A chalcogen compound wafer-assisted localized growth method for transition metal chalcogenides

A technology of transition metal chalcogenides and chalcogenides, applied in the direction of binary selenium/tellurium compounds, metal selenides/tellurides, selenium/tellurium oxides/hydroxides, etc., which can solve unfavorable sample growth and sample inhomogeneity , affecting sample quality and other issues, to shorten the preparation time and avoid the effect of sample unevenness

Active Publication Date: 2022-06-03

PEKING UNIV

View PDF15 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the limitation of the mass transfer of the precursor and the influence of the low sublimation point of the sulfur source in the CVD process, on the one hand, there are a large number of sulfur defect vacancies in the prepared TMDC sample, which seriously affects the quality of the sample; on the other hand, it is affected by the concentration gradient of the precursor. lead to inhomogeneity of the sample

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

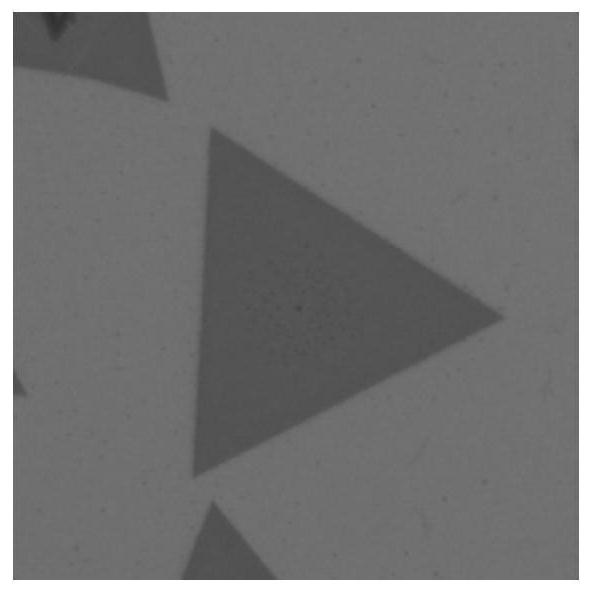

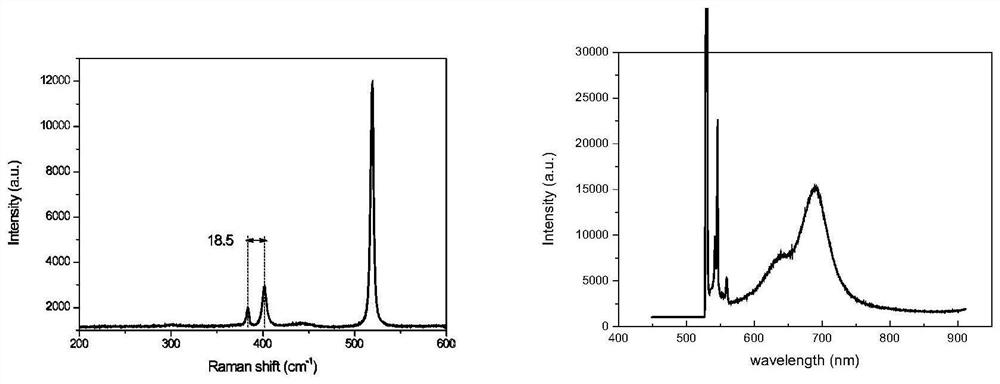

Embodiment 1

[0071] (2) using a ZnS wafer as a chalcogen supply source. will spin-coat uniform SiO

Embodiment 2

[0077] (2) using a ZnTe wafer as a chalcogen supply source. will spin-coat uniform SiO

Embodiment 3

[0082] (1) using oxygen plasma to pretreat the fused silica substrate to improve the hydrophilicity of the surface. then pass

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

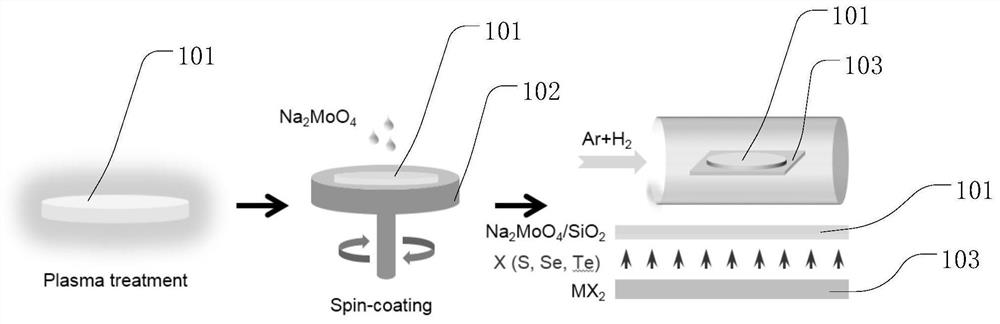

The invention relates to a method for assisting localized growth of transition metal chalcogenides on a chalcogenide compound wafer. The preparation method comprises the following steps: uniformly coating a prepared substrate with a layer of transition metal source and then buckling it on the chalcogenide On the compound wafer, the two construct a localized space and place it in a tube furnace. At high temperature, the chalcogen released from the chalcogen wafer reacts directly with the transition metal source on the substrate to obtain the corresponding transition metal compound on the substrate. Compared with the conventional CVD method, this method perfectly solves the problem of insufficient and uneven supply of precursor source diffusion during the growth process. With the characteristics of simple process, fast growth rate and strong universality, it can be used to prepare different kinds of transition metal chalcogenide (TMDC) materials, which provides a new idea for the preparation of two-dimensional materials.

Description

A chalcogenide wafer-assisted localized growth of transition metal chalcogenides Methods technical field The invention belongs to the technical field of two-dimensional material growth, especially relate to a kind of quick and easy preparation of transition metal sulfur method of family compounds. Background technique [0002] In recent years, with the rise of the graphene upsurge, two-dimensional materials have gradually attracted the attention of the majority of scientific researchers. In fact, In addition to the graphene we are now familiar with, two-dimensional materials have semiconducting properties of transition metal chalcogenides (TMDCs) and Hexagonal boron nitride (h‑BN) with insulator properties has also been extensively studied. Compared with graphene zero-bandgap material, TMDC is a Semiconductor 2D materials with band gap widths that vary with material thickness and therefore have unique electrical properties. Electron and optoelectronic properties,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01G39/06C01G41/00C01B19/04C01B19/00C01G9/08

CPCC01G39/06C01G41/00C01B19/007C01B19/004C01G9/08C01P2002/82Y02P70/50

Inventor 刘开辉左勇刚刘灿

Owner PEKING UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com