Welding wire for welding titanium/steel dissimilar materials and manufacturing process of welding wire

A technology of dissimilar materials and manufacturing processes, applied in welding/cutting media/materials, welding equipment, manufacturing tools, etc., can solve problems such as low contact strength, difficult drawing, brittle fracture, etc., to ensure consistency and promote welds Uniform distribution of elements, easy to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] This invention adopts the process of twisted wire to make Cu-Ni-Si alloy to manufacture titanium / steel dissimilar material welding wire. Based on the equilibrium phase diagram of Cu-Ni-Si alloy, when the Cu content is about 40%, the solidification structure only forms a common The grain structure is β-Ni3Si+α-Cu(Ni, Si), there is no embrittlement δ-Ni2Si, and the structure is relatively uniform.

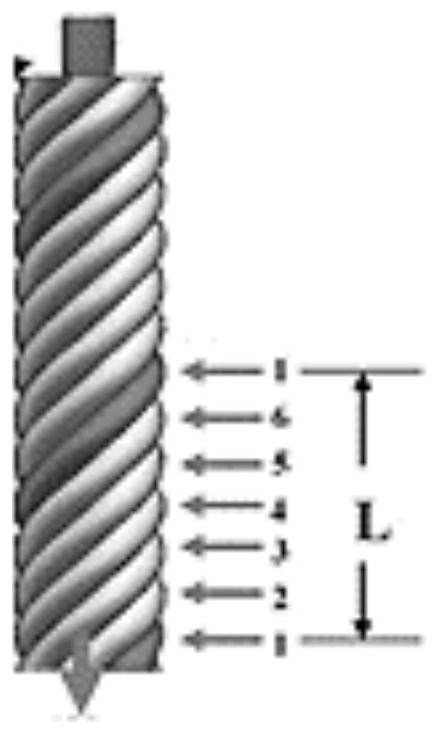

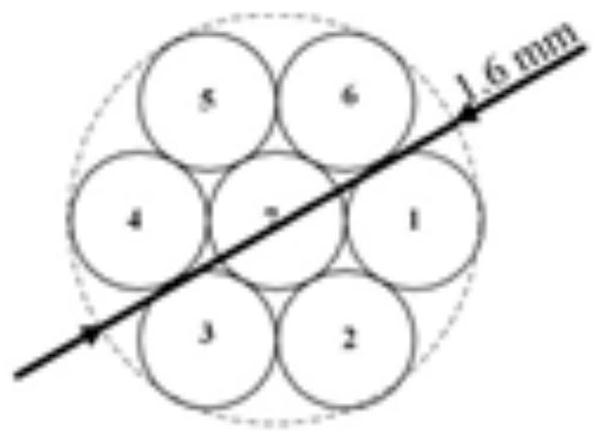

[0018] Such as figure 1 Shown, a kind of welding wire that is used for welding titanium / steel dissimilar material of the present invention is the stranded welding wire that is made of silicon bronze welding wire ERCuSi-A and Monel nickel-copper alloy welding wire ERNiCu-7, i.e. 5 strands of ERNiCu-7 welding wire and 2 Strands of ERCuSi-A welding wire are twisted, the diameter of the wire is 1.6mm, and it is composed of 7 filaments w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com