Lithium battery positive electrode current collector, preparation method thereof, lithium battery and positive electrode thereof

A technology for positive electrode current collectors and lithium batteries, applied in the direction of electrode carriers/current collectors, battery electrodes, non-aqueous electrolyte battery electrodes, etc., can solve the problem of affecting the interface contact performance between the positive electrode and the electrolyte layer, the peeling off of the positive electrode active material, and the cycle life of the battery Decrease and other problems, to reduce the risk of thermal runaway, reduce quality, reduce the effect of specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

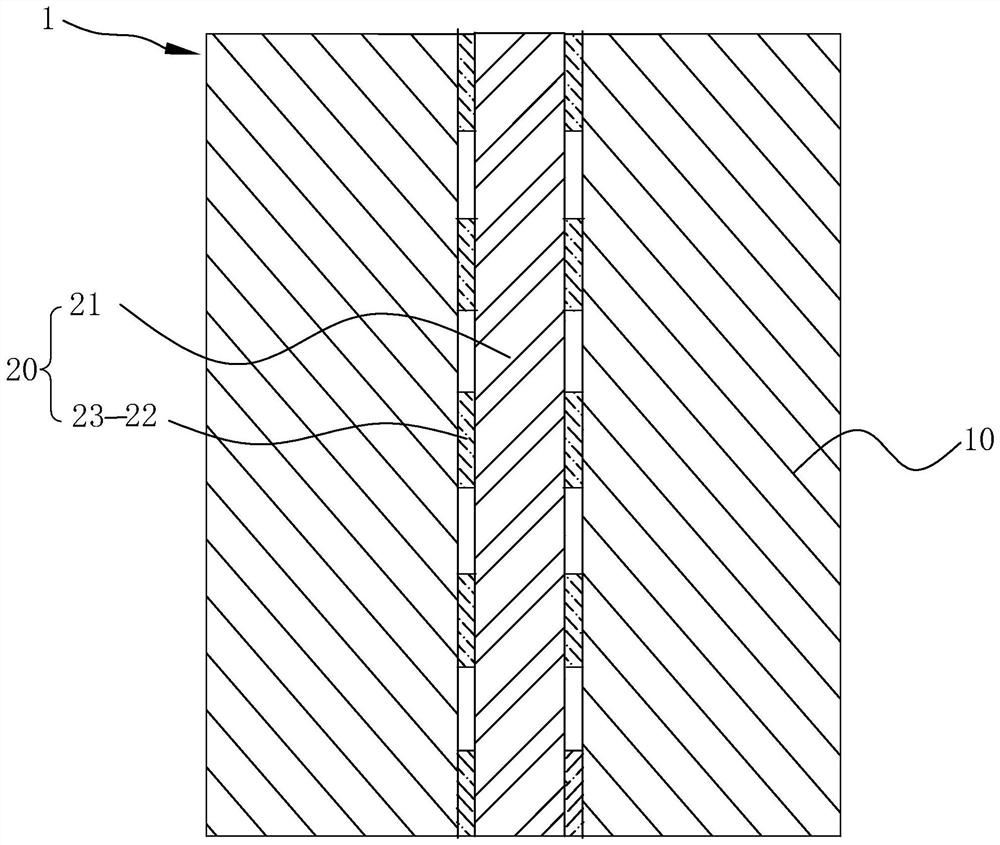

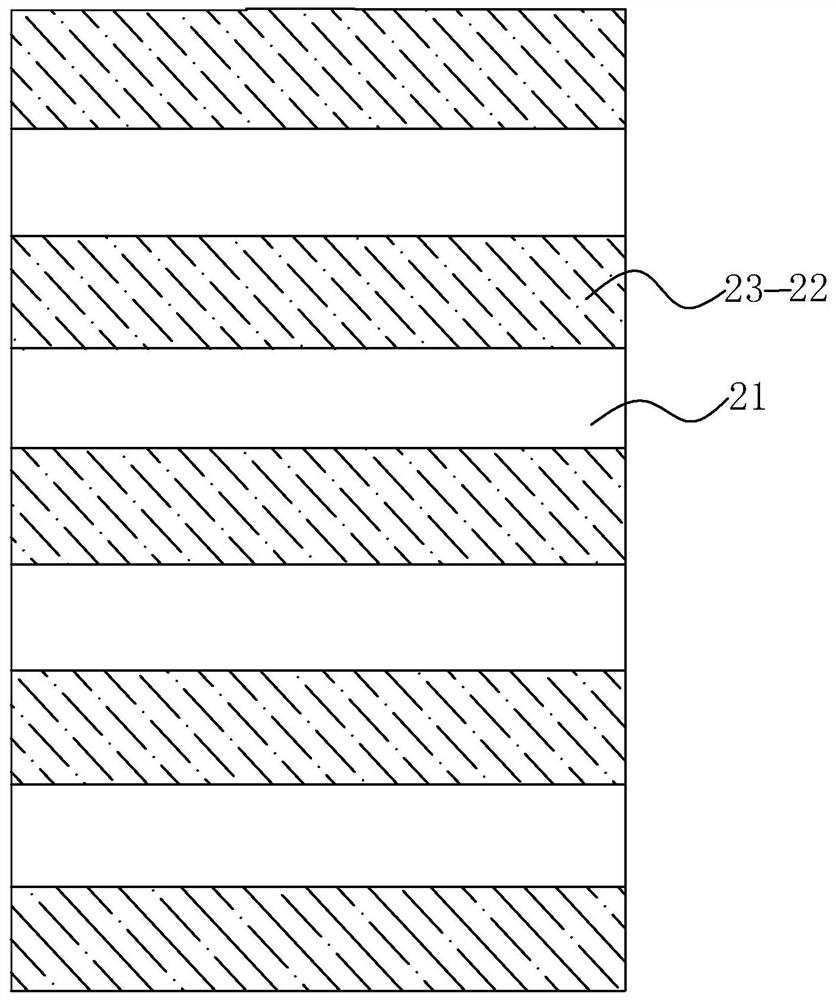

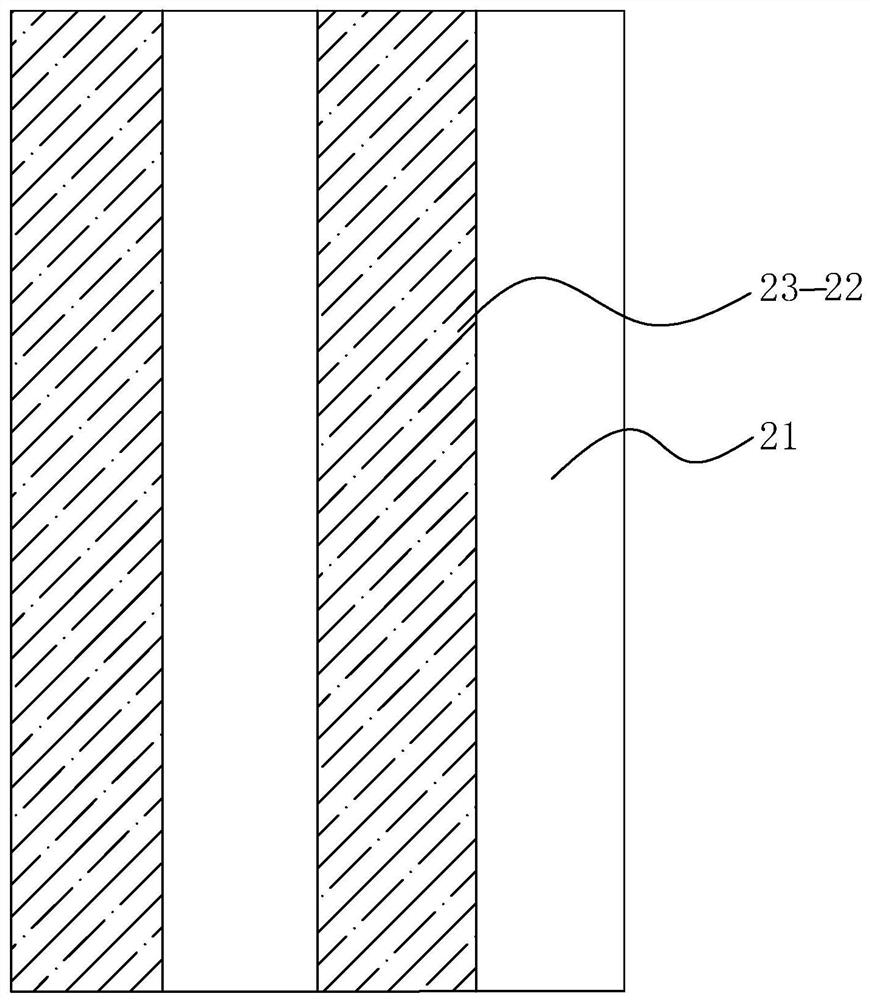

[0041] Embodiment 1, a lithium battery positive current collector, which includes a polyethylene film (polymer film), aluminum metal regions are arranged on both sides of the polymer film, and the two ends of the aluminum metal region are along the width direction of the polymer film set, and the aluminum metal area is provided with a plurality of intervals along the length direction of the polymer film; the aluminum metal area is provided with an aluminum metal layer, and the area of the aluminum metal layer is 50% of the area of the polymer film; and the positive current collector is as follows The operation prepares:

[0042] Cut out the release paper film according to the shape of the aluminum metal area, cover it on the surface of the polyethylene film, make the exposed part match the shape of the aluminum metal area, and obtain a semi-finished film; then place the semi-finished film in the vacuum magnetron sputtering equipment, aluminum As a target material, aluminum...

Embodiment 2

[0044] Embodiment 2, a lithium battery cathode current collector, differs from Embodiment 1 in that the area of the aluminum metal layer is 60% of the area of the polymer film.

Embodiment 3

[0045] Embodiment 3, a lithium battery cathode current collector, differs from Embodiment 1 in that the area of the aluminum metal layer is 40% of the area of the polymer film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com