Large-load core holder capable of integrating CT scanning and true triaxial experiment device

A core holder and CT scanning technology, applied in the field of rock mechanics and engineering, can solve problems such as fracture, shear fracture, and pressure cannot be increased, and achieve the effect of avoiding shear damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

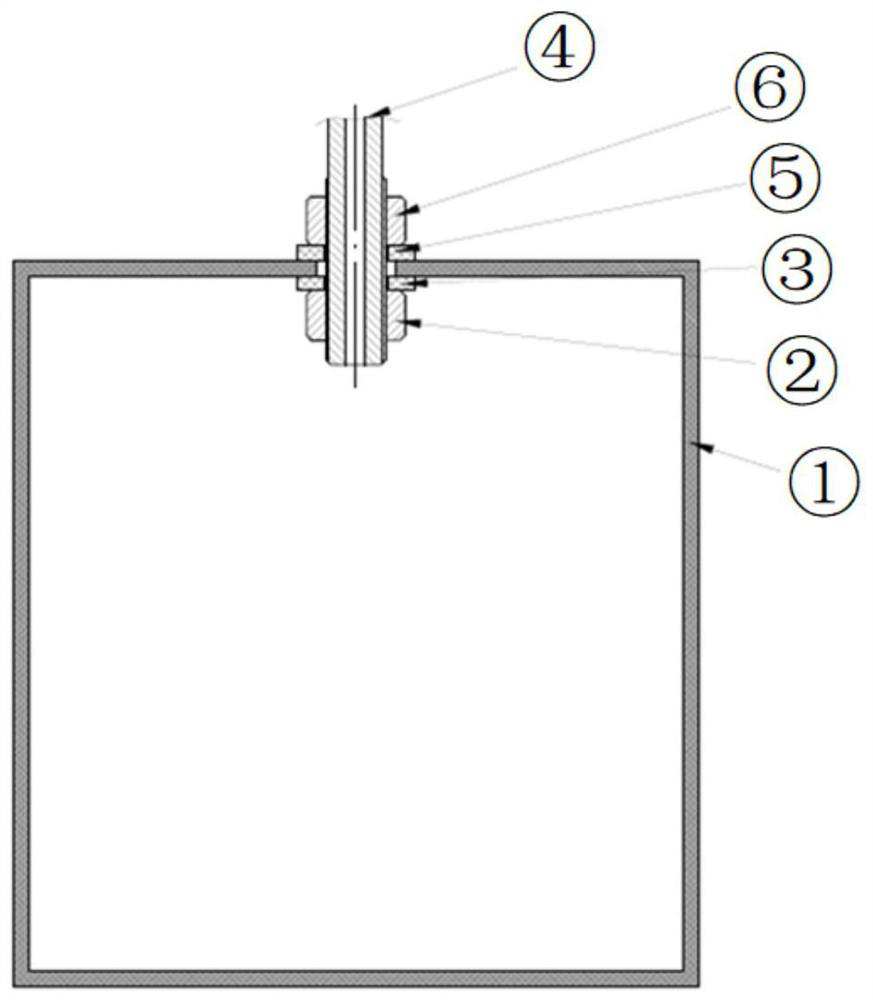

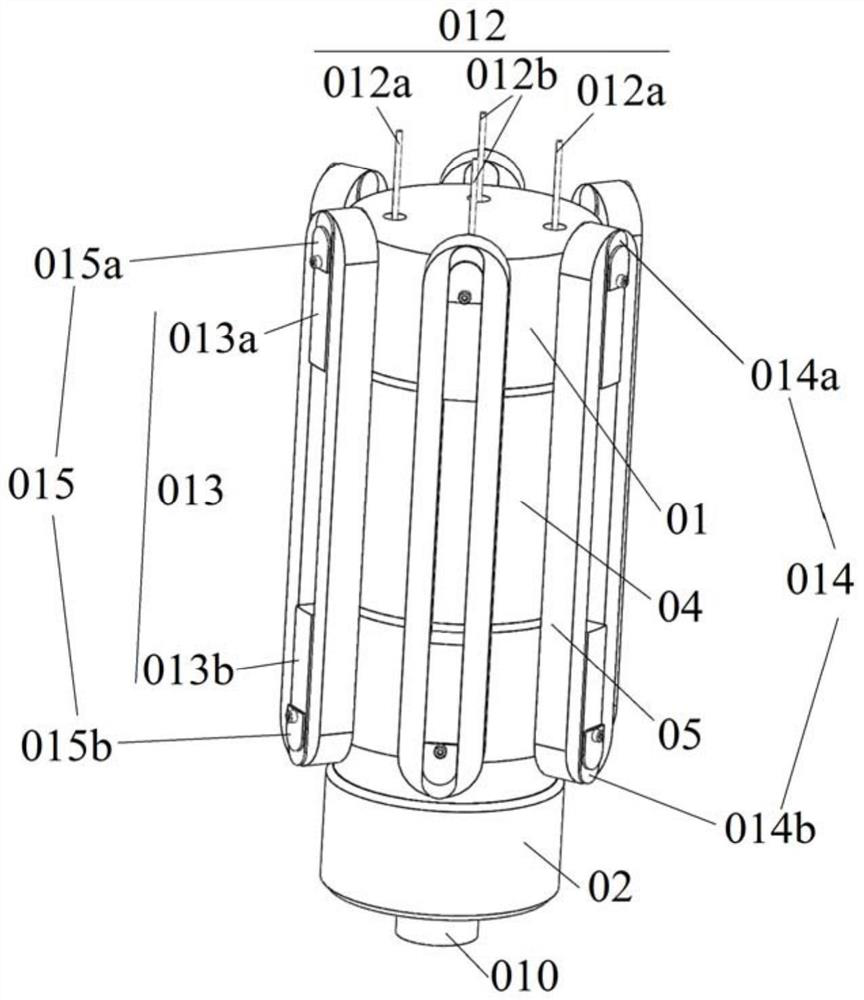

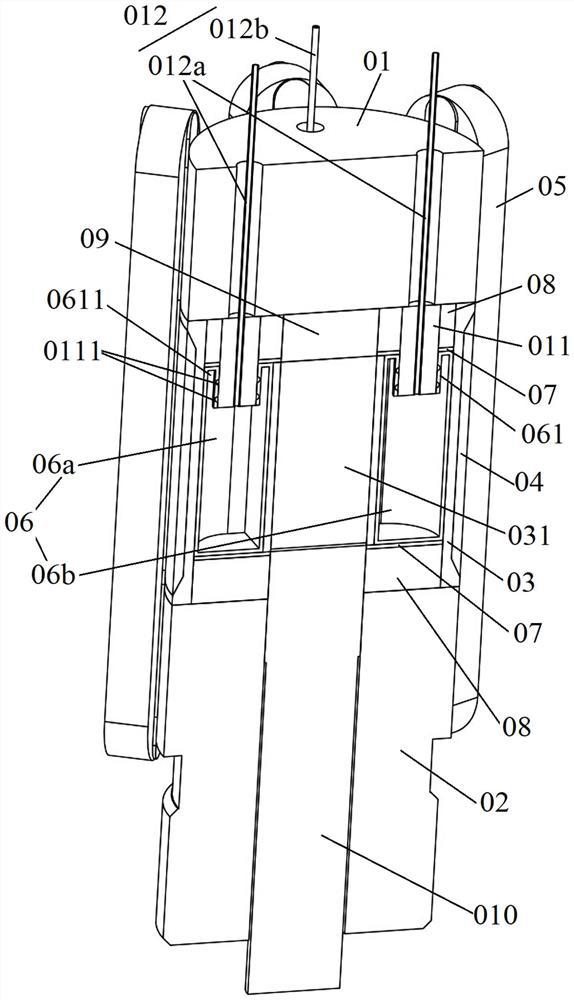

[0051] Please combine Figure 2 to Figure 5 As shown: a large-load core holder 1 that can be combined with CT scanning provided in this embodiment, including an upper force end 01, a lower force end 02, and two ends of non-metallic materials that can be penetrated by X-rays The cylindrical body 03 with both openings is provided with a circumferential pressure-bearing carbon fiber sleeve 04 on the outer circumference of the cylindrical body 03, and at least a pair of axial pressure-bearing carbon fiber rings 05 are arranged symmetrically on the outer axial direction of the cylindrical body 03. The hollow cavity of 03 is provided with a sample cavity 031, a left capsule storage cavity 032a symmetrically distributed on the left side of the sample cavity 031, a right capsule storage cavity 032b distributed on the right side, and a front capsule storage cavity distributed on the front side. 032c. The rear capsule storage cavity 032d distributed on the rear side, wherein: the left c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com