Bacteria filter bag with good filter effect and preparation method thereof

A filter effect and filter bag technology, which is applied in the field of bacterial filter bags and its preparation, can solve the problems of poor antibacterial effect, achieve the effects of improving dispersion effect, enriching pore structure, and improving bacterial filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

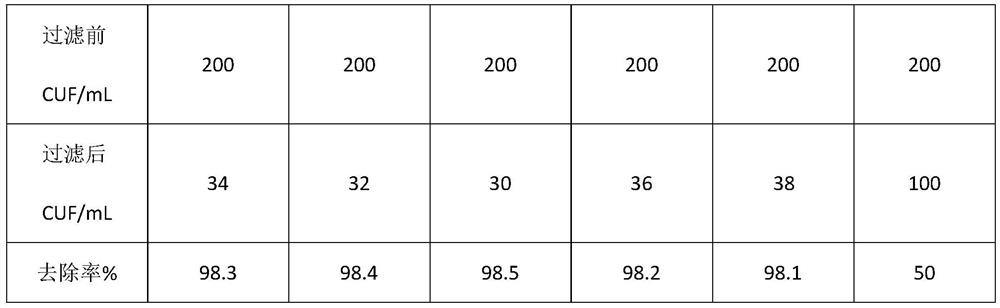

Examples

Embodiment 1

[0028] A preparation method for a bacterial filter bag with good filtering effect, comprising the steps of:

[0029] (1) Preparation of chitosan microspheres: Mix 100g polyoxyethylene and 15g fatty acid glycerides evenly, add 30g, 10wt% chitosan solution to it, emulsify at 25°C for 2h, then add 18g pentadiene Aldehydes were reacted at 60°C for 4 hours. After the reaction, the reaction product was centrifuged, washed and dried to obtain chitosan microspheres;

[0030] (2) Preparation of quaternized chitosan microspheres: uniformly disperse 100 g of chitosan microspheres in 800 g of acetone solvent, then add 60 g of phosphate ester quaternization reagent, and react at 45° C. for 6 h. After the reaction, the The reaction product is washed and dried to obtain quaternized chitosan microspheres;

[0031] (3) Preparation of SiO 2 / Quaternized chitosan microspheres: 25g tetraethyl orthosilicate, 15g absolute ethanol, 100g deionized water and 6g, 0.8mol / L NH 4 The Cl solution was mi...

Embodiment 2

[0035] A preparation method for a bacterial filter bag with good filtering effect, comprising the steps of:

[0036](1) Preparation of chitosan microspheres: 100g polyoxyethylene and 20g fatty acid glycerides were mixed evenly, 35g, 10wt% chitosan solution was added thereto, emulsified at 25°C for 3h, and then 20g pentadiene was added Aldehydes were reacted at 60°C for 4 hours. After the reaction, the reaction product was centrifuged, washed and dried to obtain chitosan microspheres;

[0037] (2) Preparation of quaternized chitosan microspheres: uniformly disperse 100 g of chitosan microspheres in 850 g of acetone solvent, then add 70 g of phosphate ester quaternization reagent, and react at 45° C. for 6 h. After the reaction, the The reaction product is washed and dried to obtain quaternized chitosan microspheres;

[0038] (3) Preparation of SiO 2 / Quaternized chitosan microspheres: 30g tetraethyl orthosilicate, 15g absolute ethanol, 100g deionized water and 7g, 1.0mol / L NH...

Embodiment 3

[0042] A preparation method for a bacterial filter bag with good filtering effect, comprising the steps of:

[0043] (1) Preparation of chitosan microspheres: 100g polyoxyethylene and 25g fatty acid glycerides were mixed evenly, 38g, 10wt% chitosan solution was added thereto, emulsified at 25°C for 2h, and then 20g pentadiene was added Aldehydes were reacted at 70°C for 4 hours. After the reaction, the reaction product was centrifuged, washed and dried to obtain chitosan microspheres;

[0044] (2) Preparation of quaternized chitosan microspheres: uniformly disperse 100 g of chitosan microspheres in 900 g of acetone solvent, then add 75 g of phosphate ester quaternization reagent, and react at 45° C. for 7 hours. After the reaction, the The reaction product is washed and dried to obtain quaternized chitosan microspheres;

[0045] (3) Preparation of SiO 2 / Quaternized chitosan microspheres: 35g tetraethyl orthosilicate, 20g absolute ethanol, 100g deionized water and 8g, 1.0mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com