A kind of garlic dregs-based liquid plastic film and preparation method thereof

A technology of liquid mulching film and garlic residue is applied in the field of agricultural mulching film, which can solve the problems of water retention, weakened thermal insulation effect, single function, destruction of agricultural soil ecological environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

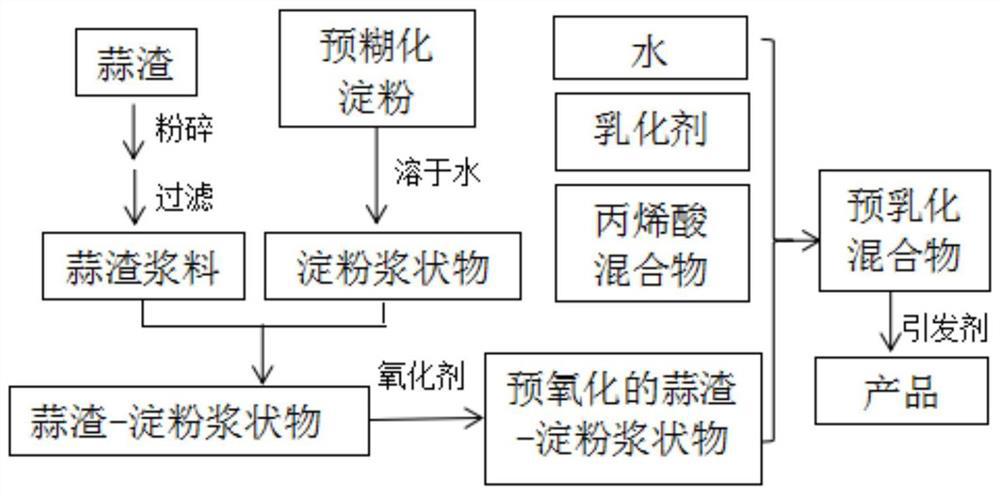

Method used

Image

Examples

Embodiment 1

[0040] (1) the garlic residue is pulverized into a garlic residue slurry with a pulverizer, and the garlic residue slurry obtained is filtered with a screen, so that the garlic residue particle size in the filtered garlic residue slurry is less than 10 meshes;

[0041] (2) mixing pregelatinized starch and water into starch slurry at 28°C, wherein the mass ratio of pregelatinized starch and water is 0.15:1;

[0042] (3) mixing the garlic residue slurry obtained in step (1) with the starch slurry obtained in step (2), and stirring at 35° C. for 1 h at a stirring speed of 200 r / min to obtain garlic residue-starch slurry , the mass ratio between the garlic residue slurry and the starch slurry is 0.09:1;

[0043] (4) the garlic residue-starch slurry obtained in step (3) is added to the three-necked flask equipped with a stirrer, a thermometer and a condenser, then an aqueous oxidant solution is added to the flask while stirring at 80°C, and the stirring speed is 1500r / min, the sti...

Embodiment 2

[0049] (1) the garlic residue is pulverized into a garlic residue slurry with a pulverizer, and the garlic residue slurry obtained is filtered with a screen, so that the garlic residue particle size in the filtered garlic residue slurry is less than 10 meshes;

[0050] (2) mixing pregelatinized starch and water into starch slurry at 32°C, wherein the mass ratio of pregelatinized starch and water is 0.2:1;

[0051] (3) mixing the garlic residue slurry obtained in step (1) with the starch slurry obtained in step (2), and stirring at 28° C. for 2 h at a stirring speed of 1000 r / min to obtain garlic residue-starch slurry , the mass ratio between the garlic residue slurry and the starch slurry is 0.5:1;

[0052] (4) the garlic residue-starch slurry obtained in step (3) is added to the three-necked flask equipped with a stirrer, a thermometer and a condenser, and then the oxidant aqueous solution is added to the flask while stirring at 88°C, and the stirring speed is 1000r / min, the...

Embodiment 3

[0058] (1) the garlic residue is pulverized into a garlic residue slurry with a pulverizer, and the garlic residue slurry obtained is filtered with a screen, so that the garlic residue particle size in the filtered garlic residue slurry is less than 10 meshes;

[0059] (2) mixing pregelatinized starch and water into starch slurry at 25°C, wherein the mass ratio between pregelatinized starch and water is 0.18:1;

[0060] (3) mixing the garlic residue slurry obtained in step (1) with the starch slurry obtained in step (2), and stirring at 25° C. for 3 h at a stirring speed of 2000 r / min to obtain garlic residue-starch slurry , the mass ratio between the garlic residue slurry and the starch slurry is 0.3:1;

[0061] (4) the garlic dregs-starch slurry obtained in step (3) is added to the three-necked flask equipped with a stirrer, a thermometer and a condenser, then at 85 ° C, an aqueous oxidant solution is added to the flask while stirring, and the stirring speed is 500r / min, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com