Novel B1 electric wire

A new type of wire and technology, applied in the direction of circuits, electrical components, insulated cables, etc., can solve the problems of poor compatibility, poor dispersion of flame retardants, and affecting service life, etc., to achieve heat release and corrosion reduction, excellent electrical Insulation properties, effects of excellent flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

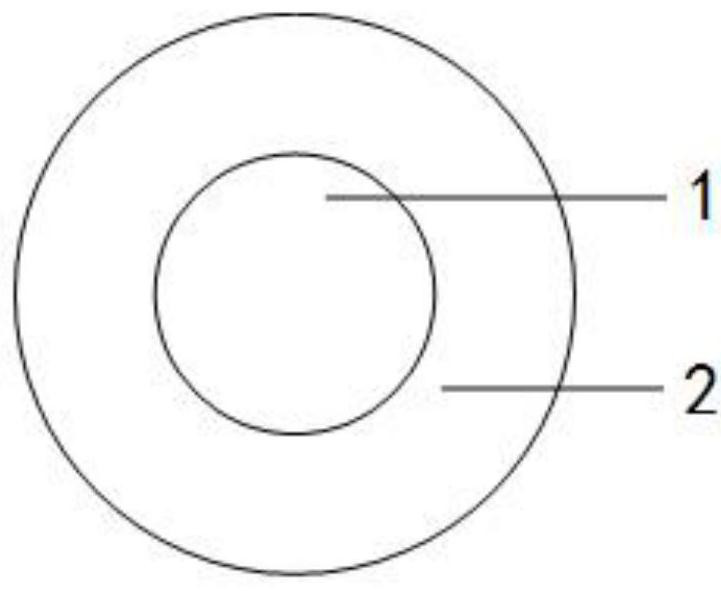

[0018] see figure 1 , the new B1 electric wire shown in the figure includes a conductor 1 and a B1 insulating material 2 coated on the conductor 1, and the B1 insulating material 2 is irradiated and cross-linked, so that the material changes from a linear shape to a three-dimensional network structure, which can be obtained by Melting but not melting, with better heat resistance. Conductor 1 is a copper conductor or a tinned copper conductor.

[0019] B1 insulating material uses polyolefin composed of ethylene-vinyl acetate copolymer, polyethylene and polyolefin elastomer as the base material; at the same time, the flame retardant is surface treated to improve the compatibility of magnesium hydroxide and polymer.

[0020] In a preferred embodiment of the present invention, the B1 insulating material is prepared from the following raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com