A drying device for ceramic blanks

A drying device, a technology made of ceramics, applied in the direction of ceramic products drying, drying, drying machine, etc., can solve the problems of complex conveyor belt or chain transmission structure, high operation and maintenance costs, long transmission distance, etc., to achieve the green body Good drying effect, compact structure, and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

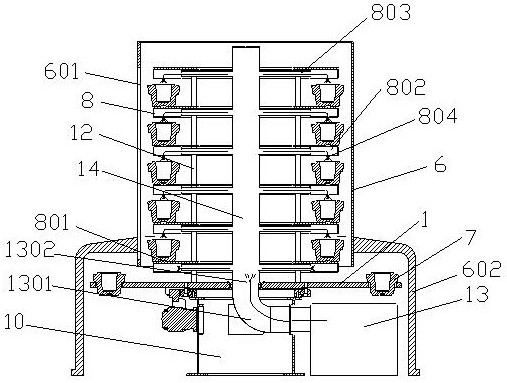

[0021] See figure 1 ——5, the drying device for ceramic blanks provided by the present invention includes a disc worktable 1 driven by a power device to rotate intermittently, and the diameter of the disc worktable 1 is smaller than that of the disc. Table 1 and the 6-layer heating plate 8 (usually 2 to 8 layers of drying plates 8) that rotates with the disk table 1 is fixed relative to the disk table 1 and is arranged on the disk table 1 to The outer shell 6 covered by the heating plate 8, and the heating device 13 that provides hot air into the outer shell 6; The hot air main pipe 14 is provided, and the heating plate 8 is provided with a hot air chamber that communicates with the hot air main pipe 14; except for the heating plate 8 of the lowermost layer, the bottom of the other heating plates 8 is provided with a hot air outlet 804 that communicates with the hot air chamber. The side of the outer shell 6 is provided with a plaster mold exchange port 601 corresponding to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com