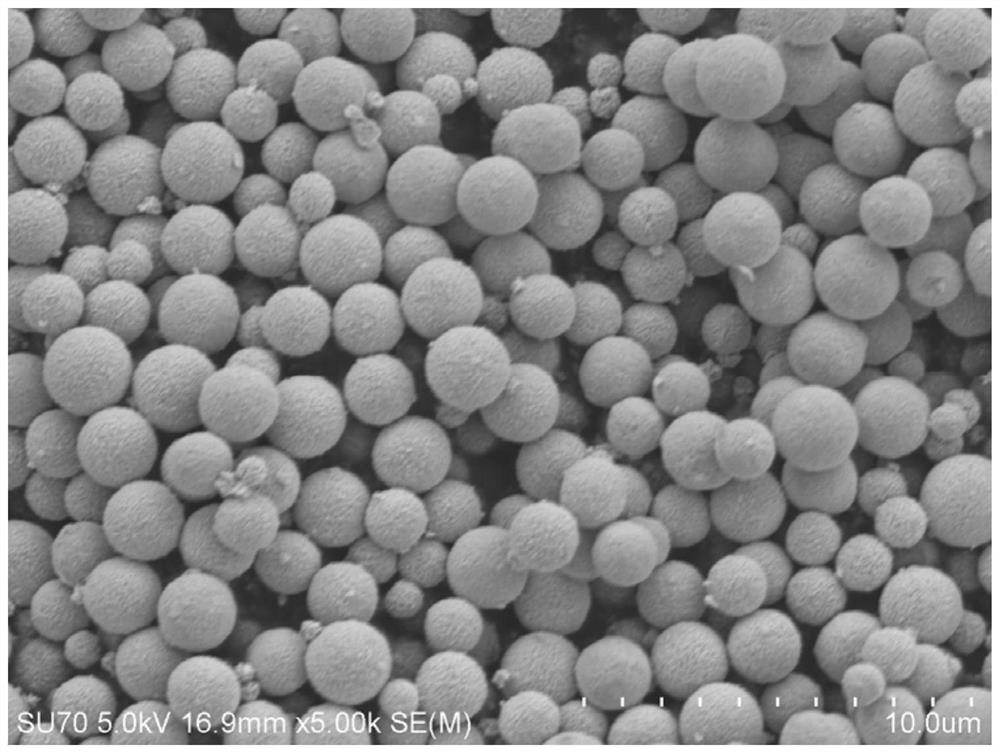

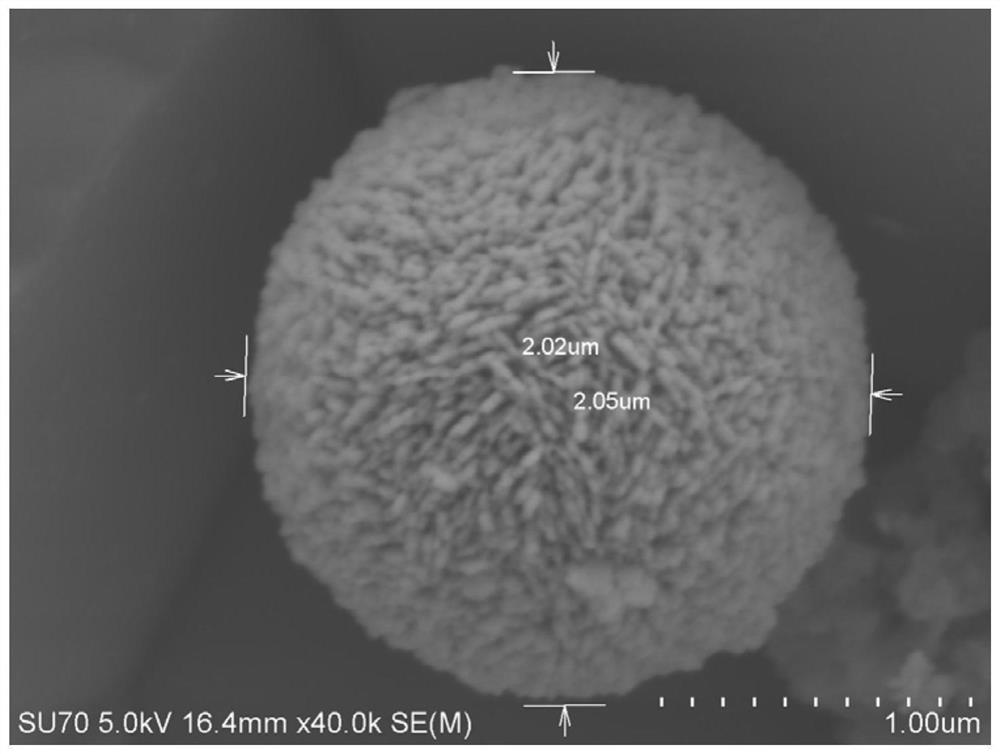

Micron-sized spherical silver powder and preparation method thereof

A micron-scale, spherical technology, applied to conductive materials dispersed in non-conductive inorganic materials, photovoltaic power generation, etc., can solve the problems of limiting the preparation of efficient conductive silver paste, poor sphericity and size control of silver powder, etc., to achieve a good surface Shape, reduce production cost, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of micron-scale spherical silver powder, comprising the following steps:

[0033] S1, preparing a silver nitrate solution, adding trisodium citrate to the silver nitrate solution and mixing to obtain a precursor solution;

[0034] S2, preparing an ascorbic acid solution, adding gum arabic, polyvinylpyrrolidone and polyethylene glycol to the ascorbic acid solution to obtain a reducing agent solution;

[0035] S3, under the condition of 20-60° C. and protected from light, quickly pour the precursor solution into the reducing agent solution, and keep stirring until the reaction is completed, and the micron-sized spherical silver powder is obtained.

[0036] The principle of this preparation method is: add trisodium citrate to the silver nitrate solution, the citrate root combines with silver ions to form a deposition salt, and then gradually releases silver ions during the reaction process, thereby reducing the reaction rate and better controlling the ...

Embodiment 1

[0047] (1) Preparation of silver solution A: first prepare a silver nitrate solution with a molar concentration of 0.118mol / L in a 50ml beaker, then add trisodium citrate with a silver nitrate mass ratio of 250:3 to obtain a silver-containing solution A;

[0048] (2) in the beaker of 50ml, prepare molar concentration and be the ascorbic acid solution of 0.114mol / L, add respectively the acacia gum (AG) that is 8% with respect to silver nitrate mass ratio, 2% polyvinylpyrrolidone (PVP, MW=58000 ) and 2% polyethylene glycol 4000 (PEG-4000), to obtain solution B;

[0049](3) In the case of continuous magnetic stirring, the silver solution prepared in step (1) is poured into the reducing agent solution B at a speed of 12.5ml / s. After the addition, the magnetic stirring is continued for 10min, and the stirring The speed is 500r / min, and the whole process is kept at room temperature and protected from light. After the reaction, the silver colloid solution was placed in an ultrasoni...

Embodiment 2

[0051] (1) Preparation of silver solution A: first prepare a silver nitrate solution with a molar concentration of 0.118mol / L in a 50ml beaker, then add trisodium citrate with a mass ratio of 250:3 to silver nitrate to obtain a silver-containing solution A;

[0052] (2) Preparation of reducing agent solution B: in a 50ml beaker, prepare a molar concentration of 0.114mol / L ascorbic acid solution, add respectively gum arabic (AG) and 2.5% polyvinylpyrrolidone relative to silver nitrate mass ratio (PVP, MW=58000) and 1.8% polyethylene glycol 4000 (PEG-4000) to obtain solution B;

[0053] (3) In the case of continuous magnetic stirring, the silver solution prepared in step (1) is poured into the reducing agent solution B at a speed of 12.5ml / s. After the addition, the magnetic stirring is continued for 10min, and the stirring The speed is 500r / min, and the whole process is kept at room temperature and protected from light. After the reaction, the silver colloid solution was plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com