CQD/UiO-66 composite photocatalytic material, and preparation method and application thereof

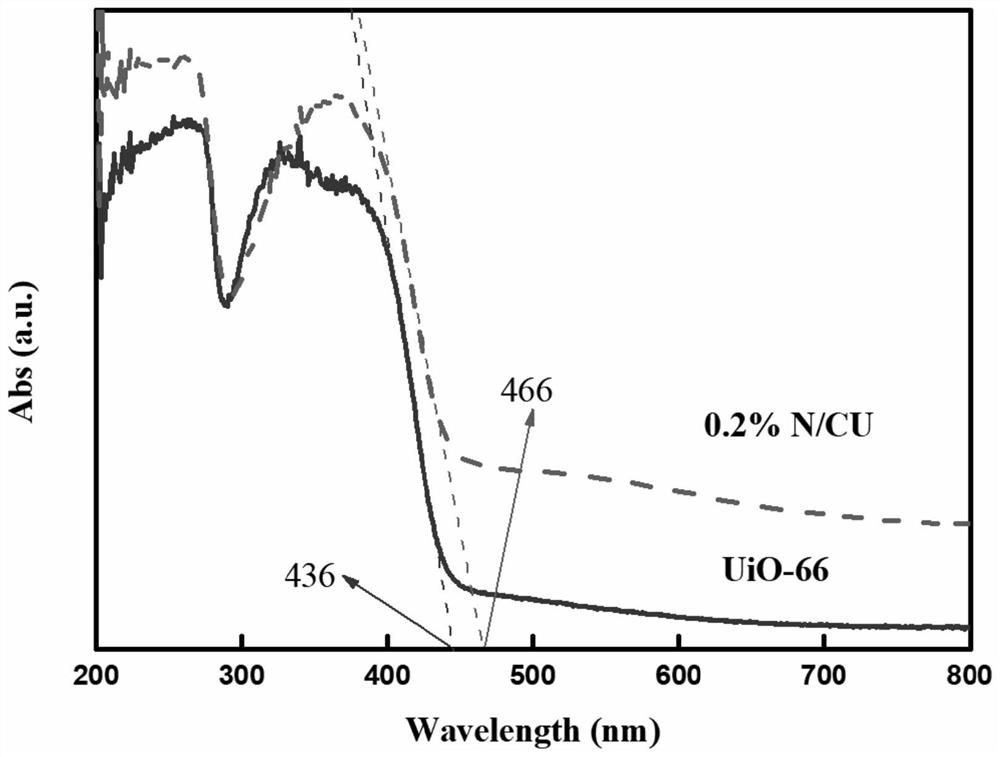

A composite photocatalysis, uio-66 technology, applied in the field of CQD/UiO-66 composite photocatalytic materials and its preparation, can solve the problem of high recombination rate of electrons and holes, achieve good photocatalytic activity, increase active sites, The effect of reducing compounding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the above CQD / UIO-66 composite photocatalytic material includes the following steps:

[0028] (1) After drying the flower shell 100 ° C, pulverized 3 times in the pulverizer, and the resulting peanuts powder sealing bag is spare. A certain amount of peanut powder and urea were dissolved in 60 ml of deionized water, and after half an hour, transferred to the polytetrafluoroethylene reaction kettle to carry out the hydrothermal reaction, and the resulting reaction solution was filtered, and the drying was dried. To obtain a solid powder of the CQD carbon quantum point.

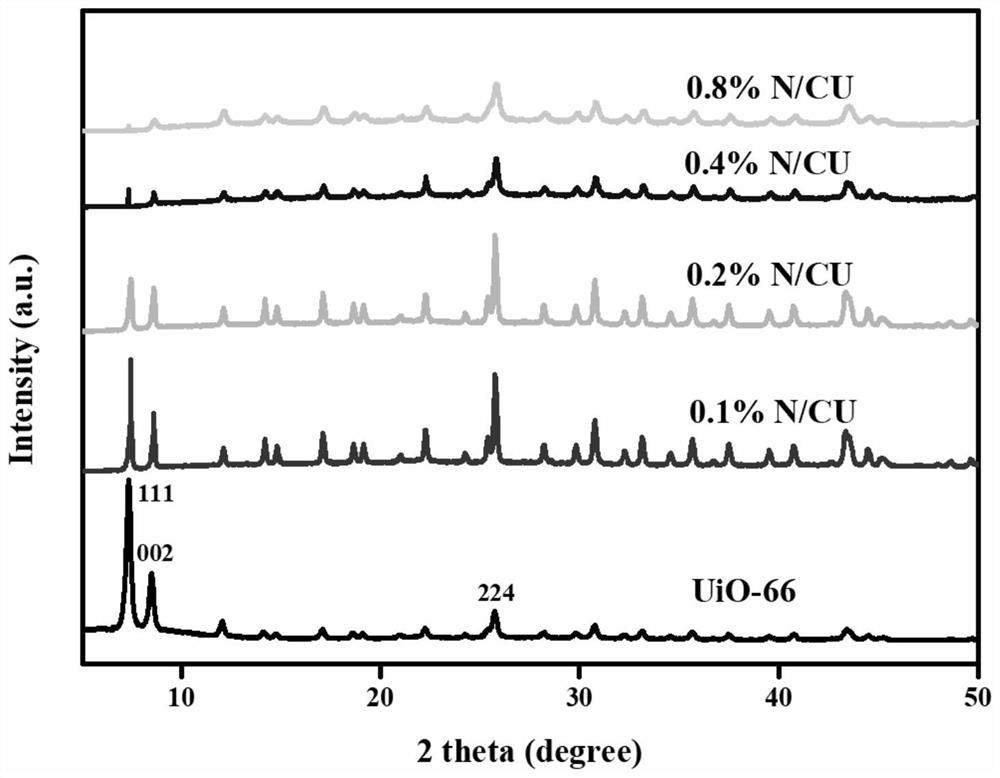

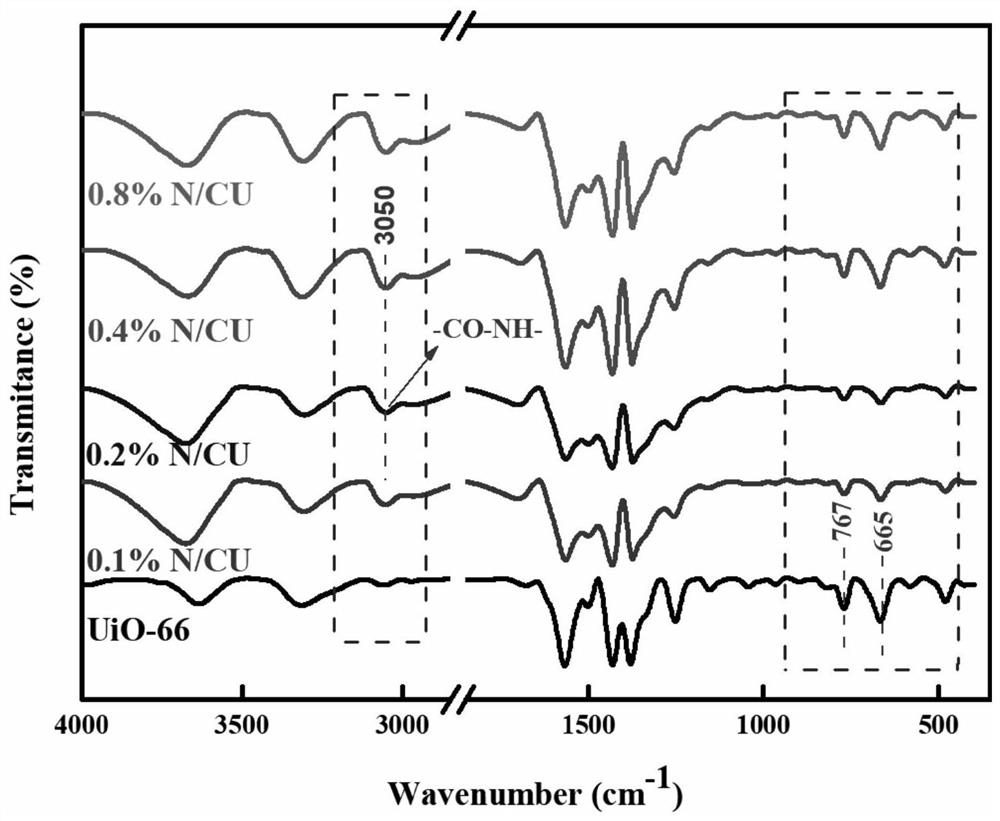

[0029] (2) Sell a certain amount of tetrachloride and 2-amino group terephthalic acid ultrasound in 50 mln, N-dimethylformamide solution, and this solution is illusted as solution A. Weigh a certain amount of CQD carbon quantum dot to the solution A, continue to ultrasonically completely dissolve, transfer the mixed solution to the polytetrafluoroethylene reaction kettle for solven...

Embodiment 1

[0039] (1) After drying the waste peanut shell 100 ° C, pulverized 3 times in the pulverizer, and the resulting peanuts powder sealing bag is spare. It is weighed 3.0 g of peanut shell powder, 3.0 g of urea, dissolved in 60 mL of deionized water, and after half an hour, transfer to a polytetrafluoroethylene reaction kettle reaction 18h at 200 ° C, after cooling to room temperature, the resulting reaction liquid The resulting clear solution was dialyzed for three days with a 1000 dA dialysis bag, and then a water was transferred once, and the Cqd solid powder was obtained.

[0040] (2) Weigh 0.2475 g of zirconium chloride, 0.1924 g 2-amino phenylene terephthalic acid, after ultrasonic dissolution in 50 ml n, N-dimethylformamide solution, add 0.001 g of CQD, continue to ultrasound to completely dissolve, The mixture was transferred to a 100 mL of the high pressure reactor at 120 ° C for 24 h, and after cooling to room temperature, the resulting sample was centrifuged with N, N-dimet...

Embodiment 2

[0042] (1) After drying the waste peanut shell 100 ° C, pulverized 3 times in the pulverizer, and the resulting peanuts powder sealing bag is spare. 3G peanuts powder and 1.5 g of urea were weighed in 60 ml of deionized water. After half an hour, transferred to a polytetrafluoroethylene reaction kettle at 200 ° C for 18 h, after cooling to room temperature, the resulting reaction liquid Filtration, the resulting clear solution was dialyzed for three days with a dialysis bag of 1000 dA, and a water was changed once every 4h, and the Cqd solid powder was obtained.

[0043] (2) Weigh 0.2475 g of zirconium chloride, 0.1924 g 2-amino terephthalic acid, after ultrasonic dissolution in 50 ml n, N-dimethylformamide solution, add 0.002 g of CQD, continue to ultrasound to completely dissolve, The mixture was transferred to a 100 mL of the high pressure reactor at 120 ° C for 24 h, and after cooling to room temperature, the resulting sample was centrifuged with N, N-dimethylformamide and met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com