600 MPa-grade low-manganese nickel-containing alloying hot galvanizing dual-phase steel with enhanced broaching performance and production method thereof

A production method and hot-dip galvanizing technology, which are applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of poor flanging and hole-enlarging forming performance, and achieve improved flanging and hole-enlarging forming performance, The effect of eliminating banding and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention is further described below in conjunction with embodiment.

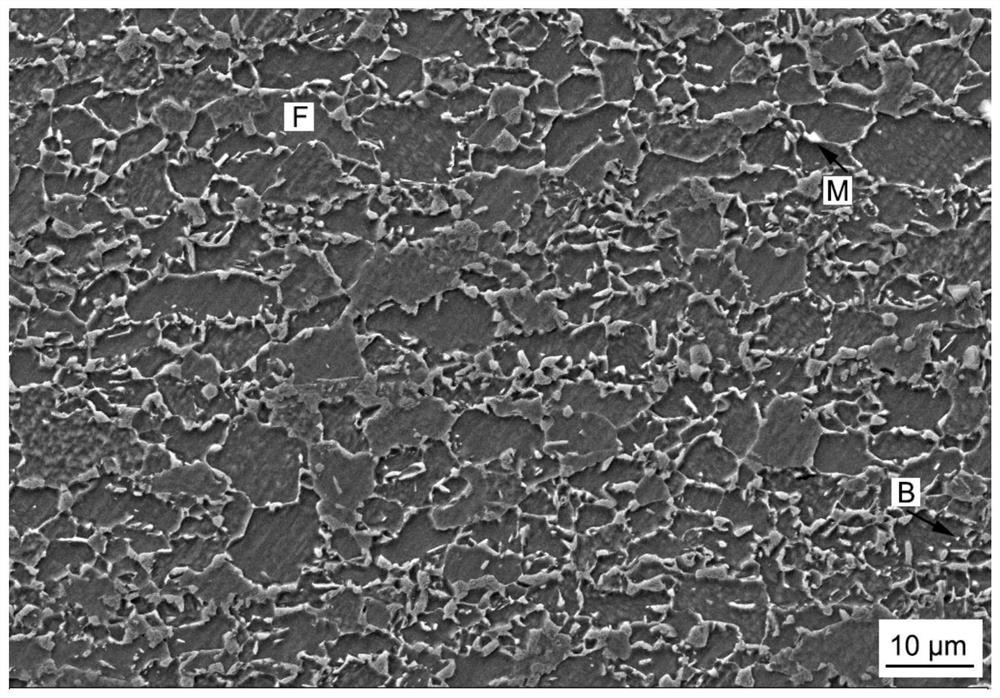

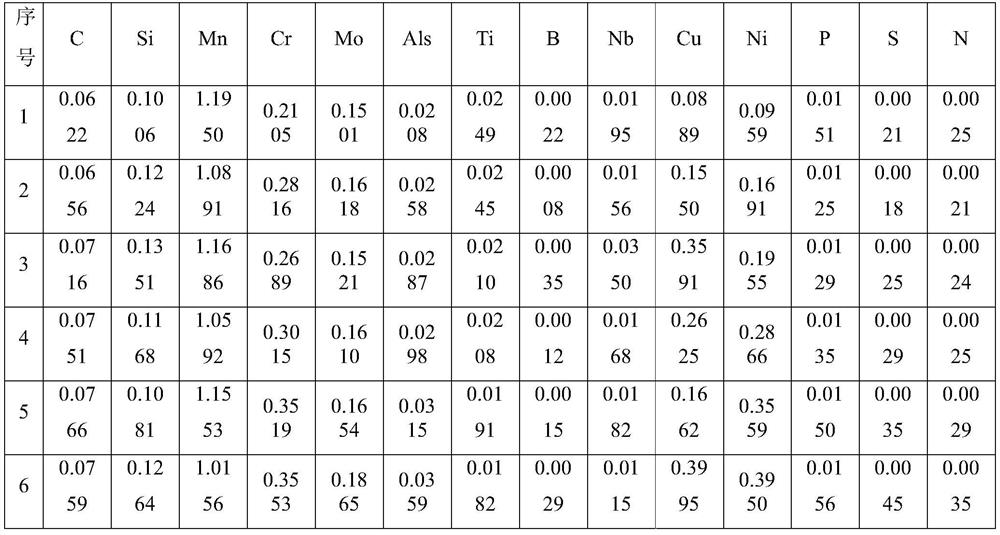

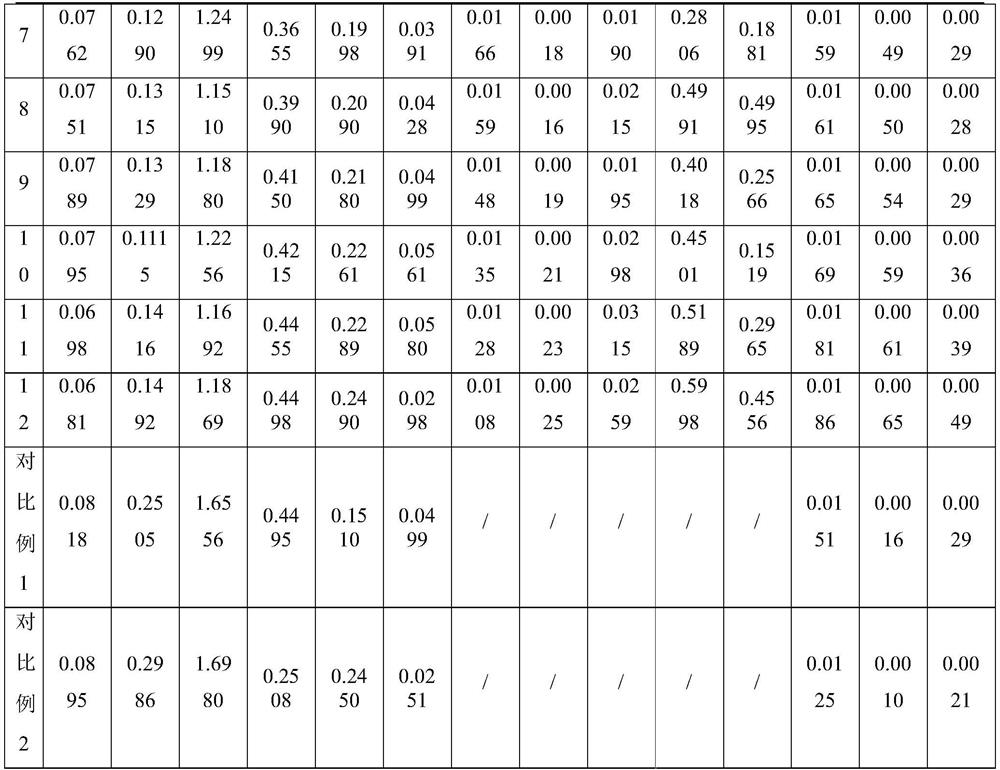

[0072] Table 1 shows the composition and mass percentage of main chemical elements of a 600MPa grade low-manganese nickel-containing alloyed hot-dip galvanized dual-phase steel with enhanced hole expansion performance of the present invention.

[0073] The chemical element composition and mass percentage (wt %) of table 1 embodiment and comparative example

[0074]

[0075]

[0076] Note: Nos. 1 to 12 in Table 1 are preferred embodiments of the present invention 1 to 12.

[0077] A kind of production method of the 600MPa level low-manganese nickel-containing alloyed hot-dip galvanized dual-phase steel with enhanced hole expansion performance of the present invention comprises the following steps:

[0078] (1) Pretreatment of molten iron, the bright side of the front slag removal ≥ 70.0%, the bright side of the rear slag removal ≥ 80.0%, the desulfurization target [S] of molten iron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com