Lime underfiring degree on-line detection device

A detection device, lime technology, applied in the direction of removing a certain component weighing, filtration and separation, chemical/physical/physical-chemical stationary reactors, etc., can solve the problems of low detection efficiency and risk, and achieve a balanced weight distribution , improve the accuracy, improve the accuracy of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

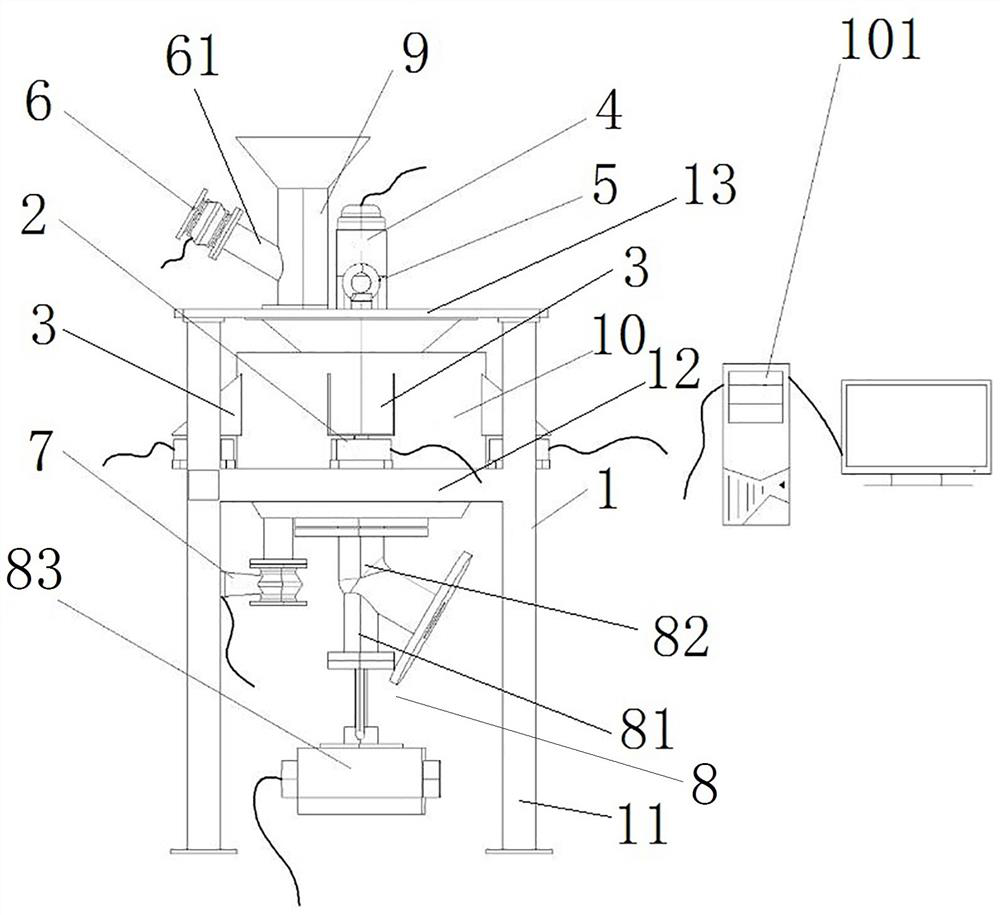

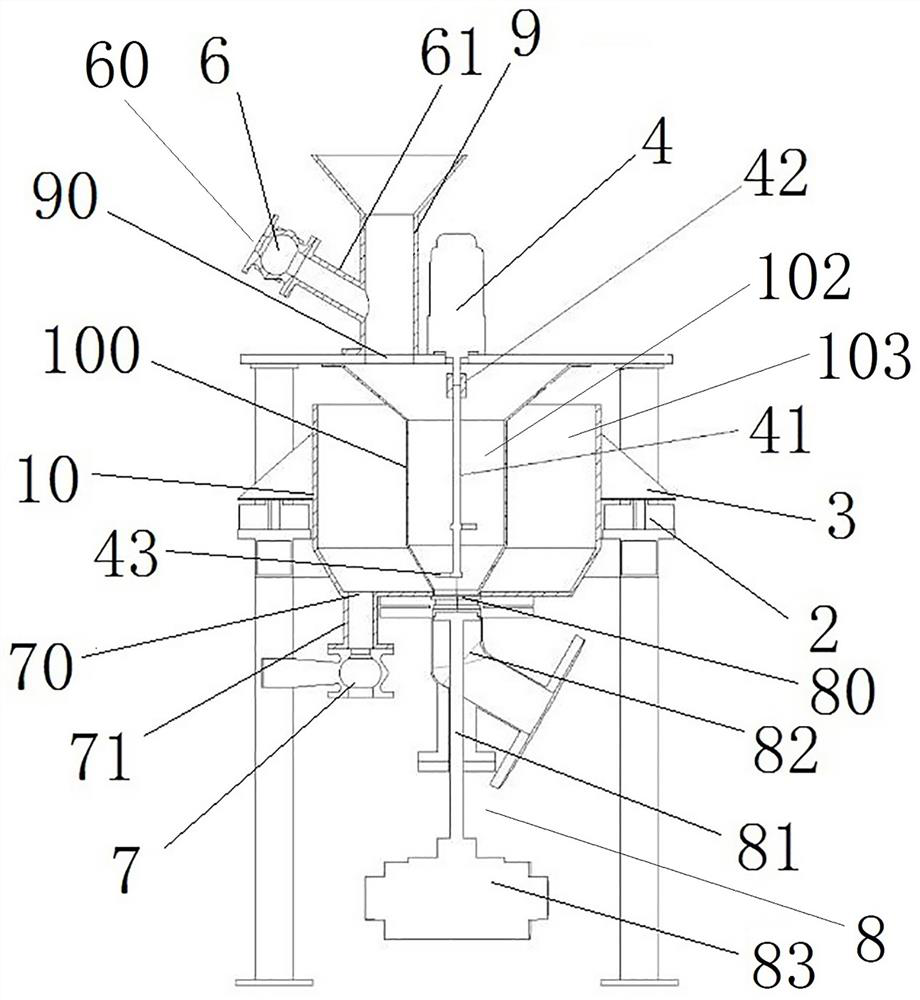

[0042] Such as figure 1 with figure 2 As shown, the on-line detection device for lime burning degree includes a frame 1, a reaction vessel 10 and a load cell 2. The reaction vessel 10 is used to hold lime samples, and the load cell 2 is used to measure the weight of the reaction vessel. The heavy sensor 2 is supported and installed on the rack 1 .

[0043] The frame 1 includes four uprights 11, the four uprights 11 are arranged in four different directions at intervals, each upright 11 extends along the up and down direction, and the middle parts of the two uprights 11 arranged in the same plane are fixedly connected by a cross bar 12 , the top of each column 11 is provided with a cover plate 13 , the cover plate 13 forms a complete frame 1 together with the column 11 and the cross bar 12 .

[0044] The top of the cover plate 13 is provided with a feed pipe 9 and lifting screws 5 at intervals, and the lifting screws 5 are fixedly connected with the cover plate 13, so that the...

Embodiment 2

[0057] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, a stirring shaft 41 is provided in the filter screen 100, a drive motor 4 is provided on the cover plate 13, and the drive motor 4 drives the stirring shaft 41 to rotate to accelerate lime Sample response. However, in this embodiment, no stirring shaft is installed in the filter screen, and the drive motor is canceled at the same time, and the drain valve is in a normally open state at this time, and water is always added to the filter screen until the lime sample is fully reacted, and the sample residue and reaction are measured. The total weight of the container G 2 .

Embodiment 3

[0059] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the drain valve 7 is hoisted below the reaction vessel 10 through the drain pipe 71 . In this embodiment, a drain valve seat is provided on the frame, and a drain valve is supported on the support of the drain valve seat, and the drain valve communicates with the drain port through a flexible pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com