IGFC system and method for conveying pulverized coal through high-temperature fuel cell anode tail gas

A high-temperature fuel cell and anode tail gas technology, applied in the field of IGFC system, can solve the problems of unfavorable gasifier cold gas efficiency, low temperature of high-purity nitrogen, and fuel chemical energy consumption, so as to improve cold gas efficiency and reduce fuel chemical energy , the effect of reducing air separation energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

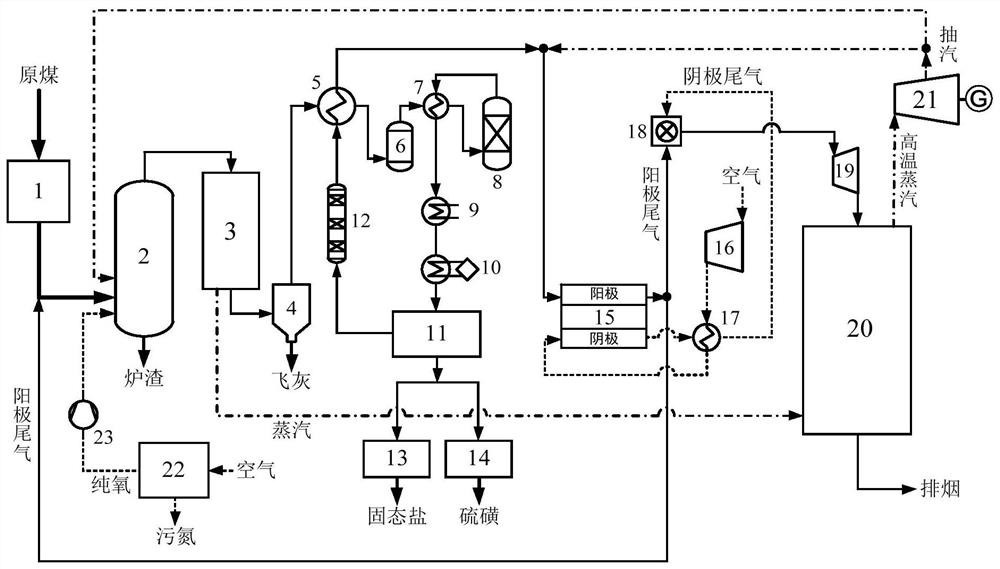

[0024] Such as figure 1 As shown, it is the IGFC system using high-temperature fuel cell anode tail gas to transport pulverized coal according to the present invention, which includes a coal preparation unit 1, a gasifier 2, a waste heat boiler 3, a dust removal unit 4, and a first gas heater connected in sequence 5. High temperature fuel cell 15, catalytic burner 18, gas turbine 19 and waste heat boiler 20.

[0025] The raw material produced at the outlet of the coal preparation unit 1 is dry coal powder, the anode outlet of the high temperature fuel cell 15 is connected to the outlet of the coal preparation unit 1, and the inlet of the gasifier 2 is connected to the outlet of the cryogenic air separation unit 22.

[0026] A flow valve is provided between the anode outlet of the high-temperature fuel cell 15 and the inlet of the gasifier 2 to control the flow rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com