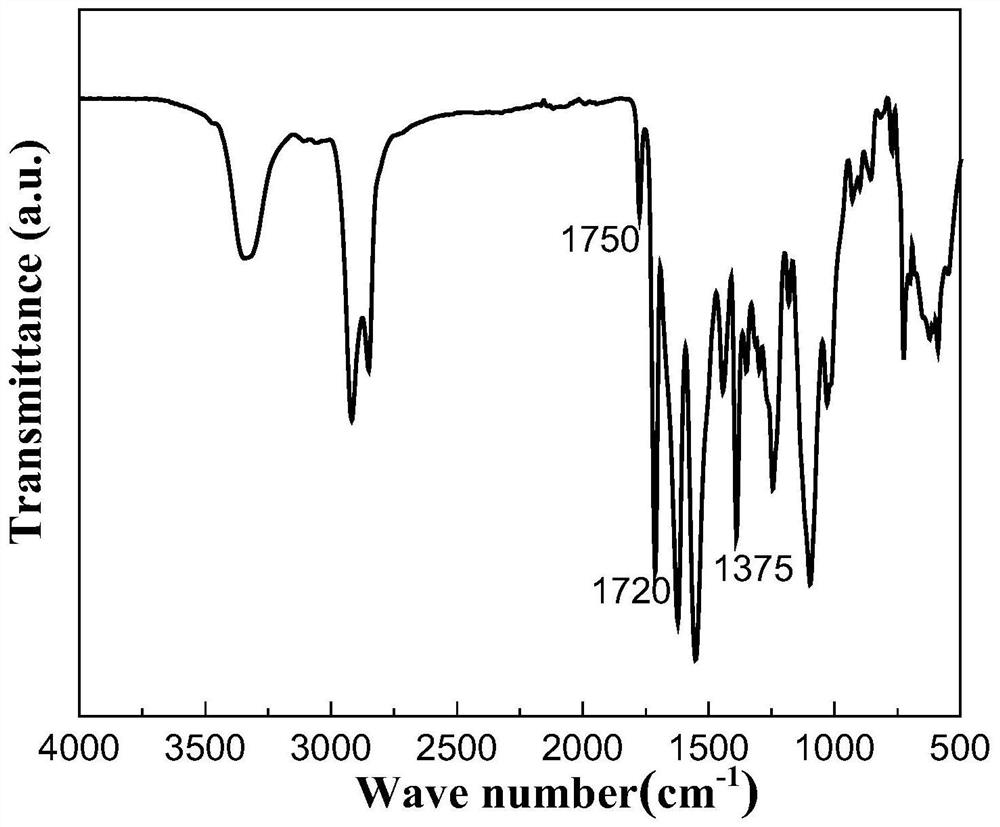

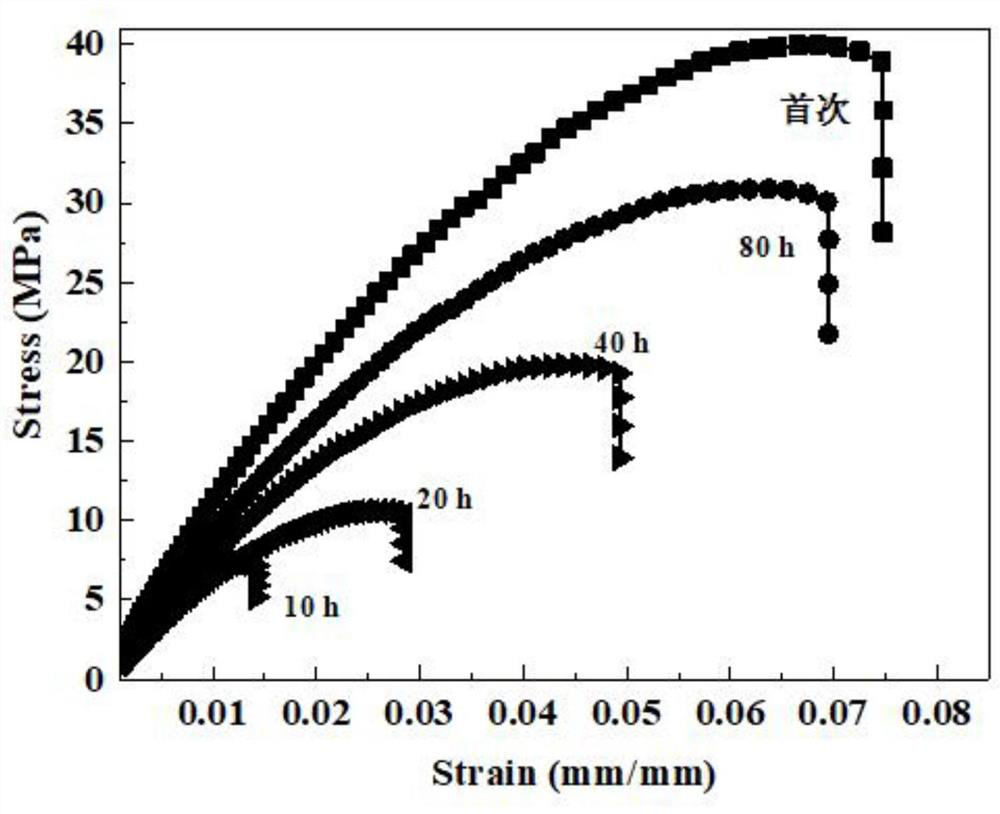

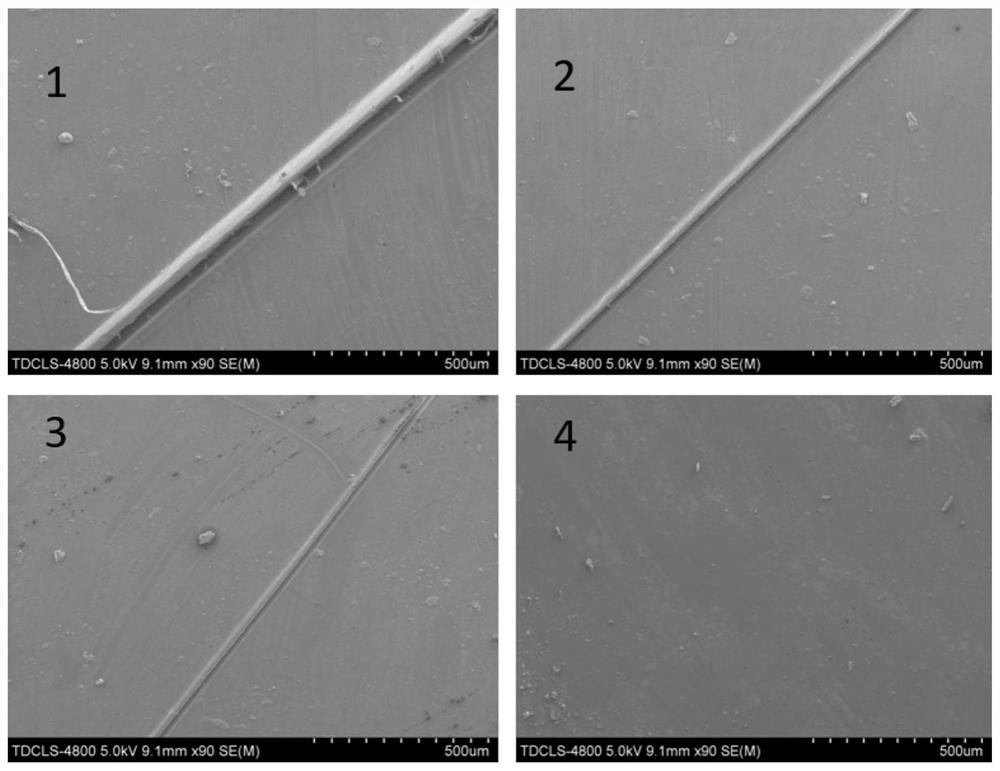

Polyimide self-repairing material based on hydrogen bonds and preparation method thereof

A self-healing material, polyimide technology, applied in the field of polymer materials, can solve problems affecting material performance, uneven temperature distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Synthesis of soft-segment EM based on hydrogen bond self-healing: First, 0.1mol 2,2'-(ethylenedioxy)diethylamine was dispersed in 100mL of ultra-dry N,N dimethylacetamide. Inject argon, and stir at -10°C for 30 minutes. Then, 0.1 mol of dicyclohexylmethane-4,4′-diisocyanate was dispersed in 20 mL of ultra-dry N,N dimethylacetamide. Then, the dicyclohexylmethane-4,4'-diisocyanate solution was slowly dropped into the reactor and continued to react for 5 hours to obtain a soft segment EM dispersion with hydrogen bond self-healing.

[0033] (2) Synthesis of polyamic acid (PAA): Firstly, at -10°C, under argon atmosphere, 0.1mol 2,2'-(ethylenedioxy)diethylamine was completely dispersed in 100mL of N,N dimethyl In the acetamide solution, equimolar 4,4-diaminodiphenyl ether was added in 4 times, and reacted for 8 hours after the addition, the solution was brown and viscous, and polyamic acid (PAA) was obtained.

[0034] (3) In an argon atmosphere at -10°C, equal volumes o...

Embodiment 2

[0036] (1) Synthesis of soft-segment EM based on hydrogen bond self-healing: First, 0.1mol 2,2'-(ethylenedioxy)diethylamine was dispersed in 100mL of ultra-dry N,N dimethylacetamide. Inject argon, and stir at -5°C for 30 min. Then, 0.1 mol of dicyclohexylmethane-4,4′-diisocyanate was dispersed in 20 mL of ultra-dry N,N dimethylacetamide. Then, the dicyclohexylmethane-4,4'-diisocyanate solution was slowly dropped into the reactor and continued to react for 8 hours to obtain a soft segment EM dispersion with hydrogen bond self-healing.

[0037] (2) Synthesis of polyamic acid (PAA): Firstly, at -5°C, under argon atmosphere, 0.1mol 2,2'-(ethylenedioxy)diethylamine was completely dispersed in 100mL of N,N dimethyl In the acetamide solution, equimolar 4,4-diaminodiphenyl ether was added in 3 times, and reacted for 15 hours after the addition, the solution was brown and viscous, and polyamic acid (PAA) was obtained.

[0038] (3) In an argon atmosphere at -5°C, equal volumes of poly...

Embodiment 3

[0040](1) Synthesis of soft-segment EM based on hydrogen bond self-healing: First, 0.1mol 2,2'-(ethylenedioxy)diethylamine was dispersed in 100mL of ultra-dry N,N dimethylacetamide. Inject argon, and stir at -10°C for 30 minutes. Then, 0.1 mol of dicyclohexylmethane-4,4′-diisocyanate was dispersed in 20 mL of ultra-dry N,N dimethylacetamide. Then, the dicyclohexylmethane-4,4'-diisocyanate solution was slowly dropped into the reactor and continued to react for 10 hours to obtain a soft segment EM dispersion with hydrogen bond self-healing.

[0041] (2) Synthesis of polyamic acid (PAA): Firstly, at -10°C, under argon atmosphere, 0.1mol 2,2'-(ethylenedioxy)diethylamine was completely dispersed in 100mL of N,N dimethyl To the acetamide solution, add equimolar 4,4-diaminodiphenyl ether in 3-4 times, react for 12 hours after the addition, the solution is brown and viscous, and polyamic acid (PAA) is obtained.

[0042] (3) In an argon atmosphere at -10°C, equal volumes of polyamic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com