Highway bridge damping and buffering support

A technology for highway bridges and shock absorbers, which is applied in bridges, bridge construction, bridge parts, etc., can solve problems such as cracking and voiding, small deformation capacity, and abnormal deformation of bearings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

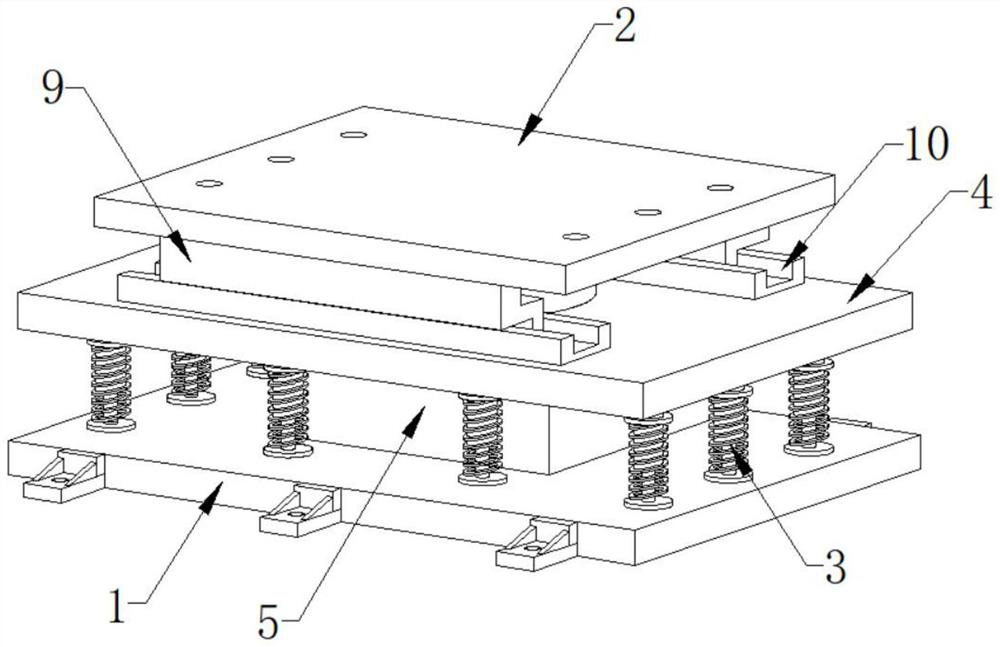

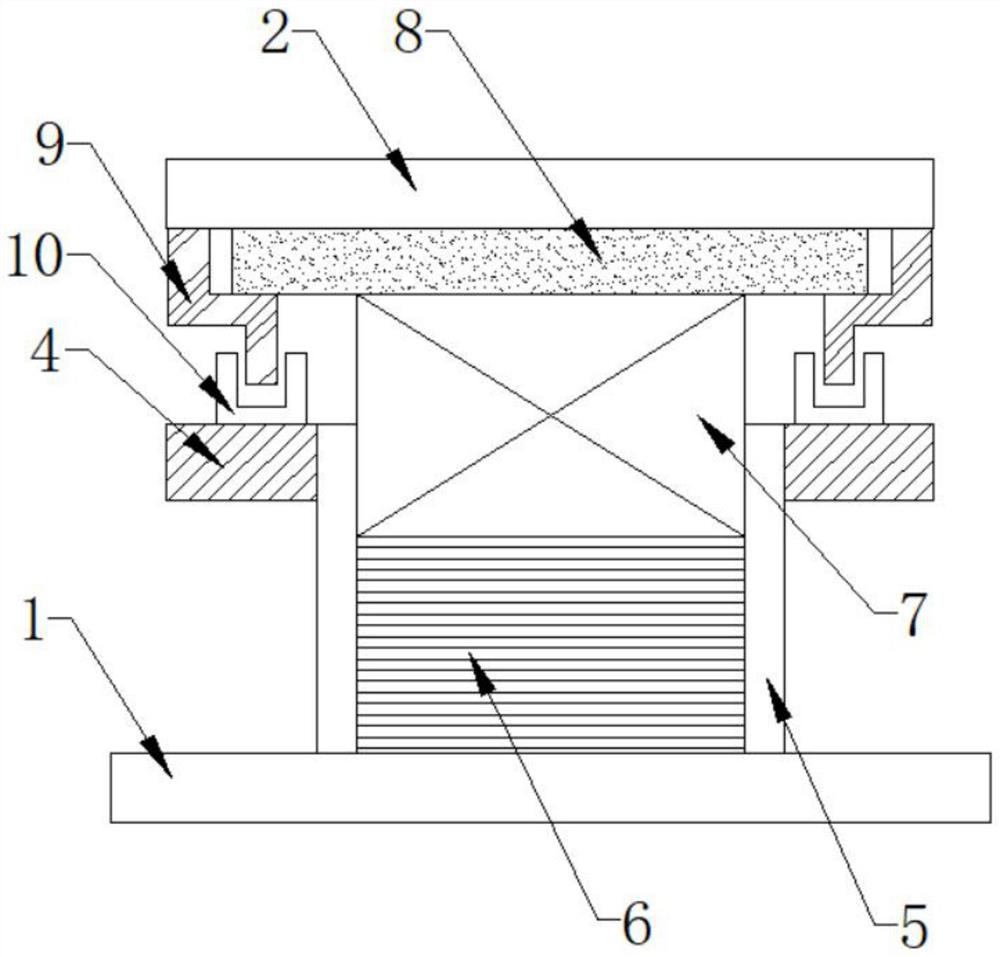

[0022] Such as Figure 1-3 As shown, the present invention provides a road bridge damping buffer bearing, comprising a lower steel plate 1 and an upper steel plate 2, the top surface of the lower steel plate 1 is surrounded by a plurality of first spring struts 3, and the first spring struts 3 The top is connected with a partition 4, and a dust cover 5 is installed in the middle of the top surface of the lower steel plate 1, and the top of the dust cover 5 penetrates the partition 4, and the inside of the dust cover 5 is embedded with a buffer base 6, and the top of the buffer base 6 A shock absorbing device 7 is provided, the top of the shock absorbing device 7 is connected with a slide plate 8, and the front and rear sides of the bottom surface of the upper steel plate 2 are provided with relative limit flaps 9, and the slide plate 8 is located between the limit fold plates 9 , The bottom end of the limiting flap 9 is provided with a groove seat 10 .

[0023] Further, the d...

Embodiment 2

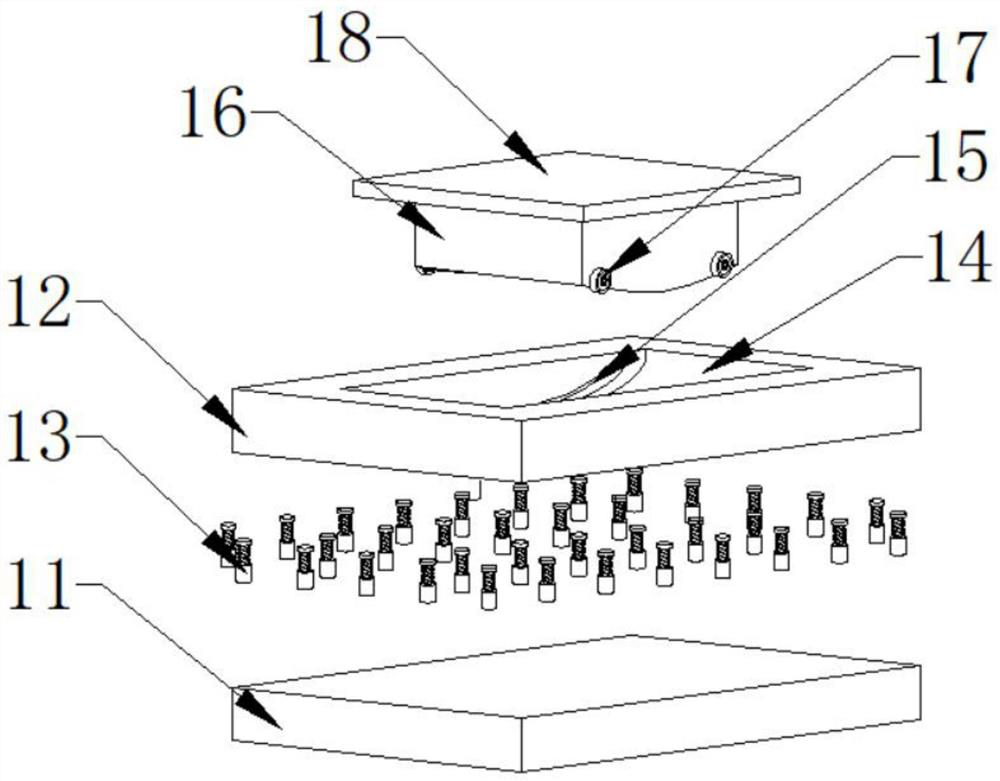

[0029] This embodiment and embodiment 1 are only improved on the shock absorber 7, and other places can be the same; further, the shock absorber 7 includes a circular base 19 and a support ball core 20, and the support ball core 20 is a hemispherical structure. And the bottom surface is provided with a spherical PTFE plate 21, the top surface of the circular base 19 has a container 22, and the spherical PTFE plate 21 is placed inside the container 22, and the volume of the supporting ball core 20 is greater than that of the container 22. volume, the top surface of the supporting ball core 20 is provided with a top plate 23, a plurality of third spring struts 24 are connected between the top surface of the top plate 23 and the circular base 19, and the top end of the top plate 23 is connected with the slide plate 8

[0030] Specifically, after the shock absorber 7 is vibrated by force, the top plate 23 shifts to one side and then drives the supporting ball core 20 to shift, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com