Solid-phase microextraction head as well as preparation method and application thereof

A solid-phase microextraction head and solution technology, applied in the detection field, can solve problems such as complicated operation, sample interference, unsuitable elution, etc., and achieve the effects of saving costs, saving costs, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Method for preparing a tooth sign solid phase microexture head

[0052] 1. The 7 g of the polyacrylonitrile PAN powder is dissolved in 100 ml of dimethylformamide (DMF), and the mixture is constantly stirred at room temperature to ensure uniform dissolution.

[0053] 2, OASIS HLB particles (30 μm) are formed using a ball mill at 240 rpm for 2 hours.

[0054] 3, 1 g of HLB was mixed with 10 ml PAN solution to obtain the final PAN-HLB slurry. It was then mixed with 1800 rpm under the oscillator to be mixed 12 hours to provide a mixture of pellets sufficiently uniform.

[0055] 4, use the toothpick to pick up the PAN-HLB slurry, with a length of about 1 cm, so that it is evenly applied to the toothpick, and then take it once after drying.

[0056] 5. Even the toothpick in the solvent solution at a rate of 1500 rpm (methanol, isopropyl alcohol and acetonitrile (MeOH / IPA / ACN, 50: 25: 25) for a total of 15 minutes to remove the residue.

[0057] 6. Pretreatment of t...

Embodiment 2

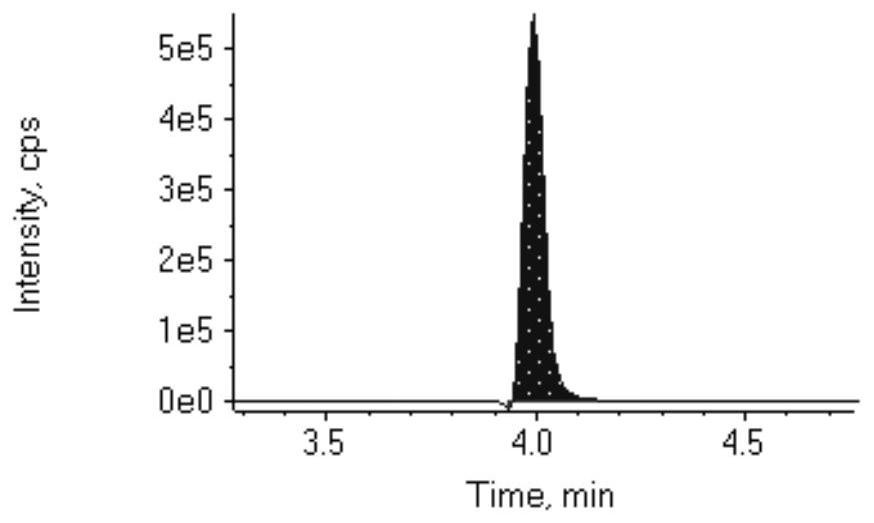

[0058] Example 2 Study on Adsorption Effect of Toothpog Follow Microenection

[0059] 1. Derived to a certain concentration of nitrofuran metabolite standards, specifically:

[0060] A 4 nitrofuran metabolite of 200 μl of concentration of 0.1 μg / ml was taken, and 17 ml of 0.125 mol / L hydrochloric acid solution and 1.0 ml of 2-nitrobenate were added, and the constant temperature oscillator was derived at a constant temperature oscillator of 37 ° C. The 1 ml of the potassium hydrogen phosphate solution was adjusted between pH 7.2 to 7.4 with a 1 mol / L sodium hydroxide solution and a water solution of 0.1 mol / L of hydrochloric acid.

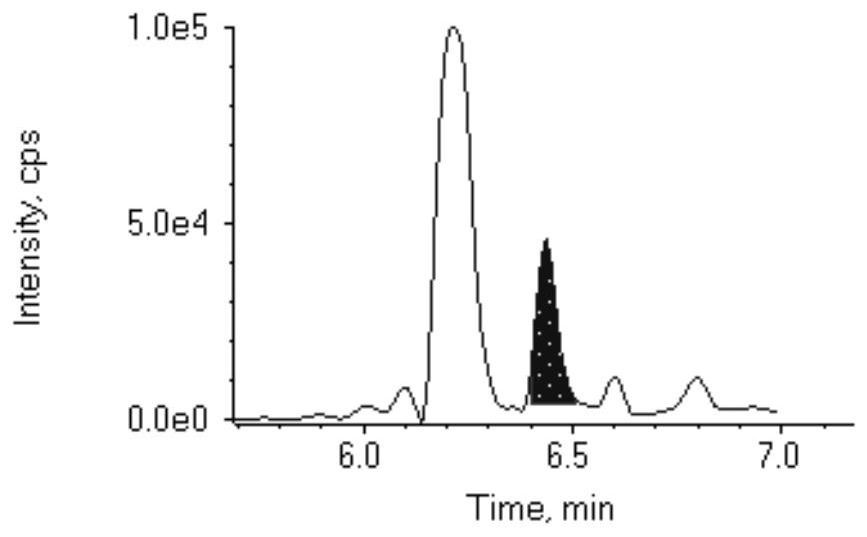

[0061] 2, the average derived standard is divided into two copies, one with ethyl acetate reaction, nitrogen blowing, reacting, and calculates the quality of derivatives 0 The other part was extracted with a prepreg for 3 minutes with a prepared toothg, and after removing the extract, the remaining liquid was reversed with ethyl acetate, and the...

Embodiment 3

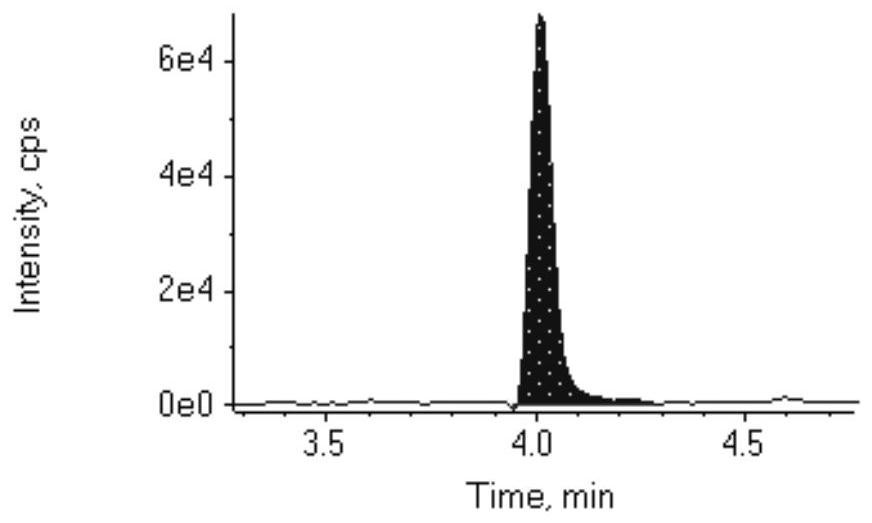

[0063] Example 3 Repeated Utilization of Toothpog Follow Microenest

[0064] 1. Treatment of the toothpog solid phase microextment of the residual sample is obtained 3 times in ethyl acetate, the nitrogen blowing, and retracted, and the desorption and residual case of the teeth signs and the microextament should be studied.

[0065] The results showed that the toothpog solid phase of the present invention was taken out, and the desorption rate was 99% at once, and the analysis rate was 100%, and the analysis was eluted by ethyl acetate, and the target can be adsorbed. All of the things were desirable, and there was no residue.

[0066] 2, the above-described treatment of the toothpick solid phase microexture is again performed, and the recovery rate is calculated.

[0067] In order to assess the repeatable use of the teeth signs, it is carried out by analyzing pork with 40 μl of NFS standard (concentration of 0.1 μg / mL), and the adsorption experiment of 5 cycles was carried out....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com