Processing method and device for improving quality of silicon carbide substrate

A technology for silicon carbide substrates and processing devices, which is applied in chemical instruments and methods, cleaning methods using gas flow, cleaning methods and utensils, etc. Increase the surface roughness of the substrate and other issues to avoid secondary pollution or scratches, improve epitaxy quality, and reduce manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

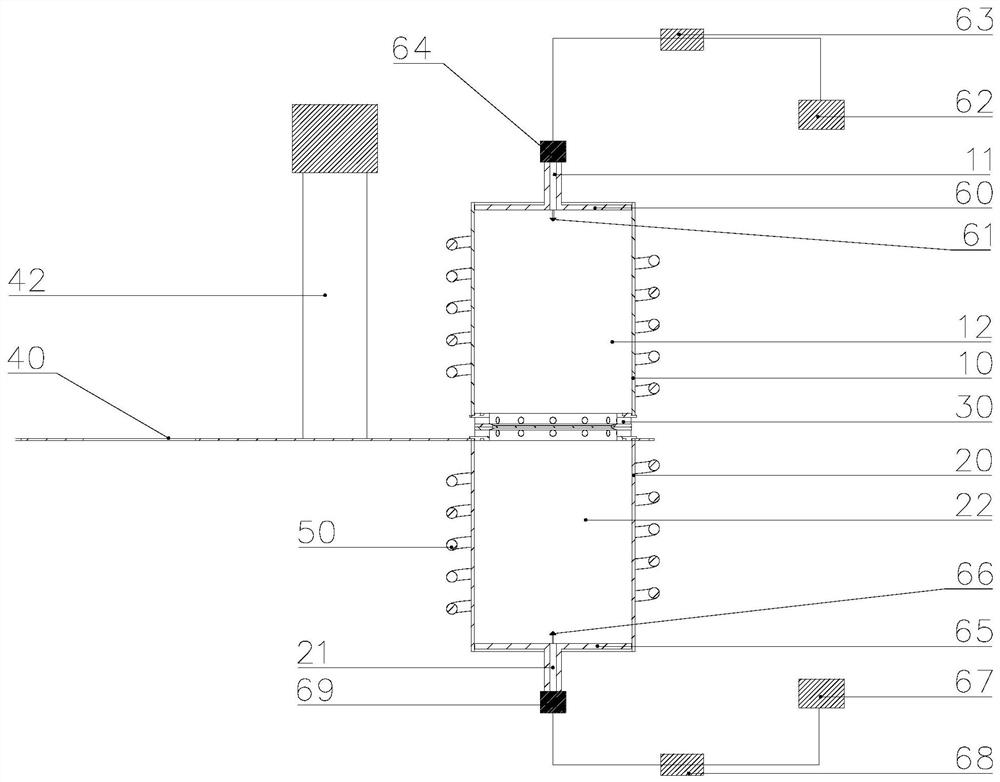

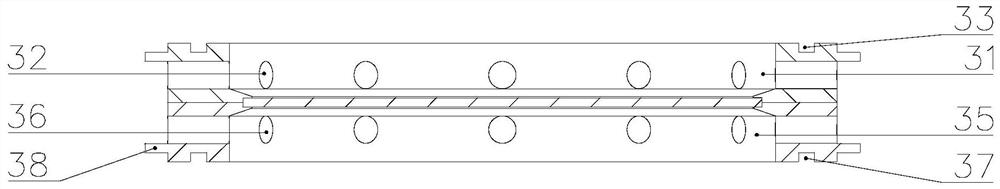

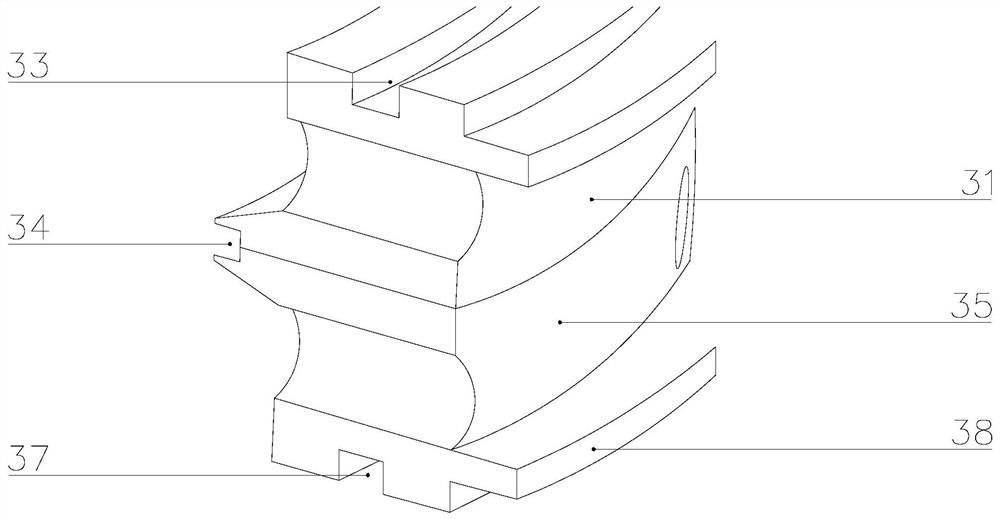

[0066] refer to Figure 1-5 , an embodiment of the present application discloses a processing device for improving the quality of a silicon carbide substrate, the processing device includes: an upper casing 10 and a lower casing 20, and the silicon carbide substrate is placed on the upper casing 10 and the lower casing between the body 20, so that the silicon carbide substrate and the upper shell 10 and the lower shell 20 respectively form a sealed first gas source chamber 12 and a second gas source chamber 22, wherein the first gas source chamber 12 is provided with the first An air inlet 11 and a first air outlet 32, a second air inlet 21 and a second air outlet 36 are arranged in the second gas source chamber 22, and the clean gas flows from the first air inlet 11 and the second air inlet 21 respectively After entering the first gas source chamber 12 and the second gas source chamber 22 for buffering, it flows to the upper surface and the lower surface of the silicon carbid...

Embodiment 2

[0096] This embodiment provides a treatment method for improving the quality of silicon carbide substrates. Silicon carbide crystals are prepared by physical vapor transport, wherein the number of particles with a particle size > 1 μm in the growth surface of the seed crystal is 15 atoms / cm 2 , surface roughness 1 μm on the growth surface of the seed crystal The number of particles <1, the number of particles with a particle size of 0.5μm-1μm<1, the number of particles with a particle size of 0.1μm-0.5μm<3, the number of particles with a particle size of 0.02μm-0.1μm< 5.

[0097] The prepared silicon carbide crystal is subjected to cutting, grinding and polishing processes to obtain a silicon carbide substrate, and the device of any embodiment in Example 1 is used to clean the silicon carbide substrate prepared by the same method above. The processing method includes the following The above steps:

[0098] Preparation stage: place the silicon carbide substrate to be cleaned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com