Clothes dryer control method

A control method and clothes dryer technology, which are applied in the field of clothes drying, can solve problems such as longer drying time and higher average power consumption, and achieve the effects of shortening drying time, saving energy consumption, and increasing drying temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

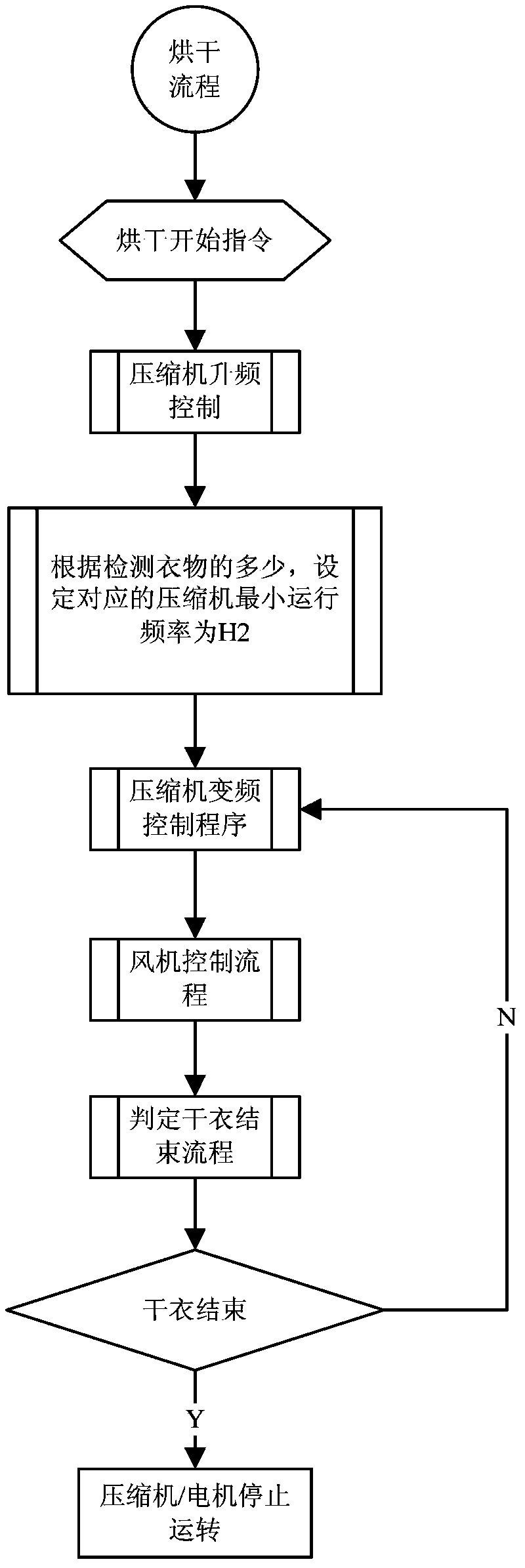

[0042] Such as Figure 4 As shown, this embodiment is a schematic diagram of the compressor up-frequency control process described above. The compressor up-frequency control refers to step-by-step frequency up-conversion at a fixed speed-up, and after each stage of frequency-up ends, it takes a stable and fixed time to enter the next step. stage, until the final frequency, the final frequency is the set frequency, or the operating frequency when the condenser temperature / compressor discharge temperature / compressor input current reaches the upper limit; each stage must detect whether the compressor is running at this stage Condenser temperature / compressor discharge temperature / compressor input current upper limit corresponding to the frequency. After the variable frequency compressor is started, the operating frequency of the compressor gradually increases from low speed to the final frequency H0, instead of directly operating at the highest frequency. The frequency increase o...

Embodiment 2

[0046] In this embodiment, within the set drying time range, it is judged when the surface temperature of the condenser reaches the set temperature value, and the longer the time, the more clothes, or the change of the condenser surface temperature within the set time period, The smaller the change in the surface temperature of the condenser per unit time, the more clothes there are, and the higher the minimum operating frequency of the compressor is set; otherwise, the opposite is true. For example, if the surface temperature of the condenser changes less than 20°C within 30 minutes, it is considered that there are more clothes, and the minimum operating frequency H2 of the compressor is set to 35Hz; The minimum operating frequency H2 of the compressor is set to 30Hz.

Embodiment 3

[0048] Within the set drying time range, judge the time when the humidity of the clothes in the dryer barrel reaches the set humidity value. The longer the time, the more clothes, or the change of the humidity of the clothes within the set time period, and the humidity of the clothes per unit time The smaller the change, the more laundry, and the higher the minimum operating frequency of the compressor is set. For example, if the humidity value is greater than 1900 within 30 minutes, it is considered that there are more clothes, and the minimum operating frequency H2 of the compressor is set to 35Hz; H2 is set to 30Hz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com