Epoxy resin for closed composite electric appliance and preparation method thereof

A technology for epoxy resin and combined electrical appliances, applied in the field of epoxy resin for closed combined electrical appliances and its preparation, can solve the problems of volume resistivity, leakage resistance, tracking resistance, arc resistance, low thermal expansion, etc., and achieves superior process operability, mechanical The effect of low strength and excellent anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

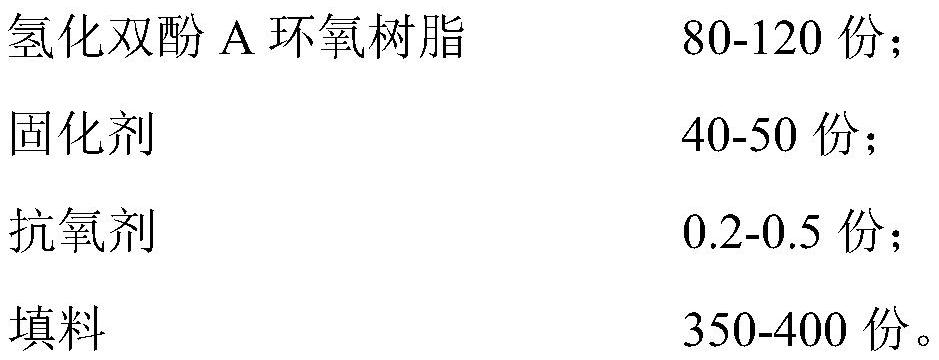

[0039] Embodiment 1 A kind of epoxy resin for closed combination electrical appliances, comprises the raw material of following weight part:

[0040]

[0041]

[0042] Among them, the epoxy equivalent of the hydrogenated bisphenol A epoxy resin is 221eq / 100g; the viscosity at 25°C is 2845mPas.

[0043] Preparation method: comprising the following steps:

[0044] (1) Firstly, after melting the modified hydrogenated bisphenol A epoxy resin at 120±5°C, set it aside; add the modified hydrogenated bisphenol A epoxy resin with 100 times the amount of antioxidant 703 to the amount of antioxidant 703 in the formula The resin is uniformly dispersed with a high-speed stirrer to obtain a mixture 1; the mixture 1 is added to a mixing tank containing the remaining modified hydrogenated bisphenol A epoxy resin, stirred and dispersed uniformly to obtain a mixture 2;

[0045] (2) Add the electrical alumina filler pre-baked at 120±5°C into the mixture 2 in three batches, stir evenly and...

Embodiment 2

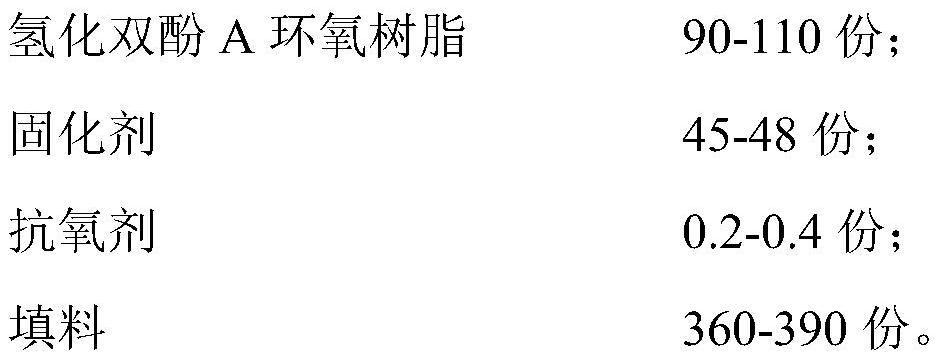

[0047] Embodiment 2 An epoxy resin for a closed combined electrical appliance, comprising the following raw materials in parts by weight:

[0048]

[0049] Among them, the epoxy equivalent of the hydrogenated bisphenol A epoxy resin is 247eq / 100g; the viscosity at 25°C is 3458mPas.

[0050] Preparation method: comprising the following steps:

[0051] (1) Firstly, after melting the modified hydrogenated bisphenol A epoxy resin at 120±5°C, set it aside; add the modified hydrogenated bisphenol A epoxy resin with 100 times the amount of antioxidant 703 to the amount of antioxidant 703 in the formula The resin is uniformly dispersed with a high-speed stirrer to obtain a mixture 1; the mixture 1 is added to a mixing tank containing the remaining modified hydrogenated bisphenol A epoxy resin, stirred and dispersed uniformly to obtain a mixture 2;

[0052](2) Add the electrical alumina filler pre-baked at 120±5°C into the mixture 2 in three batches, stir evenly and then add the cu...

Embodiment 3

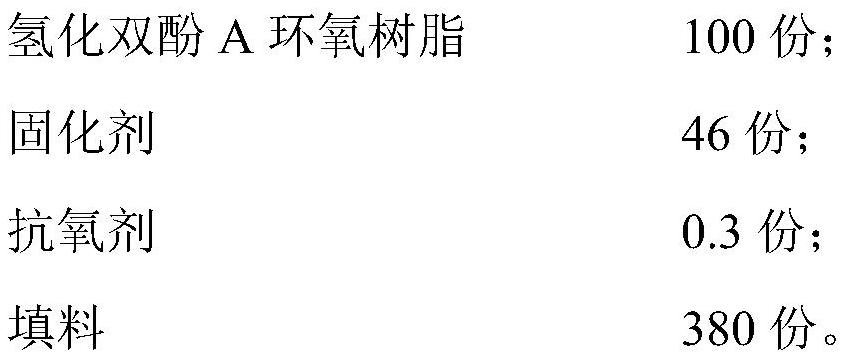

[0054] Embodiment 3 An epoxy resin for a closed combined electrical appliance, comprising the following raw materials in parts by weight:

[0055]

[0056] Among them, the epoxy equivalent of the hydrogenated bisphenol A epoxy resin is 236eq / 100g; the viscosity at 25°C is 3246mPas.

[0057] Preparation method: comprising the following steps:

[0058] (1) Firstly, after melting the modified hydrogenated bisphenol A epoxy resin at 120±5°C, set it aside; add the modified hydrogenated bisphenol A epoxy resin with 100 times the amount of antioxidant 703 to the amount of antioxidant 703 in the formula The resin is uniformly dispersed with a high-speed stirrer to obtain a mixture 1; the mixture 1 is added to a mixing tank containing the remaining modified hydrogenated bisphenol A epoxy resin, stirred and dispersed uniformly to obtain a mixture 2;

[0059] (2) Add the electrical alumina filler pre-baked at 120±5°C into the mixture 2 in three batches, stir evenly and then add the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com