Device and method for treating sewage by using dry strength agent production wastewater

A technology for the production of waste water and dry strength agents, which is applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc., can solve the problems of high cost and difficult treatment of dry strength agent production waste water, etc. The problem of production wastewater, the effect of close integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

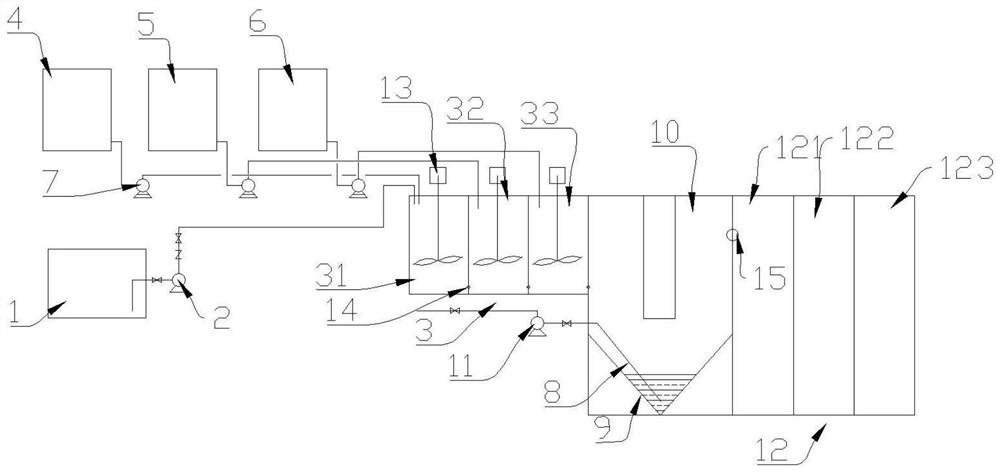

[0028] This embodiment provides the structure of a device for producing waste water and treating sewage by using a dry strength agent:

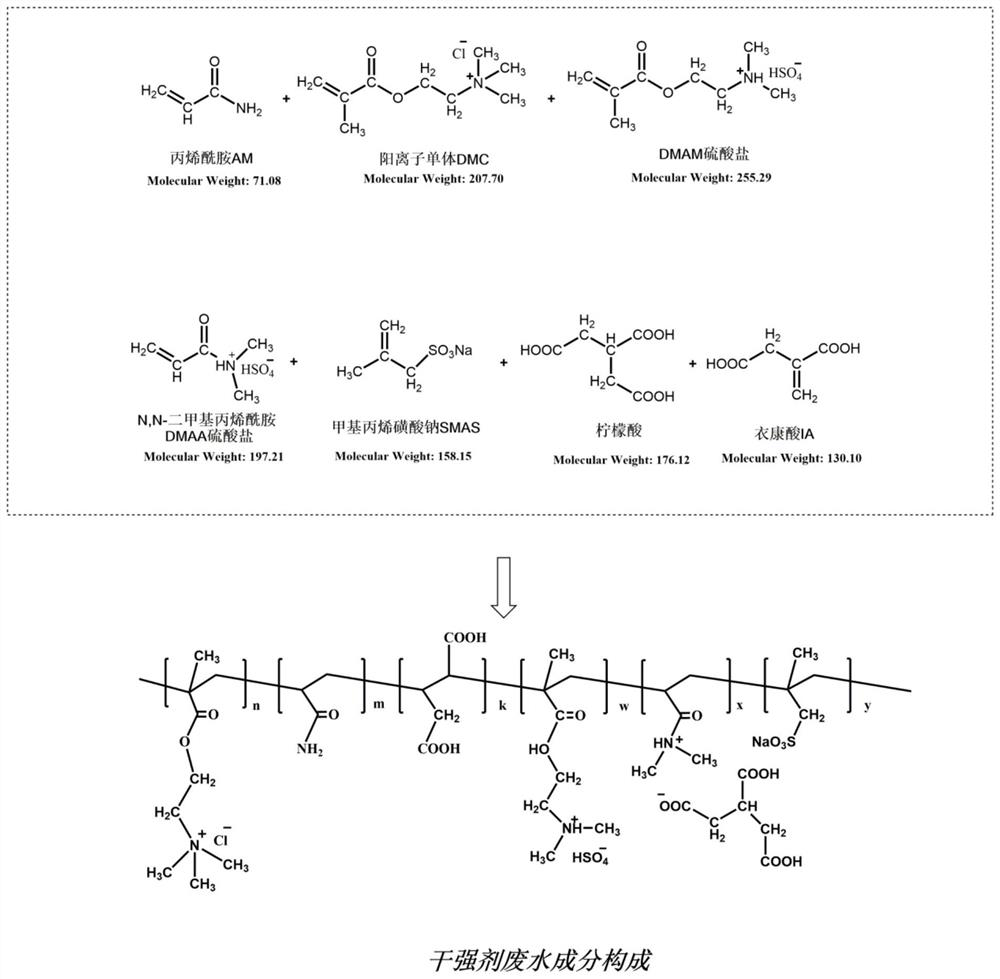

[0029] Such as figure 1 , figure 2 as shown, figure 1 It is a structural schematic diagram of the present invention, figure 2 It is the chemical formula of the components of the dry strength agent wastewater of the present invention. In the present invention, the dry strength agent wastewater refers to the wastewater generated in the process of producing the dry strength agent. The components of the wastewater include water and the accompanying drawings figure 2 One or more of intermediate products and raw materials; the present invention includes a sewage regulating tank 1, a sewage coagulation tank 3, a coagulation sedimentation tank 10 and a biochemical treatment tank 12 connected in sequence through pipelines, and the biochemical treatment tank 12 includes Anaerobic pool 121, A pool 122, and O pool 123 connected in sequence;

[003...

Embodiment 2

[0033] The present embodiment provides the method for utilizing dry strength agent to produce waste water and treat sewage, comprising the following steps:

[0034] S1: Pass the sewage to be treated into the sewage regulating tank 1, introduce the sewage into the first coagulation tank 31 through the sewage pump 2, and adjust the pH of the sewage in the first coagulation tank 31, if the pH of the sewage is acidic , then feed an appropriate amount of 30% liquid alkali to adjust the pH, if the pH of the sewage is alkaline, then feed 15% hydrochloric acid to adjust the pH, and adjust the pH of the sewage in the first coagulation tank 31 to 7-8.5;

[0035] S2: The sewage treated in S1 is further introduced into the second coagulation tank 32, and the polyaluminum chloride is continuously injected into the second coagulation tank 32 for preliminary purification of the sewage, and the mass concentration of the polyaluminum chloride is 1 -4%, the amount added is 3-10% of the sewage w...

Embodiment 3

[0039] The present embodiment provides specific examples, utilize dry strength agent to produce waste water and treat sewage by the device of embodiment 1 and the method of embodiment 2, specific method is as follows:

[0040] S1: Pass the sewage to be treated into the sewage regulating tank 1, wherein the pH of the sewage is 4.28, the COD content is 9218mg / L, the NH3-N content is 280.28mg / L, the TN content is 430mg / L, and the TP The content is 0.63mg / L, and the conductivity is 2110S / m. The above-mentioned sewage is introduced into the first coagulation tank 31 through the sewage pump 2, and an appropriate amount of 30% liquid alkali is introduced to adjust the pH. The pH of the sewage is adjusted to 7-8.5;

[0041] S2: The sewage treated in S1 is further introduced into the second coagulation tank 32, and the polyaluminum chloride is continuously injected into the second coagulation tank 32 for preliminary purification of the sewage, and the mass concentration of the polyalum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com